High concentration methylal pressure distillation process and preparation device thereof

A technology of pressurized rectification and preparation device, which is applied in the production field of methylal and can solve the problems of not being able to obtain high-concentration products and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

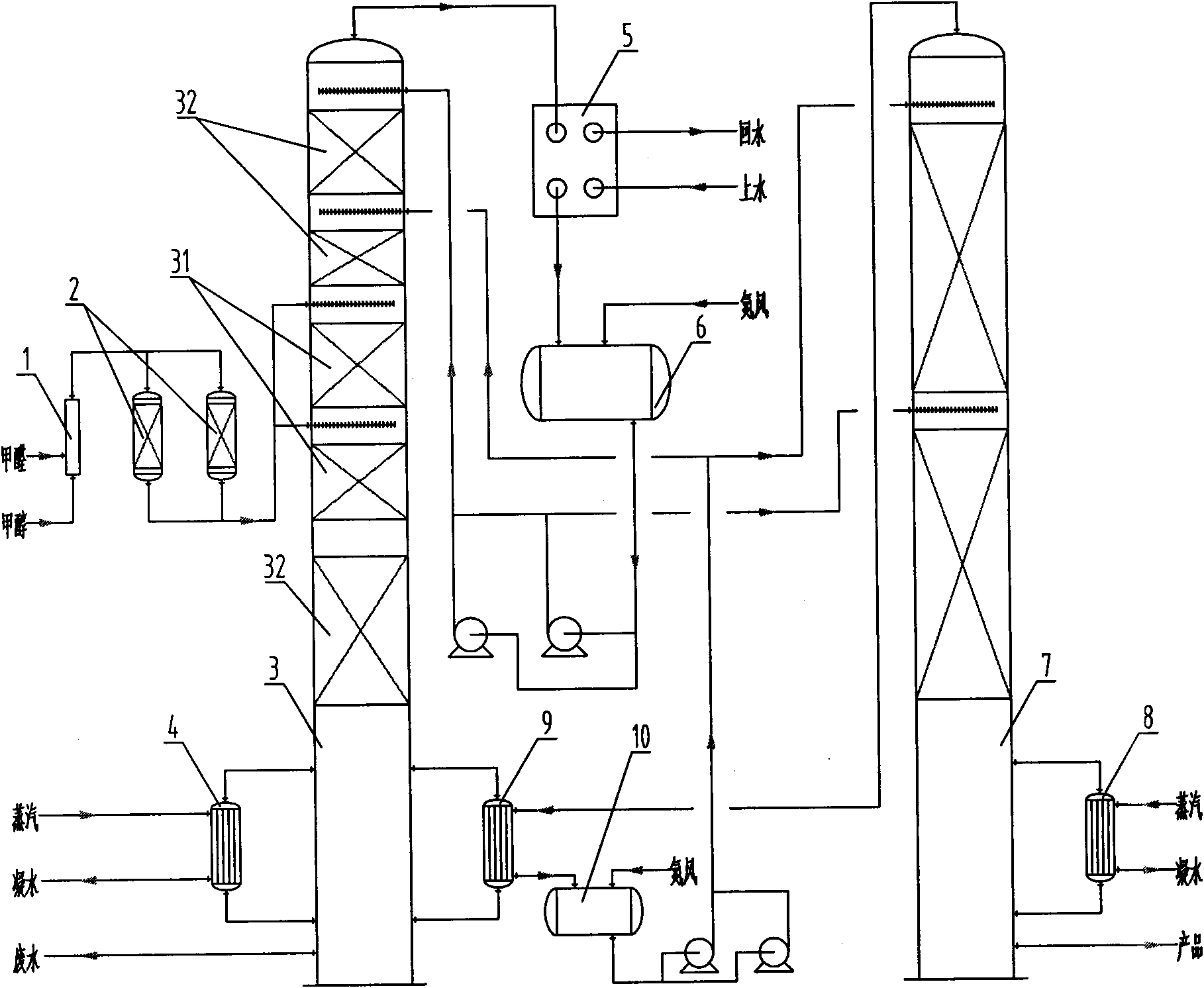

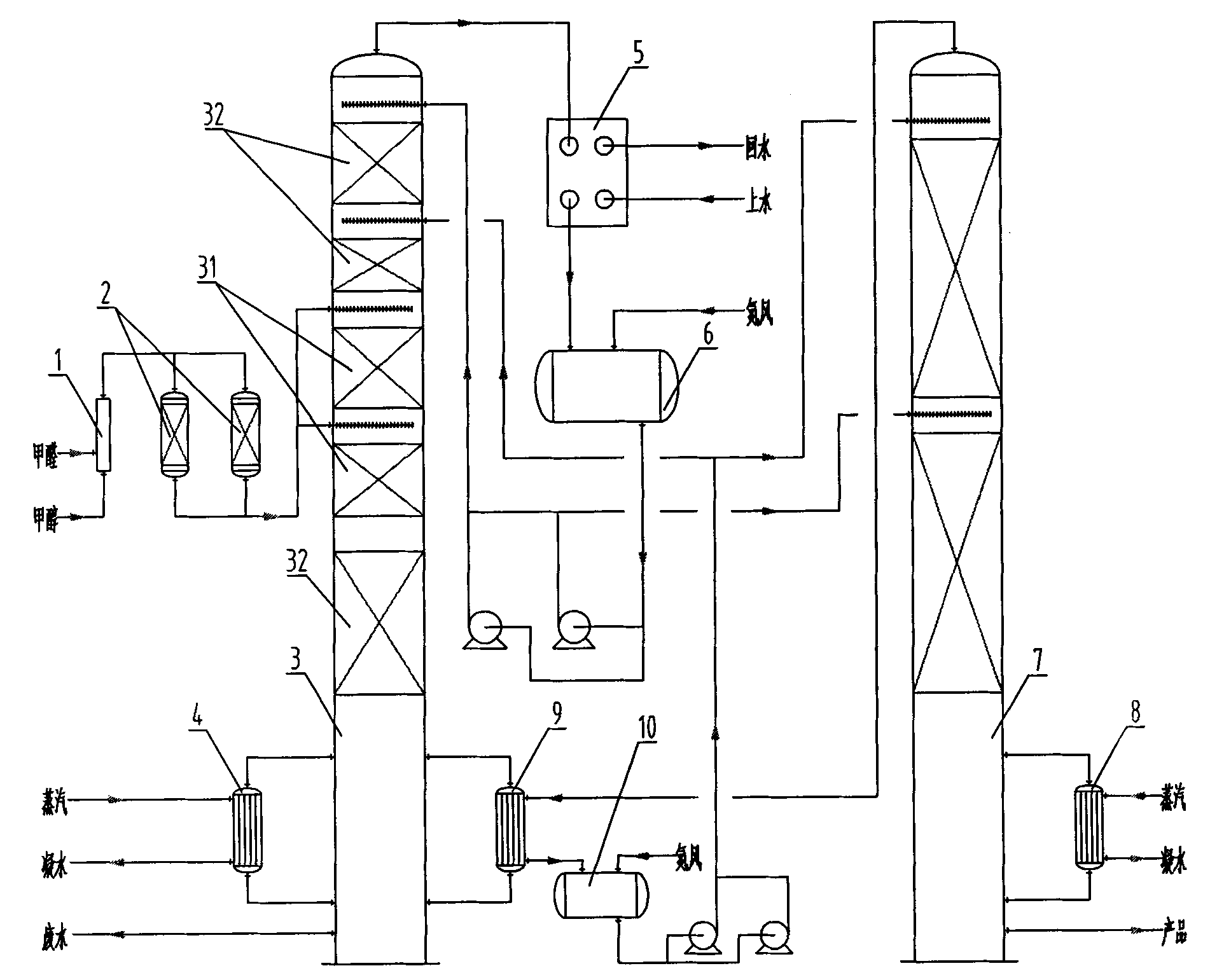

[0017] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0018] High Concentration Methylal Pressurized Distillation Process

[0019] a. Methanol and formaldehyde solutions are fully mixed in a ratio of 1.2:1, and the mixed solution is subjected to a liquid phase reaction, and the reaction temperature is controlled between 45°C and 85°C, and a mixed solution containing methylal is generated after the reaction;

[0020] b. The mixed liquid is heated to form a gas, and the gas forms a balanced gas-liquid two-phase through the action of the screen filler. The liquid is waste water containing formaldehyde, and the gas is an azeotrope of formaldehyde and methylal.

[0021] C. The azeotrope gas of formaldehyde and methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com