High gradient magnetic separator

a magnetic separator and gradient technology, applied in the direction of magnetic separation, separation process, filtration separation, etc., can solve the problems of limited fluid flow speed, difficult removal of particles with high remnant magnetism, and limited removal of particles during flushing, so as to improve the release of magnetic particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

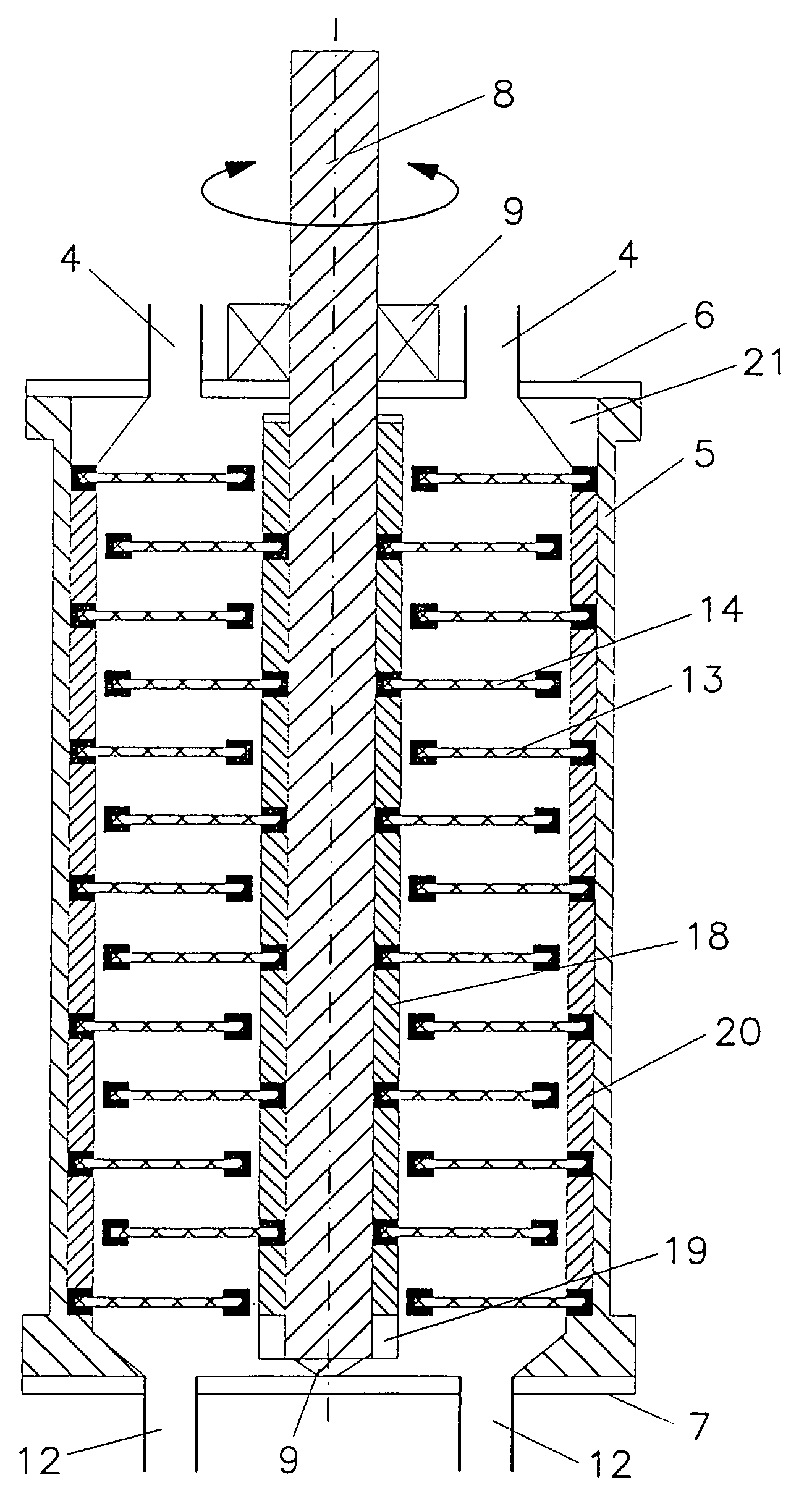

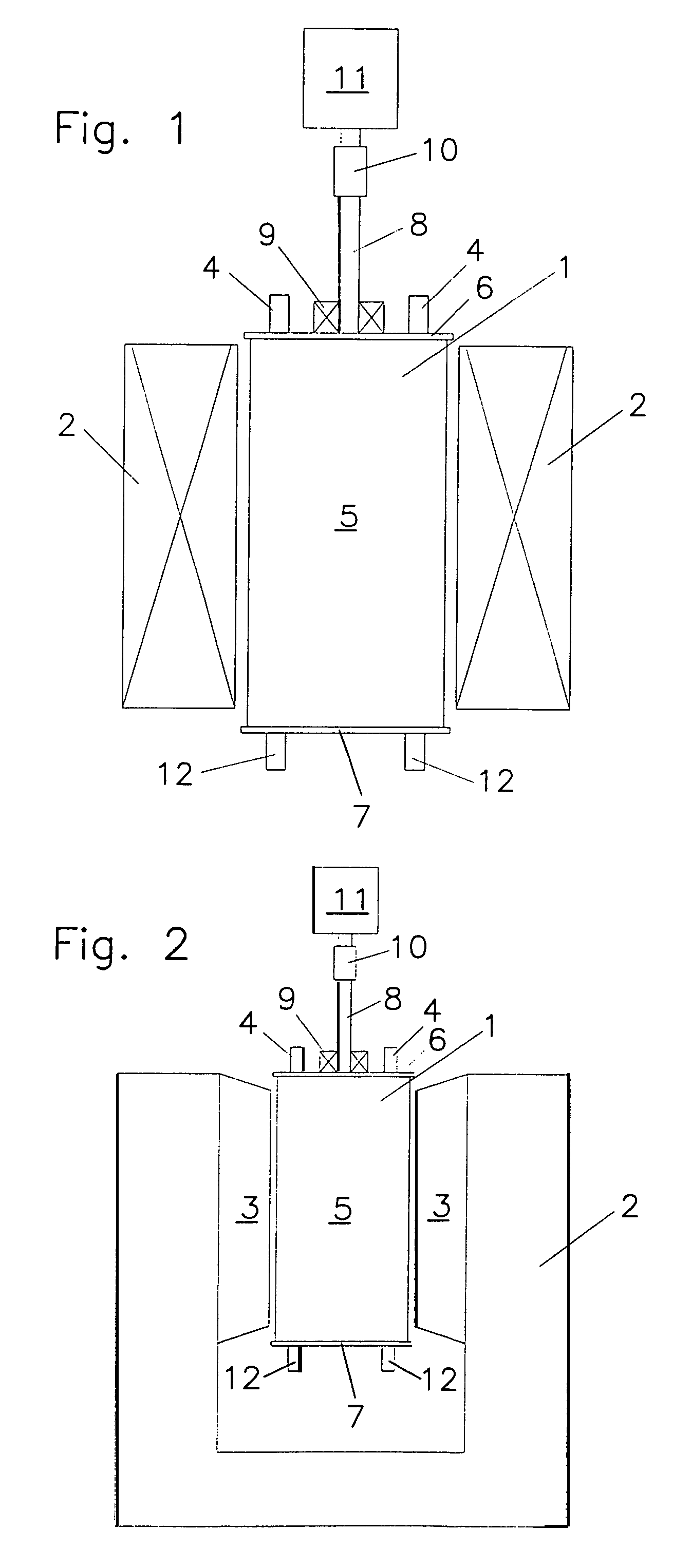

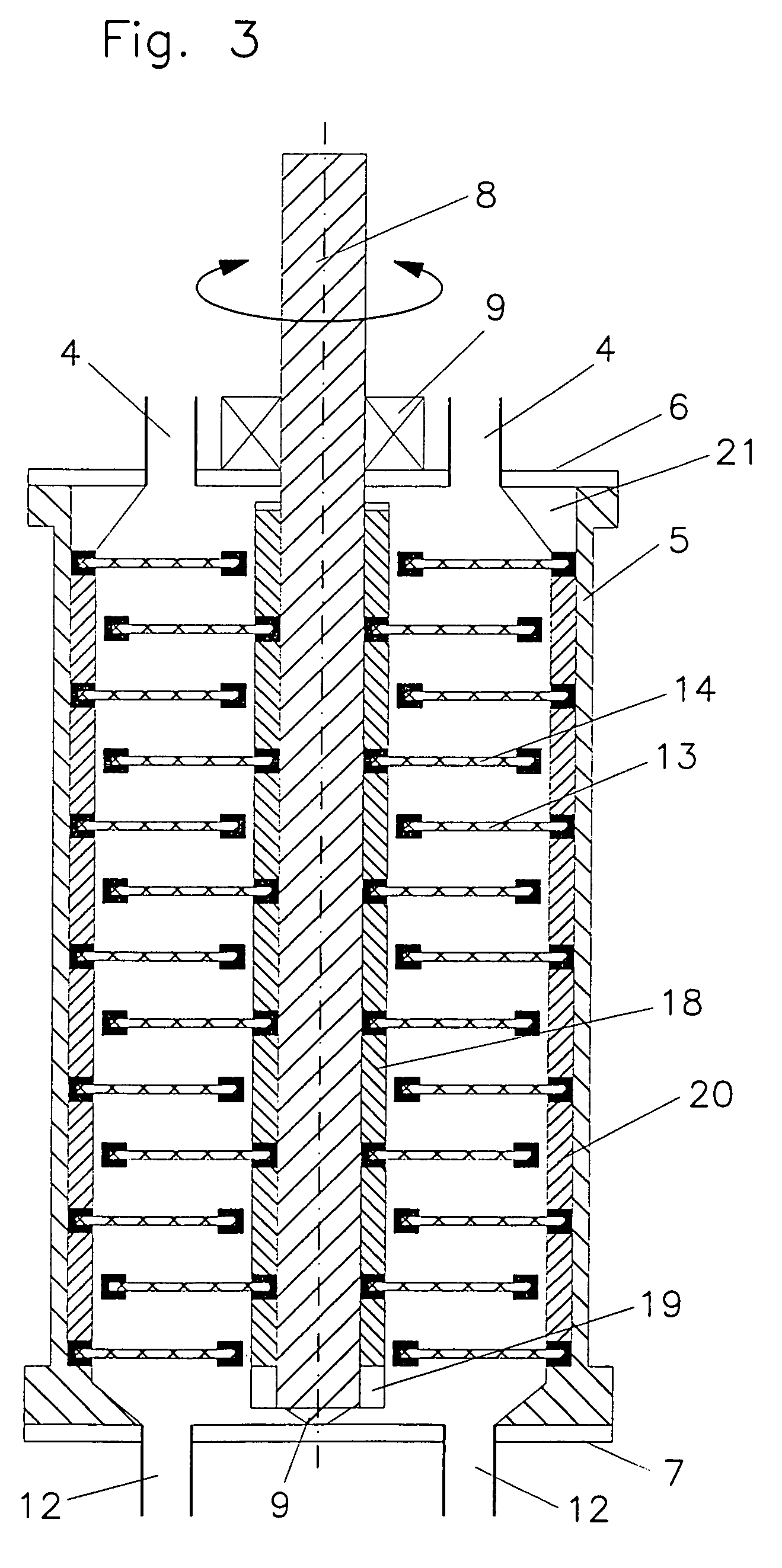

[0024]As shown in FIGS. 1 and 2, the high-gradient magnetic separator 1 is disposed in the direct effective range of a magnetic system 2, which serves as a field source. As magnetic field source preferably electromagnets (FIG. 1), superconductive magnetic systems or permanent magnetic systems (FIG. 2) are used wherein the high gradient magnetic separator 1 is disposed in the magnetic coil opening or, respectively, between the pole shoes 3.

[0025]The actual high gradient magnetic separator comprises several partial units, that is, an essentially cylindrical housing 5 which is closed axially by a lid 6 and a bottom plate 7. A shaft 8 is rotatably supported concentrically in the housing 5, that is, in the shown embodiment by bearing 9 in the lid and or the bottom plate 7 in a sealed manner and is connected to a drive 11 by way of a clutch 10. The shaft, the housing, the lid and the bottom plate all consist of non-magnetic material.

[0026]The core unit of the high gradient magnetic separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle sizes | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com