Continuous high gradient magnetic separator

A high-gradient magnetic separation and sorting technology, applied in the direction of high-gradient magnetic separators, can solve the problems of difficult separation of ultrafine particles and weak magnetic particles, high operation and maintenance costs, and difficult magnetic field switching operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

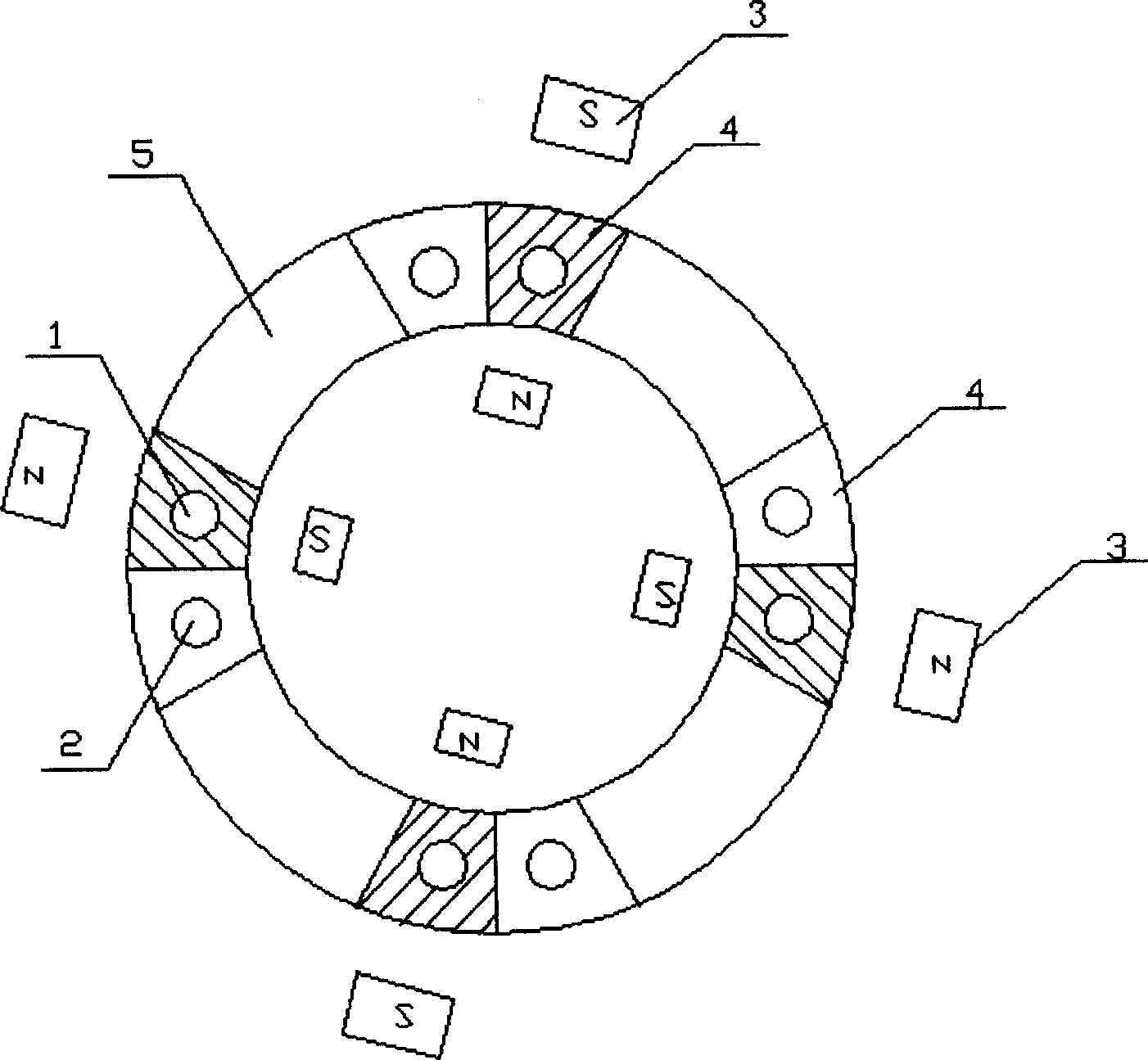

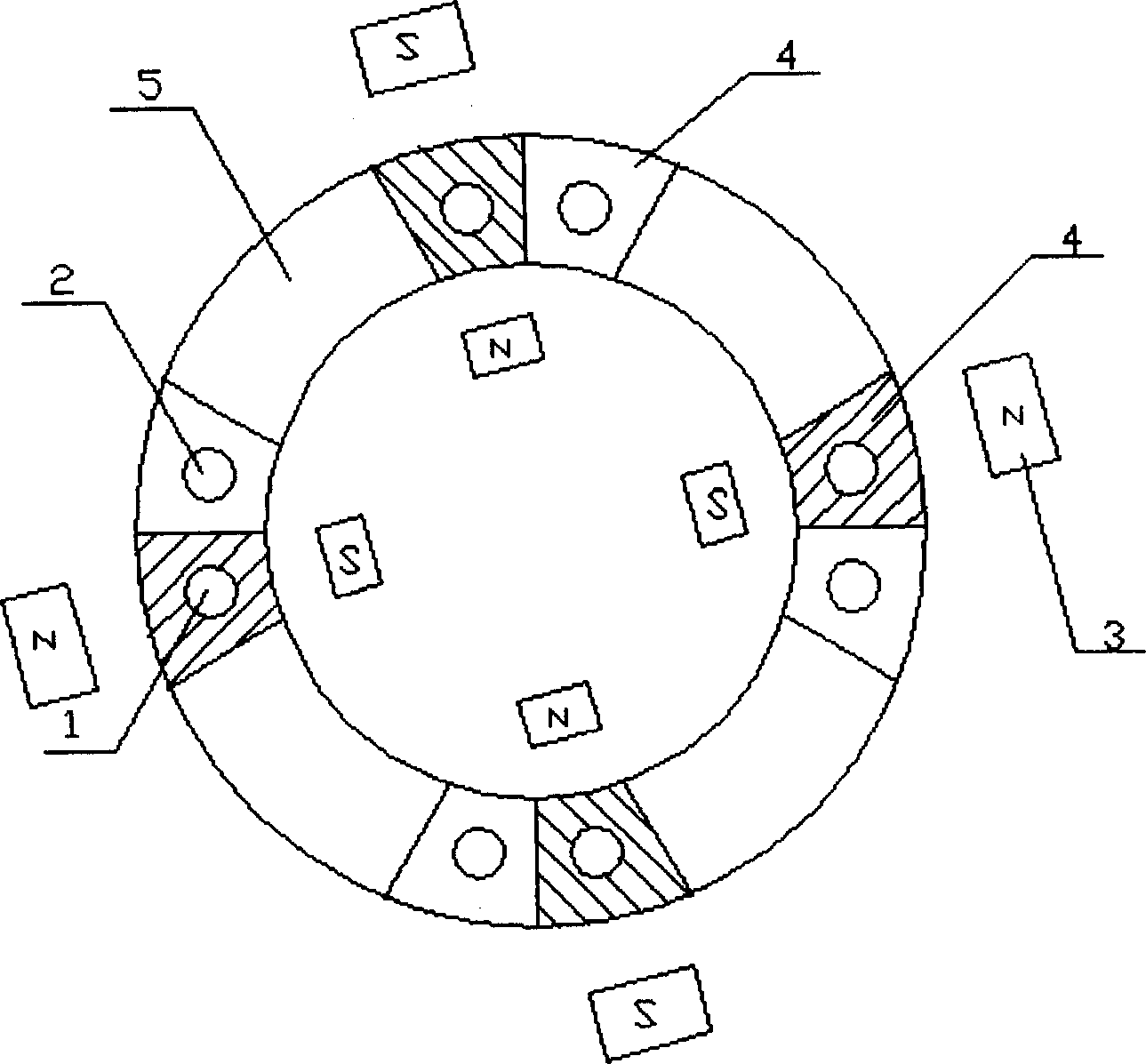

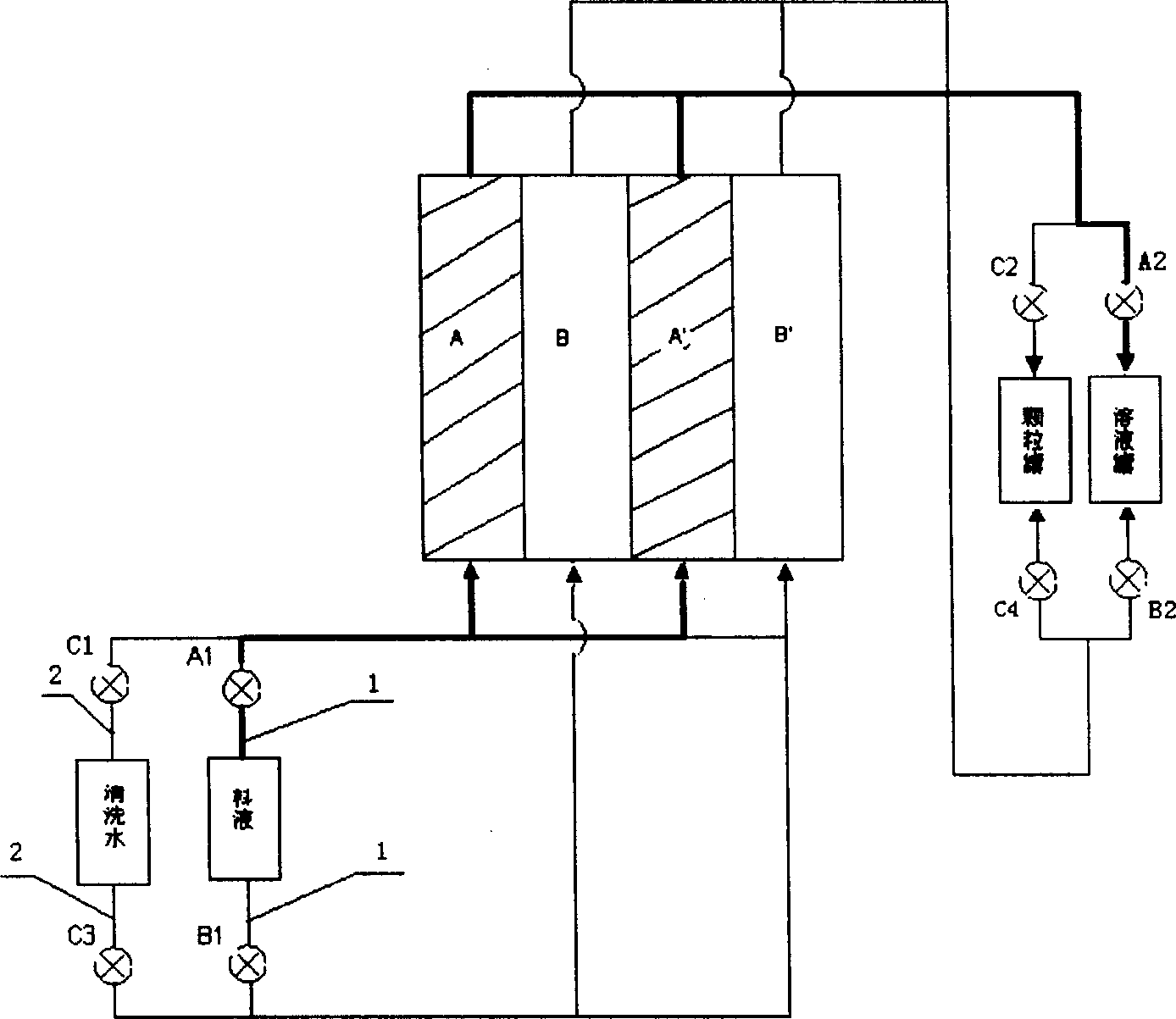

[0022] As shown in Figure 1 (a) and (b), a continuous high-gradient magnetic separator is composed of a plurality of separation chambers 4 connected to form a separation ring 5, and each separation chamber 4 is equipped with a feed pipe 1 and the cleaning water pipe 2, the feed pipe 1 and the cleaning water pipe 2 are all controlled by the electromagnetic valve described later. At least 4 pairs of C-shaped permanent magnets 3 are arranged around the sorting ring 5, and the magnetic field of the permanent magnets 3 is 600-4600 Oersted. The sorting chamber 4 is both a capture chamber and a flushing chamber in different operating periods, and the permanent magnet 3 periodically moves between the sorting chamber 4 (capture chamber and flushing chamber) to realize switching of the magnetic field while keeping the sorting chamber 4 stationary .

[0023] The sorting chamber 4 is in a sealed state, and is suitable for the separation of weakly magnetic tiny magnetic particles under hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com