High-gradient magnetic separator

A high-gradient magnetic separator and sorting technology, applied in the direction of high-gradient magnetic separator, etc., can solve the problems of wasting water resources, reducing the processing capacity of equipment, and reducing the rotation speed of the sorting ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

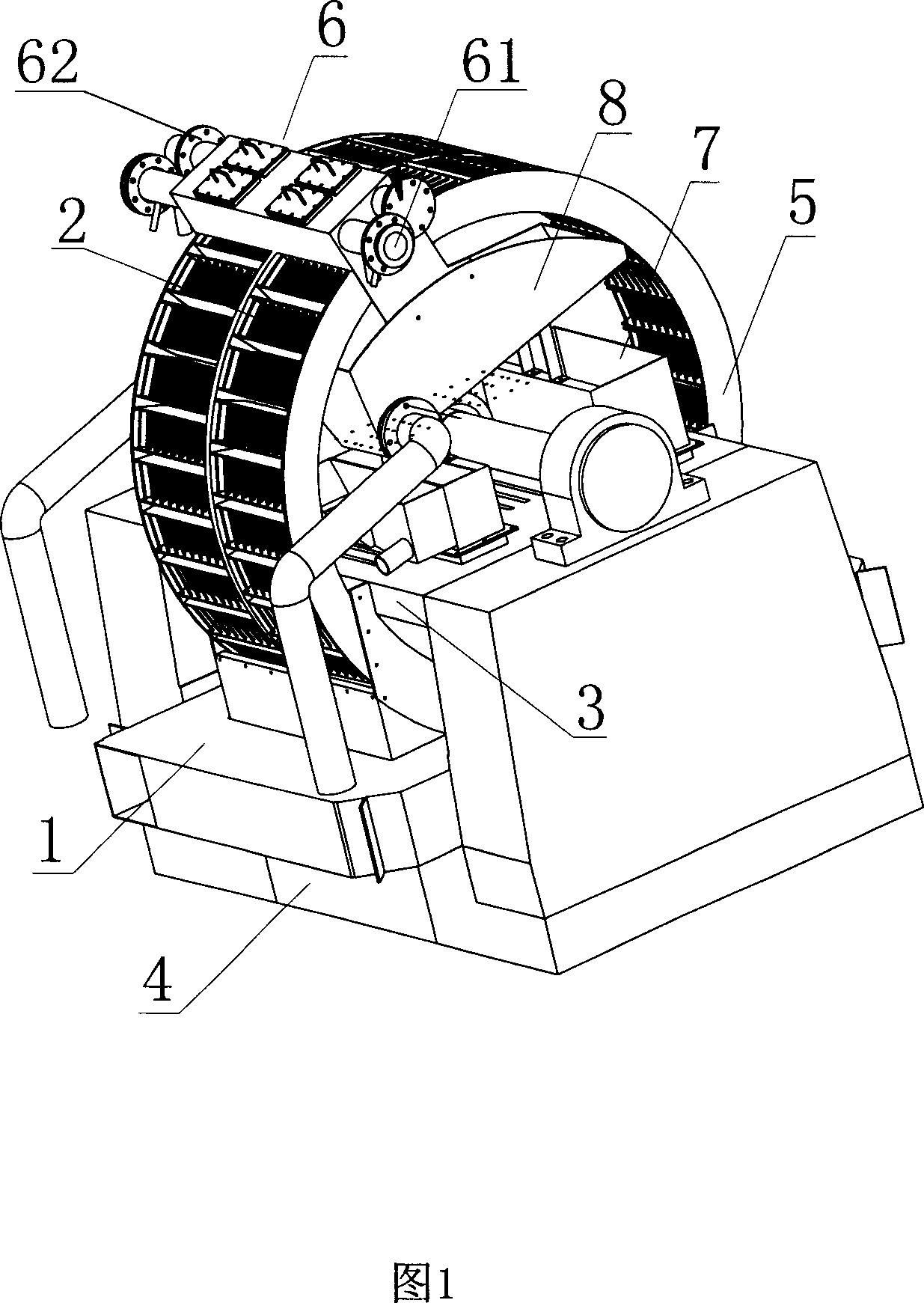

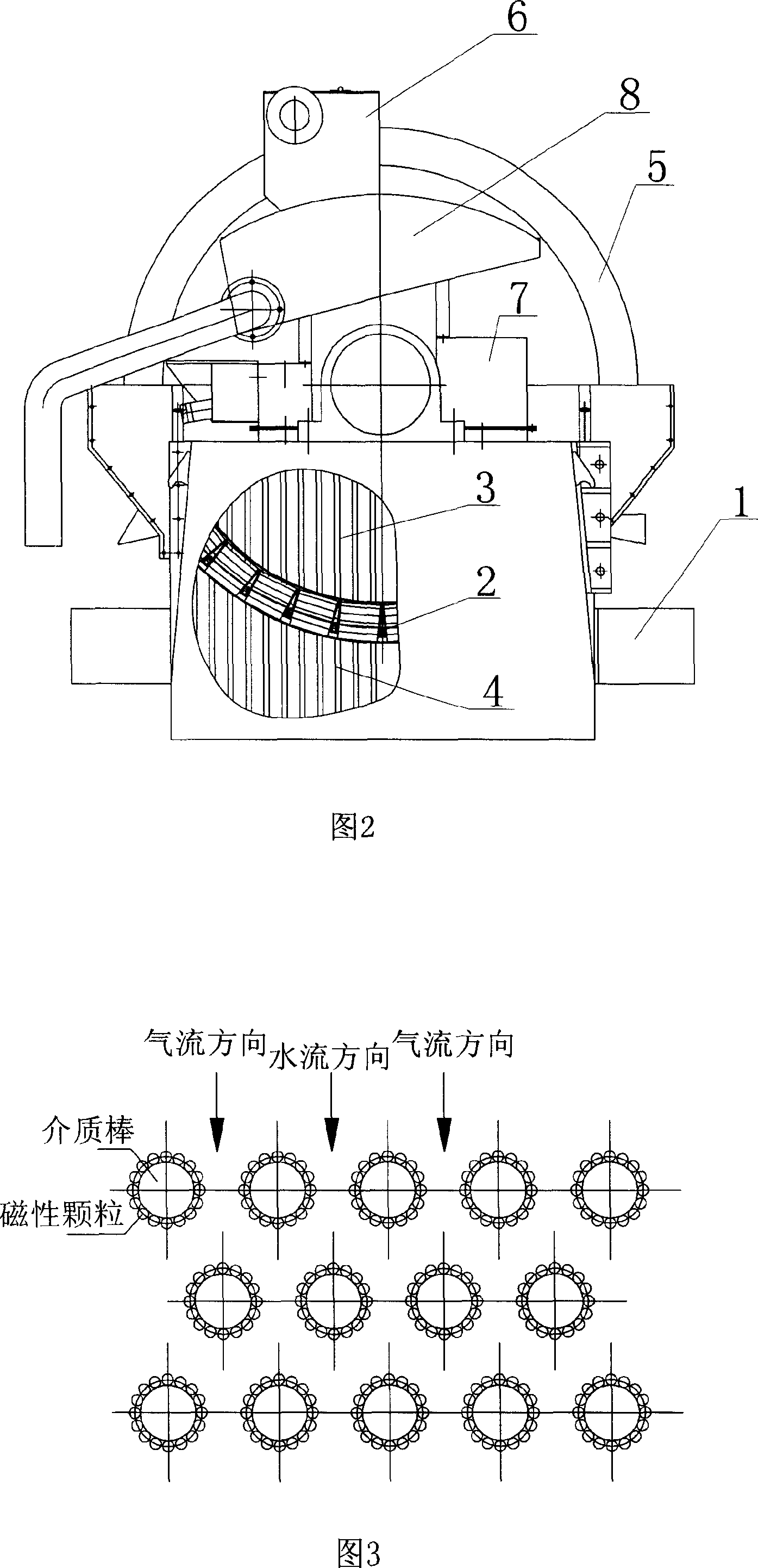

[0015] As shown in Figures 1 to 3, a high gradient magnetic separator according to the present invention includes a separation ring and its driving device, an ore feeding device 7, a concentrate unloading device 6 and a concentrate collecting device 8, wherein The sorting ring includes a swivel 5 and a magnetic gathering medium stack 2 installed on the swivel 5, the upper magnetic pole 3, the lower magnetic pole 4 and the excitation coil group 1 located inside and outside the swivel 5, and the swivel 5 is a vertical double ring The ring is equipped with a turntable connecting the double rings as a whole, and a shaft sleeve with a bearing is installed in the turntable. The above-mentioned ring body is divided into several spaces with the same volume by a number of partitions, and the magnetic gathering medium stack is fixed in the corresponding space. Among them, the above-mentioned magnetic gathering medium stack 2 is a rod medium, and the rod medium is fixed on a stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com