Residue conditioning system

a technology of residue and conditioning system, which is applied in the direction of gasification process details, inorganic chemistry, combustible gas production, etc., can solve the problems of insufficient disposal of solid waste, inability to adequately address prior systems and processes, and less desirable disposal of waste material by incineration, etc., to achieve the effect of optimizing the conversion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

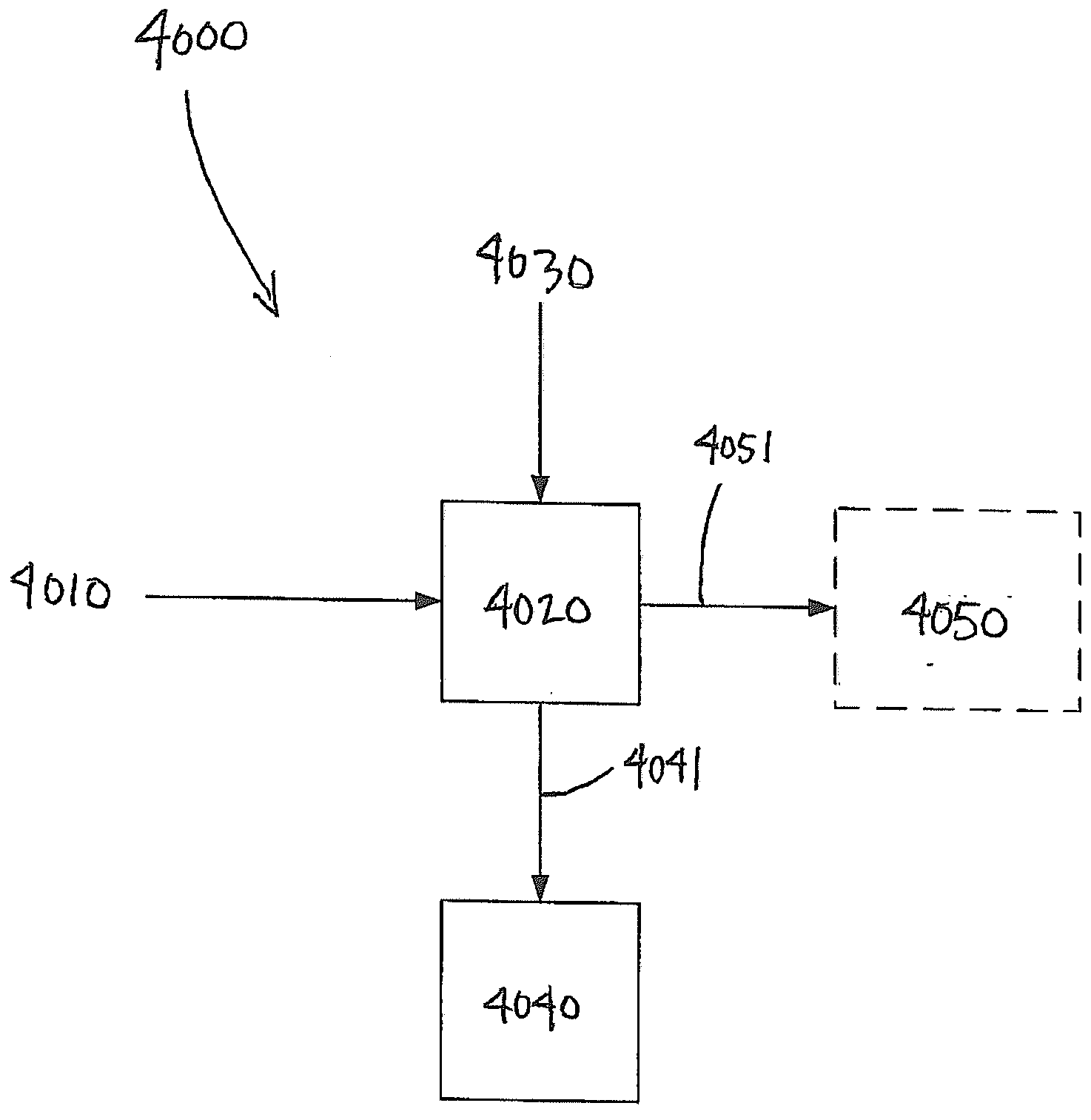

