Preparation of manganese phthalocyanine-modified horn-like carbon-based catalyst and electroreduction of CO 2 method

A technology of carbon-based catalysts and manganese phthalocyanine, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve complex and diverse coordination structures and low Faradaic efficiency , low metal loading rate and other issues, to achieve the effect of promoting efficient reduction reaction, high specific surface area, and promoting conversion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

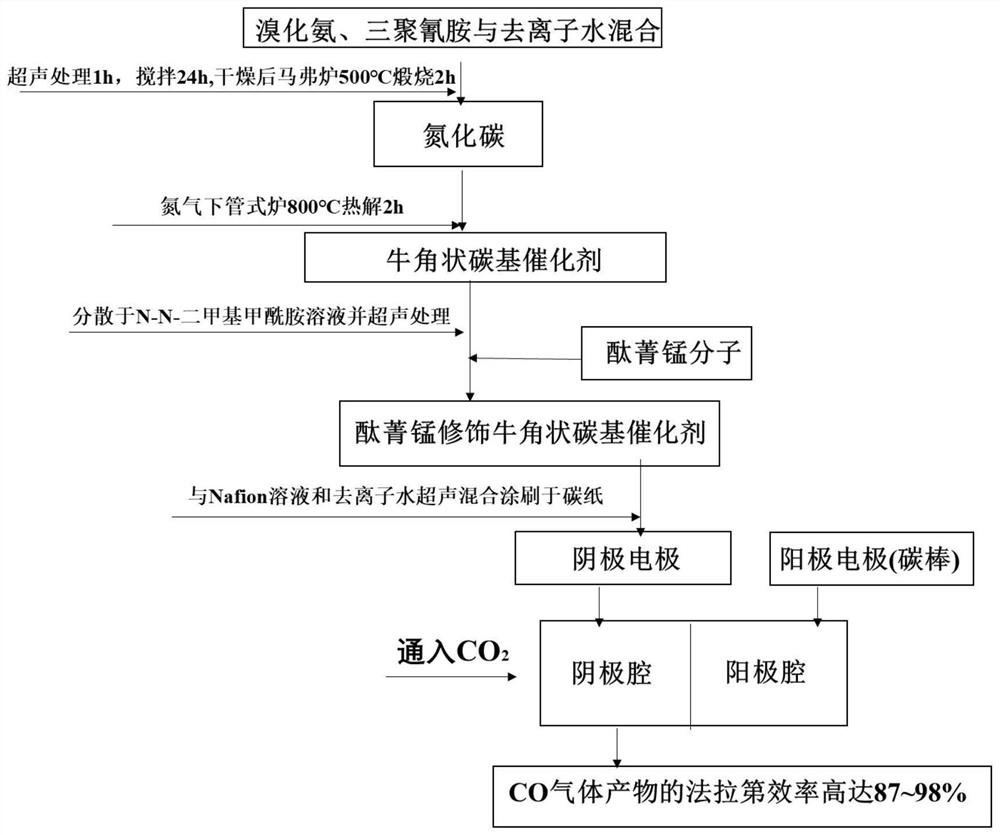

[0034] Take 23.3g of ammonium bromide and 1g of melamine, add 30mL of deionized water, ultrasonicate for 1h, stir for 24h, and then dry in a vacuum oven at 100°C for 8h to obtain a mixture. Take this mixture and place it in a crucible, put the crucible into a muffle furnace at room temperature, control the heating rate to 1.8°C / min, raise the temperature to 500°C, and then calcine at a constant temperature for 2 hours to obtain carbon nitride. Then put the carbon nitride into the tube furnace and feed nitrogen gas, control the heating rate of the tube furnace to 5°C / min, heat it to 600°C and then pyrolyze it at a constant temperature for 2 hours, and centrifuge the pyrolysis product three times with deionized water, Then place it in a vacuum oven at 60°C and dry to obtain a horn-shaped carbon-based catalyst. Take 0.6g of horn-like carbon-based catalyst, disperse it in 200mL of N-N-dimethylformamide solution, after ultrasonic treatment for 30min, add 50mg of manganese phthalocy...

Embodiment 2

[0038] Take 23.3g of ammonium bromide and 1g of melamine, add 30mL of deionized water, ultrasonicate for 1h, stir for 24h, and then dry in a vacuum oven at 100°C for 8h to obtain a mixture. Take this mixture and place it in a crucible, put the crucible into a muffle furnace at room temperature, control the heating rate to 1.8°C / min, raise the temperature to 500°C, and then calcine at a constant temperature for 2 hours to obtain carbon nitride. Then put the carbon nitride into the tube furnace and feed nitrogen, control the heating rate of the tube furnace to 5°C / min, heat to 700°C and then pyrolyze at a constant temperature for 2 hours, and centrifuge the pyrolysis product three times with deionized water, Then place it in a vacuum oven at 60°C and dry to obtain a horn-shaped carbon-based catalyst. Take 0.6g of horn-like carbon-based catalyst, disperse it in 200mL of N-N-dimethylformamide solution, after ultrasonic treatment for 30min, add 60mg of manganese phthalocyanine mole...

Embodiment 3

[0042] Take 23.3g of ammonium bromide and 1g of melamine, add 30mL of deionized water, ultrasonicate for 1h, stir for 24h, and then dry in a vacuum oven at 100°C for 8h to obtain a mixture. Take this mixture and place it in a crucible, put the crucible into a muffle furnace at room temperature, control the heating rate to 1.8°C / min, raise the temperature to 500°C, and then calcine at a constant temperature for 2 hours to obtain carbon nitride. Then put the carbon nitride into the tube furnace and feed nitrogen gas, control the heating rate of the tube furnace to 5°C / min, heat to 800°C and then pyrolyze at a constant temperature for 2 hours, and centrifuge the pyrolysis product three times with deionized water, Then place it in a vacuum oven at 60°C and dry to obtain a horn-shaped carbon-based catalyst. Take 0.6g of horn-shaped carbon-based catalyst, disperse it in 200mL of N-N-dimethylformamide solution, after ultrasonic treatment for 30min, add 70mg of manganese phthalocyanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com