Coke inhibitor and application thereof in biomass power generation boiler

A technology for biomass power generation and coke inhibitor, which can be used in fuel additives, petroleum industry, fuels, etc., and can solve problems such as limiting boiler efficiency improvement, high water content, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Embodiment 1 (comparative example)

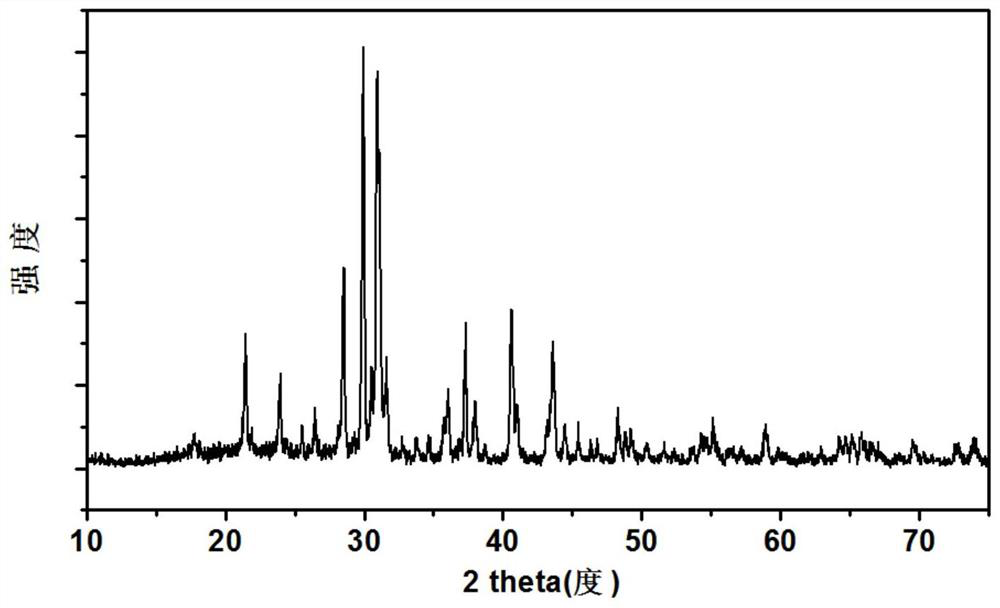

[0114] The biomass fuel that present embodiment adopts is the mixture (wherein paddy husk content is 70wt%, and chicken manure content is 30wt%) of wet chicken manure and paddy husk mixture without drying, and its average water content is 40.1wt% (because input every day The moisture content of the biomass will be different due to the influence of climate and transportation factors, so it is represented by the range); the biomass fuel is applied to the chicken manure circulating fluidized bed power generation boiler for incineration and power generation. After long-term operation monitoring, the results show that The continuous normal operation period of the boiler system is 30 days. The ash accumulation and coking on the superheater is serious. The ash deposits in the superheater are mainly composed of KCl, potassium sulfate and calcium chloride alkali phosphate, and the ash deposits at the bottom of the furnace are less, accounting...

