Multi-channel stepped electric gas control valve

A gas adjustment, step-type technology, applied in the direction of multi-way valves, fuel supply adjustment, valve details, etc., can solve the problem of gas channels that cannot be used for ignition or large fires, where the relative position cannot be accurately determined, and the ignition cannot be adjusted independently, etc. problem, to achieve the effect of accurate system closed-loop adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

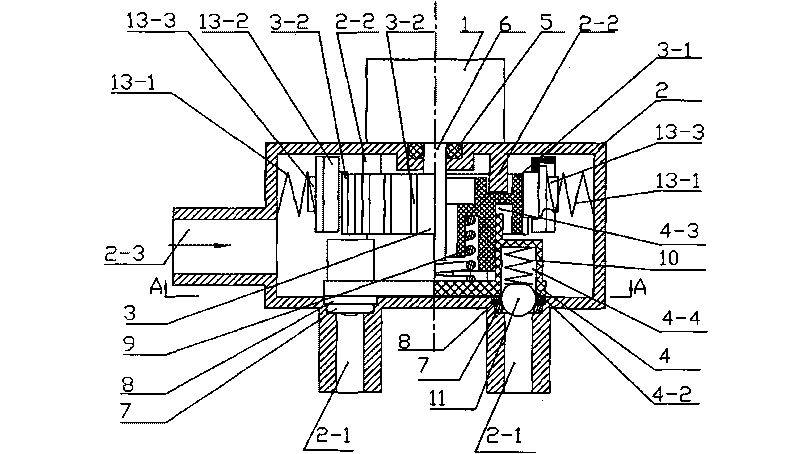

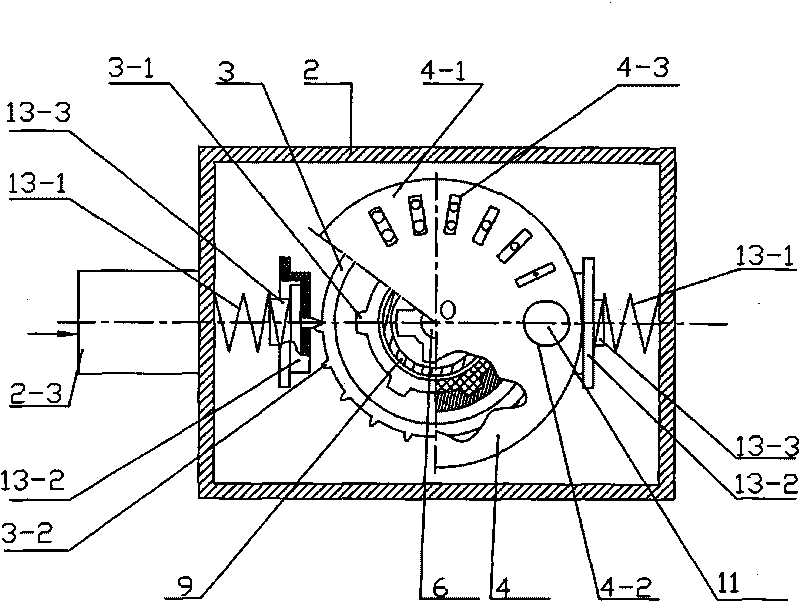

[0030] see figure 1 , figure 2 As shown, a mechanical multi-channel step-type electric gas regulating valve is composed of a geared motor 1, a valve housing 2, a positioner 3, an air distributor 4, and a positioner rotation angle detection mechanism. A geared motor 1 is installed on the outer side of the valve housing 2, a housing wall. The drive shaft 6 of the geared motor 1 extends into the valve body 2 and is sealed with the housing wall through an O-ring 5. The valve housing 2 perpendicular to the drive shaft 6 The other housing wall is provided with two air outlets 2-1, and the valve housing 2 is also provided with an air inlet 2-3. A cylindrical locator 3 is installed on the drive shaft 6 , and a group of vertical and parallel protruding teeth 3 - 2 are arranged on the outer circumference of the locator 3 as the positioning nodes of the locator 3 . The circular air distributor 4 is slidingly connected with the positioner 3 through its own spline 4-3 and the spline 3-1...

Embodiment 2

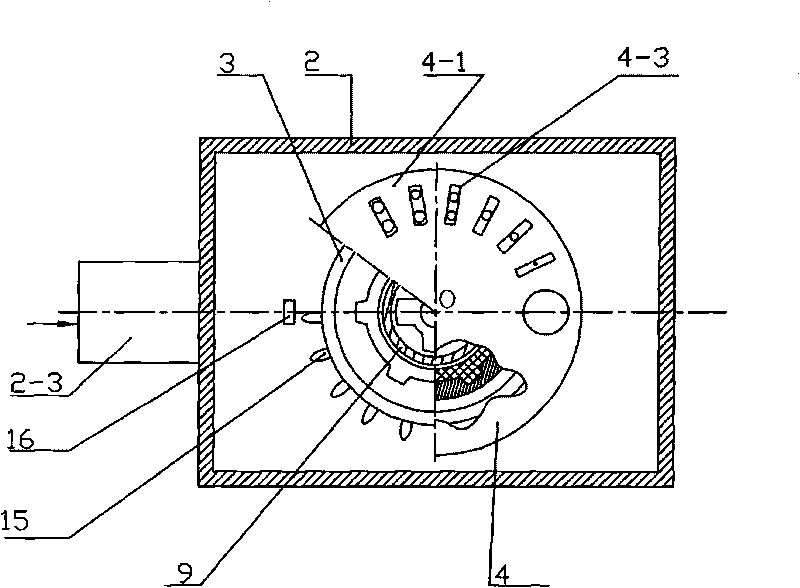

[0032] see image 3 As shown, this example is a magnetoelectric multi-channel step-type electric gas control valve, that is, the positioner rotation angle detection mechanism adopts a magnetoelectric structure, and other structures are the same as in Embodiment 1. The rotation angle detection mechanism of the magnetoelectric positioner consists of a row of permanent magnet blocks 15 installed at the same horizontal position on the outer circumference of the positioner 3 and a Hall element fixed on the inner wall of the valve housing 2 opposite to the row of permanent magnet blocks 15 16 compositions. When the locator 3 rotates, the Hall element will send the position signal of the locator 3 to the control circuit to control the output of the gas under the action of the permanent magnet blocks 15 .

Embodiment 3

[0034] see Figure 4 As shown, this example is a photoelectric multi-channel step-type electric gas regulating valve, that is, the positioner rotation angle detection mechanism adopts a photoelectric structure, and other structures are the same as in Embodiment 1. The photoelectric positioner rotation angle detection mechanism consists of a row of through holes 17 located at the same horizontal position on the outer circumference of the positioner 3, and light-emitting diodes 18 and photoelectric receivers that are respectively located on both sides of the row of through holes 17 and fixed on the valve housing 2. Tube 19 is composed. When the positioner 3 rotates, the light emitted by the light-emitting diode 18 passes through the through hole 17 and is received by the photoelectric receiving tube 19 and outputs the position signal of the positioner 3 to the control circuit at this time, so as to realize the control of the gas output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com