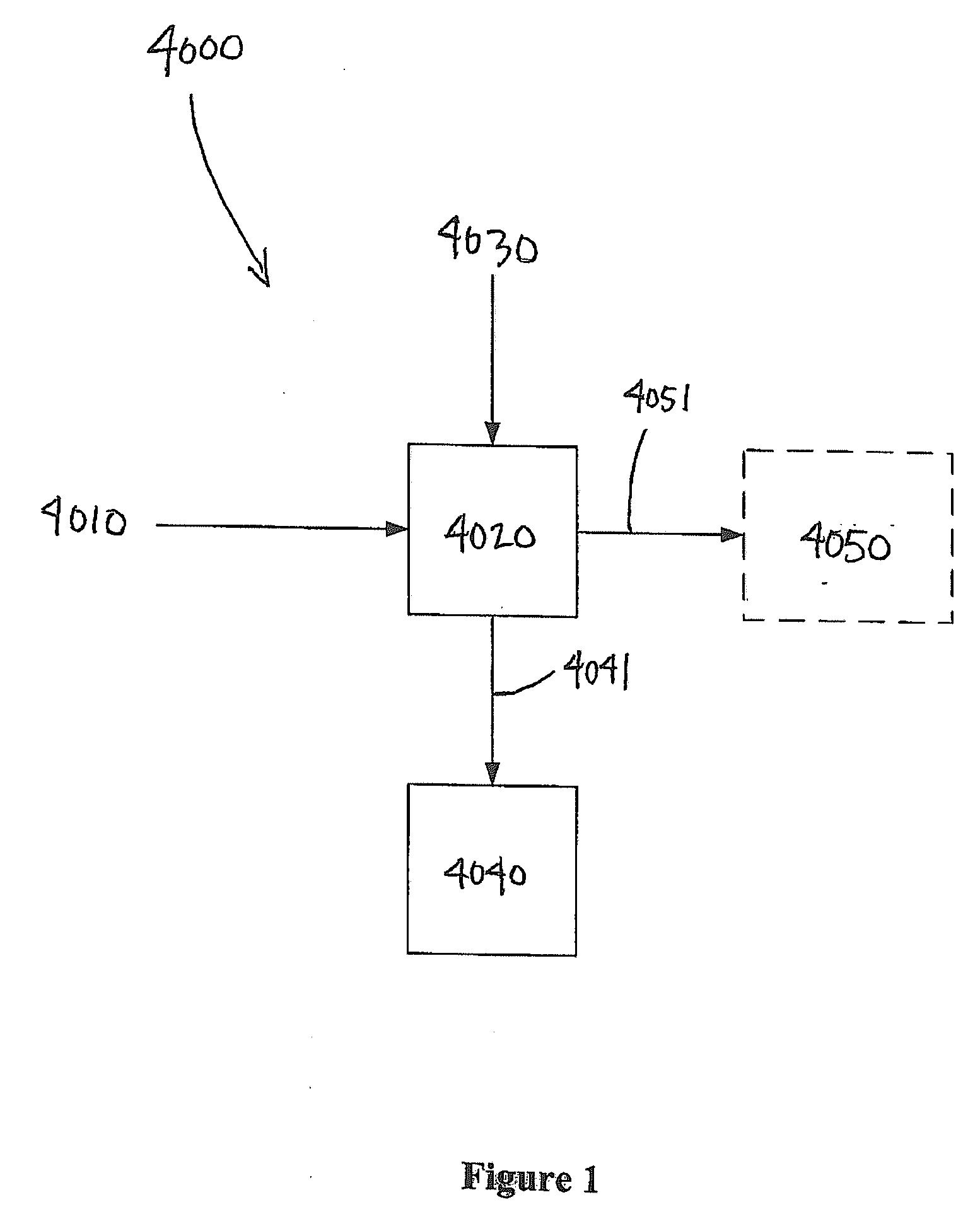

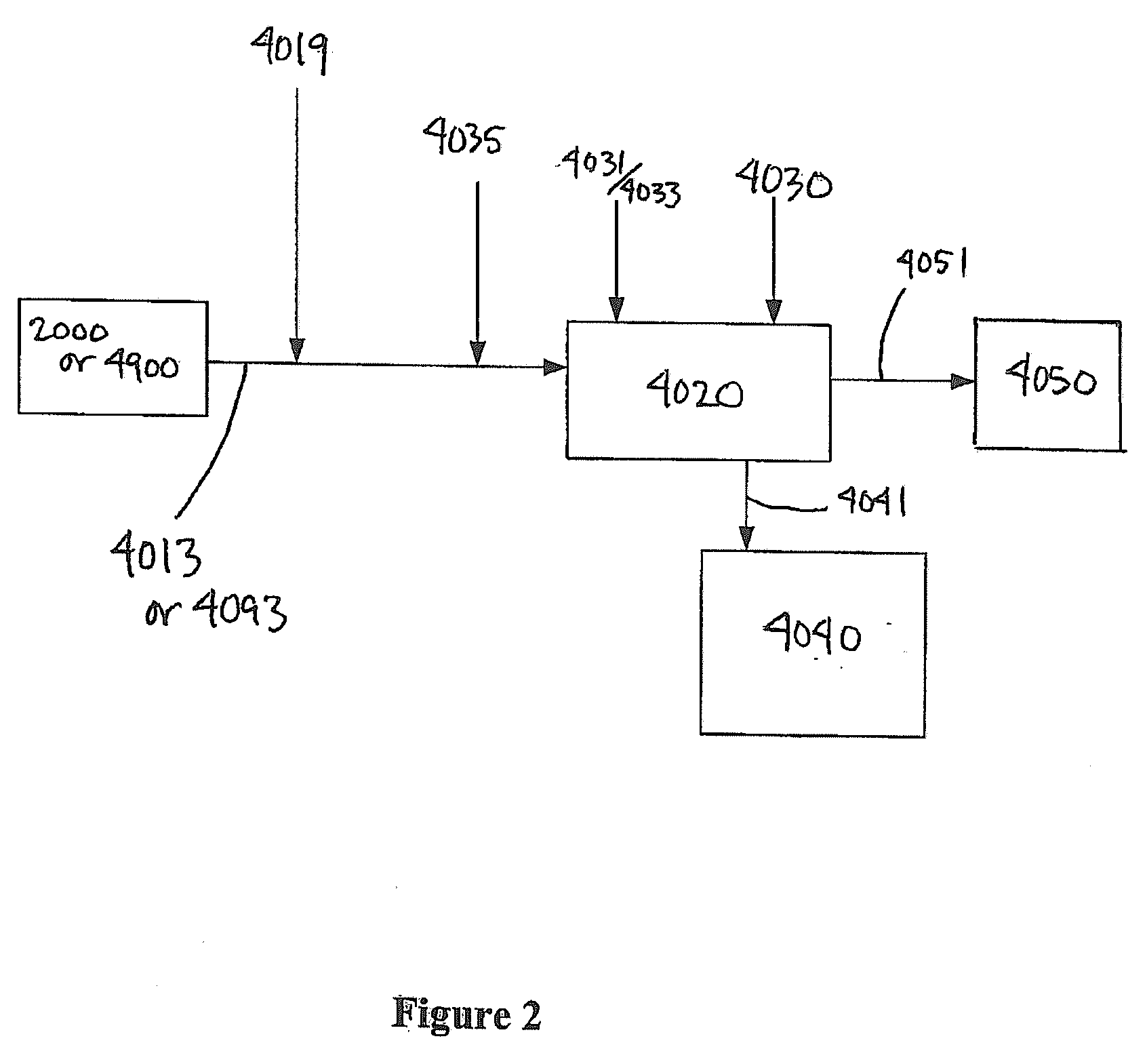

[0176]The present example is to provide an exemplary embodiment of the residue conditioning system of the present invention. Accordingly, the present example, as depicted in FIGS. 13 to 17, is provided to condition the residual matter produced in a typical gasification system during the gasification of carbonaceous feedstock. The sources of the residue to be conditioned are therefore the gasifier 2200 and the baghouse filter 6230 of a downstream gas conditioning subsystem of the gasification system. According to this example, the gasifier residue is removed from the gasifier 2200 by a first screw conveyor 2209 mounted at the end of the gasifier 2200. The first screw conveyor 2209 is provided as a toothed or serrated screw to break up agglomerated material. The residue is then conveyed via a gasifier residue screw conveyor 4218 to a main residue screw conveyor 4217. The baghouse residue is conveyed from the baghouse 6230 via a baghouse residue screw conveyor 4618 into the main residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com