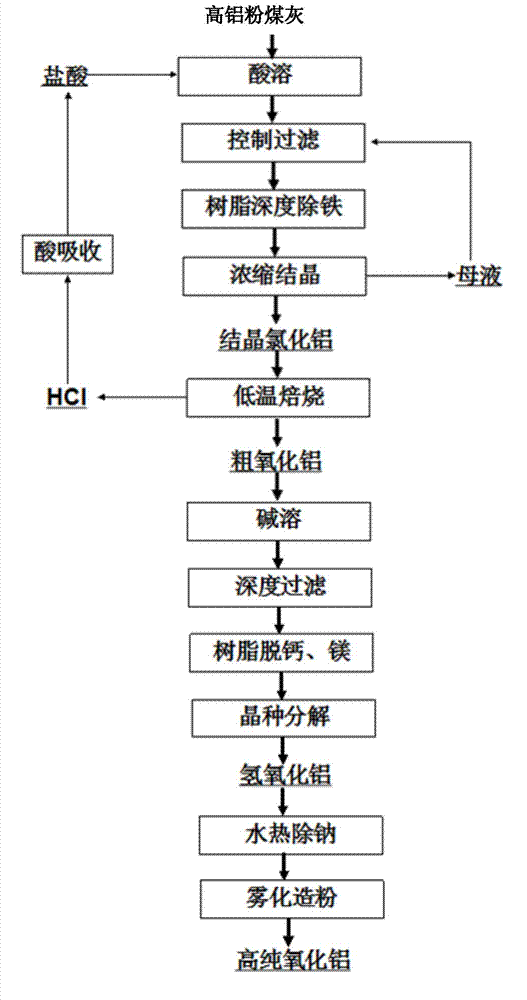

Method for preparing high-purity aluminum oxide from fly ash

A high-purity alumina and fly ash technology, applied in the chemical industry, can solve problems such as high cost, volume expansion, and unsatisfactory product purity, and achieve the effects of low production cost, low loss, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Add the high-alumina fly ash in Table 1 to hydrochloric acid for acid leaching reaction to obtain acid-soluble slurry. The mass ratio of fly ash to hydrochloric acid solution is 1:2, the mass fraction of hydrochloric acid solution is 25%, and the reaction temperature is 150 °C , the reaction time is 2h, and the reaction pressure is 0.5MPa. The acid-soluble slurry is passed through a plate-and-frame filter press (Zhongda Belight), and the pressure of the plate and frame is 300kPa; two plate-frames are selected in series for secondary filtration; the filter aid is α-cellulose. A crude aluminum salt solution is obtained after filtration. Pass the crude aluminum salt solution through the column of cation exchange resin Amberlite IR-116 (Dow resin in the United States) to remove iron, the temperature is 80°C, the speed of the solution passing through the column is 3 times the resin volume / h, and the way of passing through the column is from bottom to top The resin column ad...

Embodiment 2

[0065] Add the high-alumina fly ash in Table 1 to hydrochloric acid for acid leaching reaction to obtain acid-soluble slurry. The mass ratio of fly ash to hydrochloric acid solution is 1:3, the mass fraction of hydrochloric acid solution is 25%, and the reaction temperature is 150 °C , the reaction time is 2h, and the reaction pressure is 2MPa. The acid-soluble slurry is passed through a plate and frame filter press (Zhongda Belight), the pressure of the plate and frame is 450kPa; three plates and frames are selected in series for three-stage filtration; the filter aid is activated carbon. A crude aluminum salt solution is obtained after filtration. The thick aluminum salt solution adopts the extraction method to remove iron, the extractant is N235, the diluent is kerosene, the volume ratio of the extractant to the diluent=1:2, the volume ratio of the organic phase to the water phase=1:3, and the chlorinated Aluminum Refining Liquid. Detect the concentration of iron ions in ...

Embodiment 3

[0067]Add sulfuric acid to high alumina fly ash for acid leaching reaction to obtain acid soluble slurry, the mass ratio of fly ash to sulfuric acid solution is 1:2, the mass fraction of sulfuric acid solution is 25%, the reaction temperature is 130°C, and the reaction time is 2h , the reaction pressure is 0.5MPa. The acid-soluble slurry is passed through a plate and frame filter press (Zhongda Belight), the pressure of the plate and frame is 550kPa, and four plates and frames are selected in series for four-stage filtration, and the filter aid is diatomaceous earth. After filtration, coarse aluminum saline solution. Send the crude aluminum salt solution to the settling system with a settling temperature of 95°C and a settling time of 50 minutes to obtain crude aluminum sulfate semen; the settled slurry enters the washing device for washing at a washing temperature of 80°C. The aluminum sulfate crude semen is removed by extraction method, the extraction agent is P204, the dil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com