Method for preparing methylal by combining reaction rectification and extraction

A technology of dimethoxymethane and reactive distillation, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of long cycle, many procedures, high energy consumption, etc., and achieve purity and yield High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

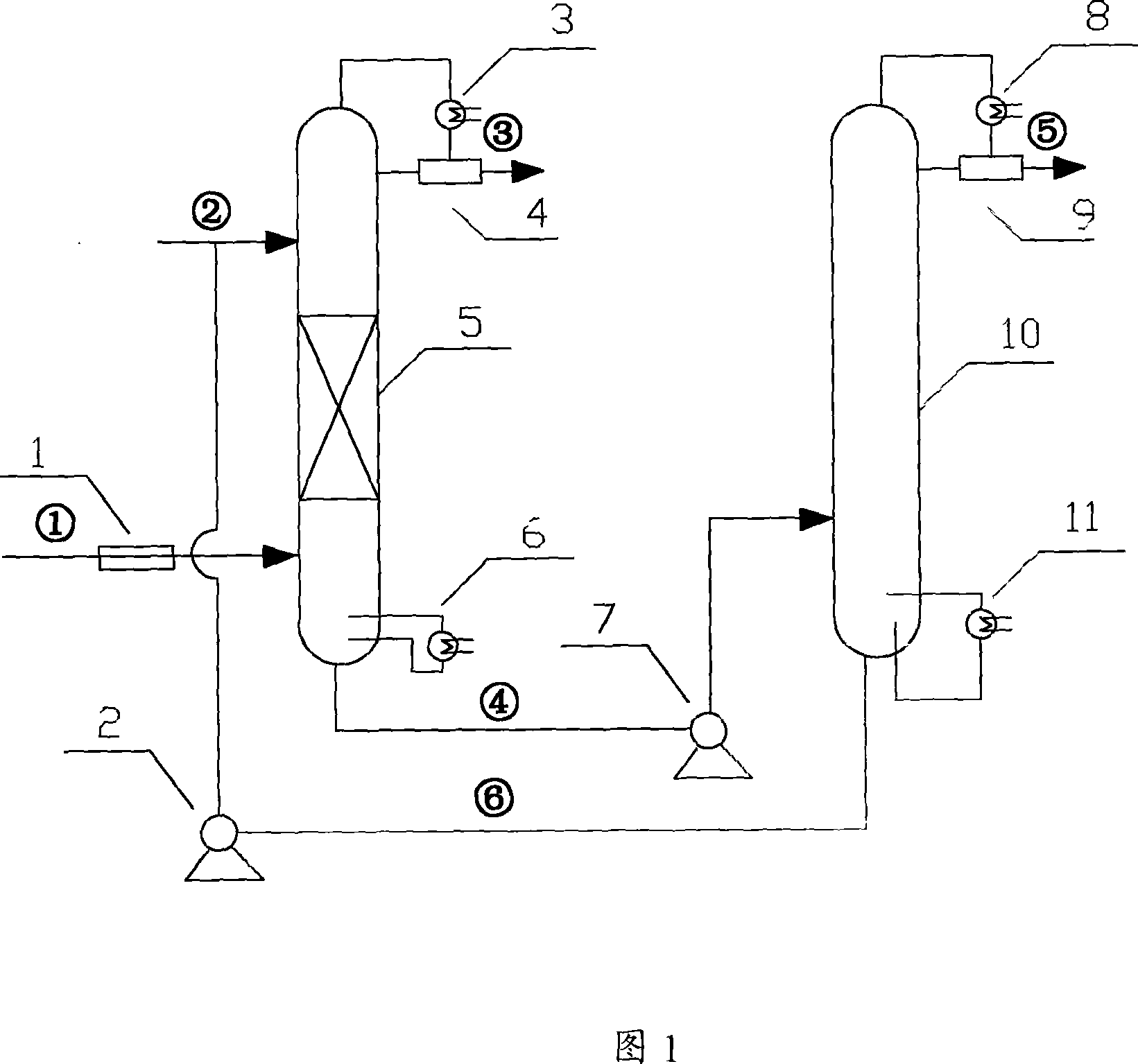

[0015] Embodiment 1, with reference to Fig. 1: preparation raw material methanol, formaldehyde solution (containing formaldehyde 37%~40%) mass ratio is 0.9: 1; The mass ratio of extraction agent ethylene glycol and raw material is 1.2: 1; Catalyst p-toluenesulfonic acid mass ratio 5% of the raw material. Raw materials (methanol, formaldehyde) and reagents (ethylene glycol and p-toluenesulfonic acid) are fed into the tower at a mass flow rate of 15mL / min, and the bottom of the tower is discharged at the same flow rate into the solvent recovery tower. The DMM content in the obtained product reaches more than 99.5%, and the yield reaches more than 85%. The specific operating conditions are shown in Table 1, and the separation results are shown in Table 2.

[0016] The steps are: the raw material ① (methanol and formaldehyde solution) enters the extraction reaction rectification tower through a metering pump through the feed port, and the feed port of the raw material is set at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com