Production method for grinding steel-iron slag powder, mineral slag powder and steel slag powder by using vertical mill

A technology for iron and steel slag powder and a production method, which is applied to the field of vertical mill grinding of iron and steel slag powder, can solve the problems of different hardness, easy separation of iron, different activities, etc., so as to reduce investment and product manufacturing costs, and reduce production capacity. Consumption and cost, the effect of simplifying production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

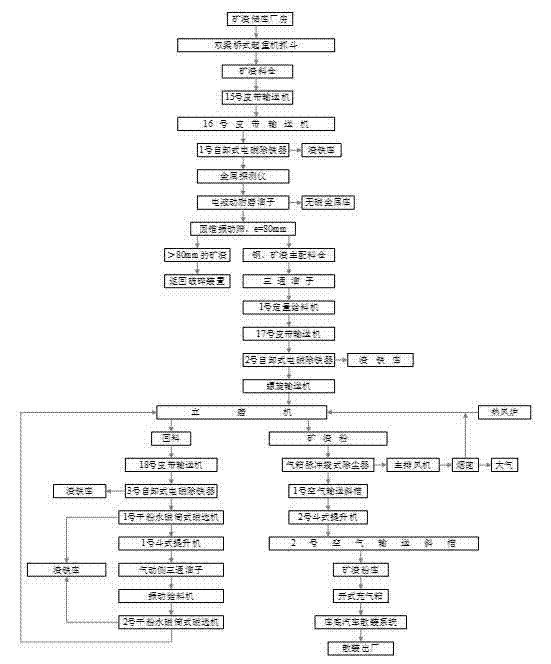

[0048] like image 3 As shown, the production method of slag powder: the slag stored in the mixed storage workshop is grabbed by the 20T driving grab into the slag silo and then transferred to the No. 16 belt conveyor outside the mixed storage workshop by the No. 15 belt conveyor. No. self-unloading electromagnetic iron remover to remove iron once, and then enter the electro-hydraulic wear-resistant slide to remove non-magnetic metal once after being detected by the metal detector, and then pass through the cone vibrating screen to crush the unbroken slag. The aperture of the screen is 80mm, and the slag with a particle size of less than 80mm is screened out into the steel and slag main batching bin (at this time, it is used as an independent slag batching bin, and the steel slag sub-batching bin is disabled at this time), and the slag with a particle size of ≥80mm is sent from the vibrating screen The bypass pipe is sent to the stacking warehouse, and after being crushed agai...

Embodiment 3

[0064] like Figure 4 As shown, the production method of steel slag powder: firstly, the steel slag tailings entering the vertical mill are respectively subjected to steel slag processing metal recovery treatment, and the slag entering the vertical mill is subjected to slag metal removal pretreatment. The specific steps are as in the first and second embodiments above, and will not be repeated here.

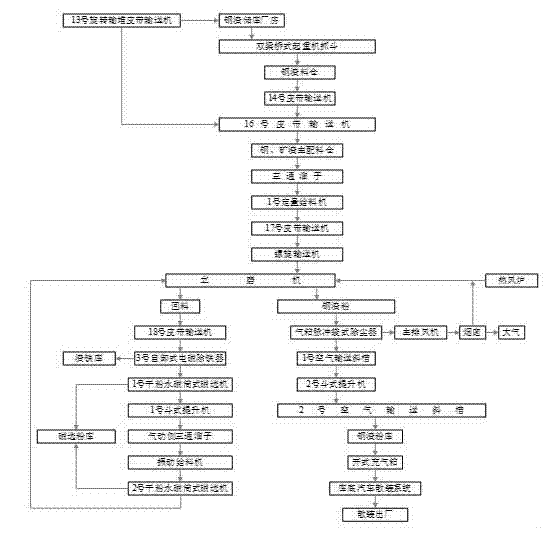

[0065] The steel slag tailings stored in the steel slag storage workshop are sent to the steel slag silo with a crane grab and sent to the No. 19 belt conveyor to the steel slag auxiliary batching bin, and sent to the No. 17 belt conveyor by the No. 2 quantitative feeder. From the steel and slag main batching bin, it is sent to the No. 17 belt conveyor by the No. 1 quantitative feeder. The iron slag is removed again by the No. 2 self-feeding electromagnetic iron remover, and the steel slag and slag components are mixed according to the ratio of 2-4:8-6, and then sent to the scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com