Combined technical method of basic metal carbon sequestration and coal hydrogen production catalysis in critical fluid reaction system

A technology of fluid reaction and continuous use technology, applied in chemical instruments and methods, non-metallic elements, hydrogen, etc., can solve the problems of inability to achieve continuous high-efficiency hydrogen production, and achieve the effect of promoting water-gas conversion reaction and improving decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

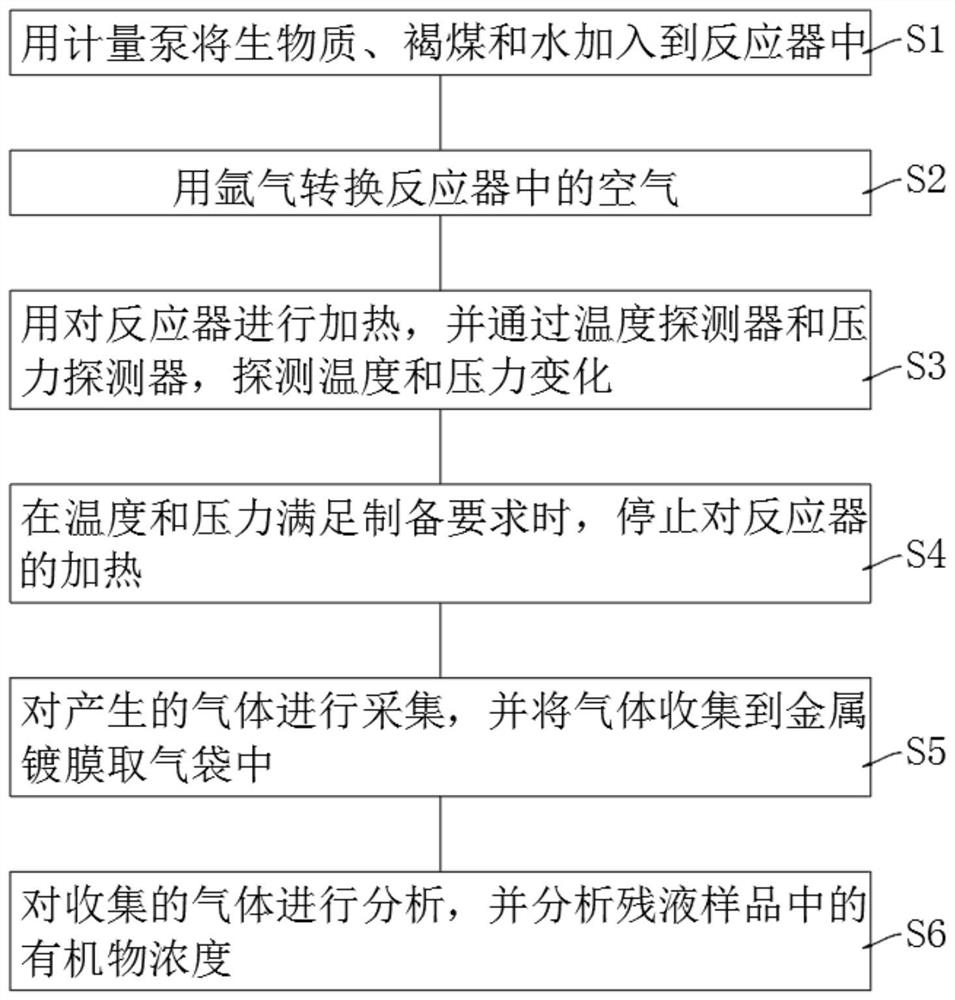

[0042] Please refer to figure 1 as shown, figure 1 It is a flow chart of the technical method for the combined use of base metal carbon sequestration and coal-to-hydrogen catalysis in the critical fluid reaction system, and the technical method for the combined use of base metal carbon sequestration and coal-to-hydrogen catalysis in the critical fluid reaction system includes the following steps:

[0043] Step 1: Add biomass, lignite and water into the reactor with a metering pump.

[0044] Step 2, changing the air in the reactor with argon.

[0045] Step 3: Heating the reactor, and detecting changes in temperature and pressure through a temperature detector and a pressure detector.

[0046] Step 4. Stop heating the reactor when the temperature and pressure meet the preparation requirements.

[0047] Step 5: Collect the generated gas, and collect the gas into the metal-coated gas-taking bag.

[0048] Step 6: Analyzing the collected gas and analyzing the concentration of orga...

Embodiment 2

[0059] The technology and method for the combined use of base metal carbon sequestration and coal-to-hydrogen catalysis in the critical fluid reaction system provided in this example are roughly the same as those in Example 1, with the main differences being:

[0060] Potassium salt is kainite.

[0061] The temperature is 500°C, and the reaction pressure is 30MPa;

[0062] Use a metering pump to inject water for flushing, and the flushing time is 11 minutes.

Embodiment 3

[0064] The technology and method for the combined use of base metal carbon sequestration and coal-to-hydrogen catalysis in the critical fluid reaction system provided in this example are roughly the same as those in Example 1, with the main differences being:

[0065] The potassium salt is potassium chloride.

[0066] The temperature is 510°C, and the reaction pressure is 30MPa;

[0067] Use a metering pump to inject water for flushing, and the flushing time is 12 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com