Method for synthesizing methyl acrylate by means of filling catalysts in sections

A methyl acrylate and catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, catalyst activation/preparation, etc., can solve problems such as low reaction conversion rate, and achieve the effects of improving conversion rate, improving reaction, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this example, 0.5g of lactic acid was dissolved in 5ml of hot water, and 0.5g of NH 4 VO 3 Add it into the lactic acid solution to make a vanadyl lactate solution, add 1.3g of phosphoric acid to make an impregnation solution, and then dissolve the chromatographic silica gel in 20ml of water. The two suspensions were stirred for 2 h to mix well. Evaporate the impregnating solution to dryness in a water bath, and dry it at 100°C until it becomes powdery. Then place it in a muffle furnace and burn at 200°C for 2 hours, at 300°C for 1 hour, and at 450°C for 3 hours to prepare the phosphorus vanadium catalyst. Under normal pressure, using the prepared catalyst with a V / P ratio of 1:2.5, the molar ratio of methyl acetate / formal is 1.6:1, and the feed space velocity is 3h -1 Methyl acrylate was reacted under certain conditions, the conversion rate of methylal was 15%, the selectivity of methyl acrylate was 72%, and the yield of methyl acrylate was 10.8%.

Embodiment 2

[0026] In this example, 35 ml of tetraethyl orthosilicate and 20 ml of absolute ethanol were stirred and heated to 60° C., and nitric acid was added dropwise to adjust the pH value to 3-4 to obtain a silica sol. 2g of Sb 2 o 3 Dissolve in 30ml of water, stir and add 5ml of triethanolamine as a stabilizer, then add 5ml of H 2 o 2 Produced Sb 2 o 5 Sol. Mix the silica sol and antimony gel and stir vigorously for 1 hour, adjust the pH value to 10 to prepare a mixed gel, add ammonium nitrate to dissolve the sol, raise the temperature to reflux, and react for 6 hours. Take out and dry in an oven at 80°C. Then put it in a muffle furnace to program the temperature to burn to obtain a white mixed gel, grind the mixed gel into 20-40 mesh, and impregnate 0.2g of CsNO 3 , and fired at 550°C for 3 hours to obtain Cs-Sb 2 o 5 / SiO 2 . Under the action of this catalyst, the methyl acetate / formaldehyde / molar ratio is 3:1, and the feed space velocity is 3h -1 Methyl acrylate was r...

Embodiment 3

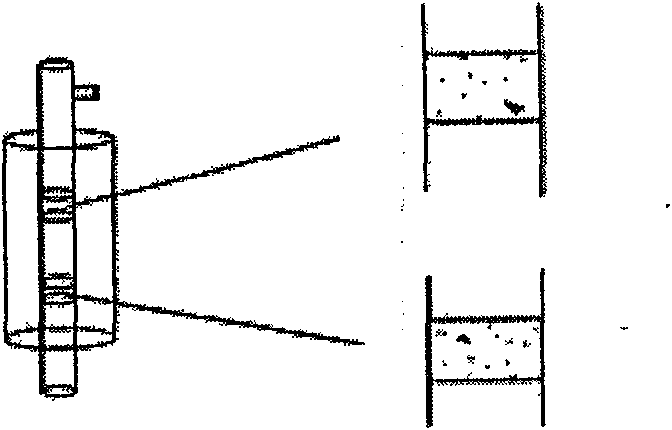

[0028] The basic steps of this example are the same as those in Example 1, except that the two catalysts are loaded from top to bottom, and the phosphorus and vanadium are loaded in the third section, and the Cs-Sb 2 o 5 / SiO 2 The catalyst is loaded in the seventh section, the furnace temperature is set at 380°C, the molar ratio of methyl acetate / methylal is 1.6:1, and the feed space velocity is 3h -1 Methyl acrylate was reacted under the above conditions, the conversion rate of methylal at this time was 49.85%, the selectivity of methyl acrylate was 47.33%, and the yield of methyl acrylate was 23.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com