Embodiment 2

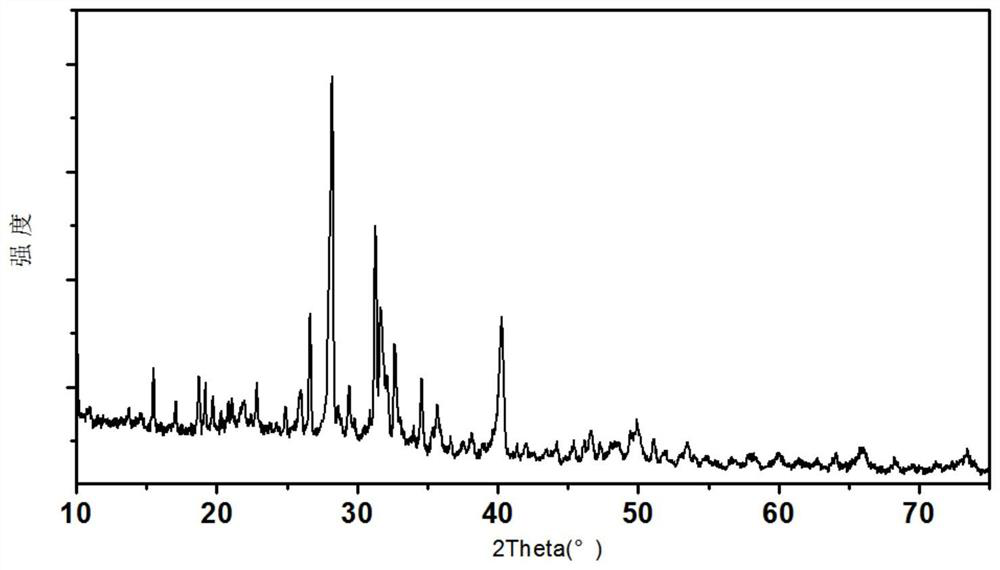

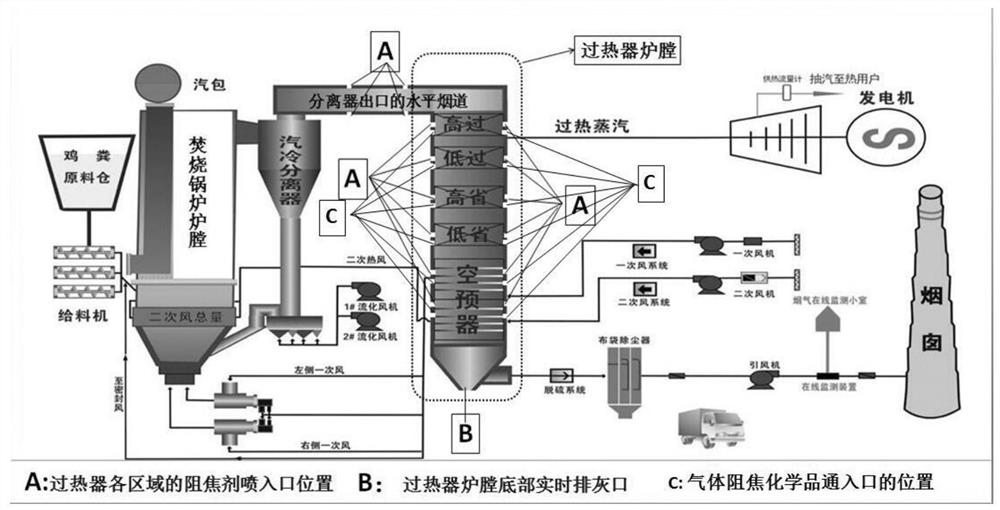

[0117] The difference between this embodiment and Example 1 is that the biomass fuel is added with a coke inhibitor, which includes coke inhibitor chemicals and quartz sand, and the particle size of the quartz sand is 0.2-0.8mm; the components of the coke inhibitor chemicals It is: calcium sulfate; in this embodiment, the anti-coking chemical accounts for 0.25% of the mass proportion of the raw material fuel, and the weight fraction of quartz sand relative to the raw material fuel is 0.05-0.025wt%. After the coke-resisting chemical with the above ratio is crushed until the maximum particle size is less than 0.8mm, it is evenly mixed with biomass fuel and sent to the power generation boiler for combustion; after the boiler starts normal operation, the quartz sand is simultaneously released from the biomass boiler separator The openings on both sides of the horizontal flue at the exit, the openings on both sides of the high temperature superheater area, the openings on both sides...

Embodiment 3

[0120]The difference between this embodiment and Example 1 is that the biomass fuel is added with a coke retarder, which includes a coke retarder chemical and quartz sand, and the quartz sand is 26 to 13wt% (quartz) relative to the weight of the entire coke retarder. The content of sand in the anti-coking agent changes dynamically every day), and the particle size of quartz sand is 0.2-0.8mm; the components and molar ratio of anti-coking chemicals are:

[0121] Calcium sulfate: 16 parts;

[0122] Calcium oxide: 63 parts;

[0123] Magnesium phosphate: 21 parts (based on the molar amount of phosphorus element);

[0124] Quartz sand: 26wt% ~ 13wt%

[0125] After crushing the above-mentioned anti-coking chemicals to a maximum particle size of less than 0.8mm, they are evenly mixed with quartz sand and biomass fuel and then sent to the incineration furnace of the power generation boiler for combustion; the amount of quartz sand in the coking inhibitor Decrease day by day with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com