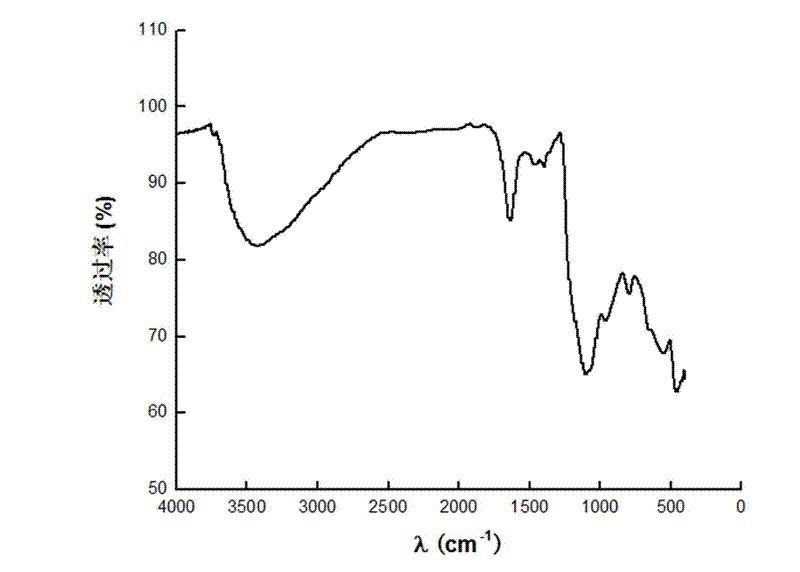

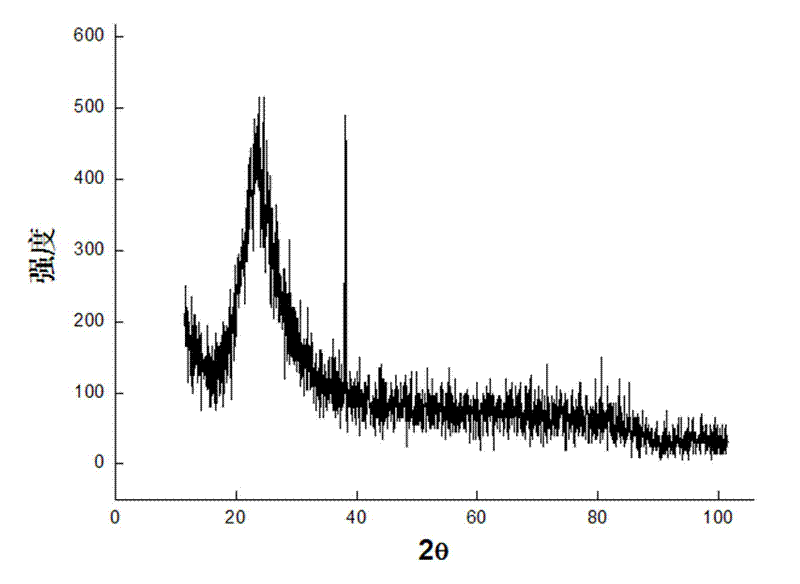

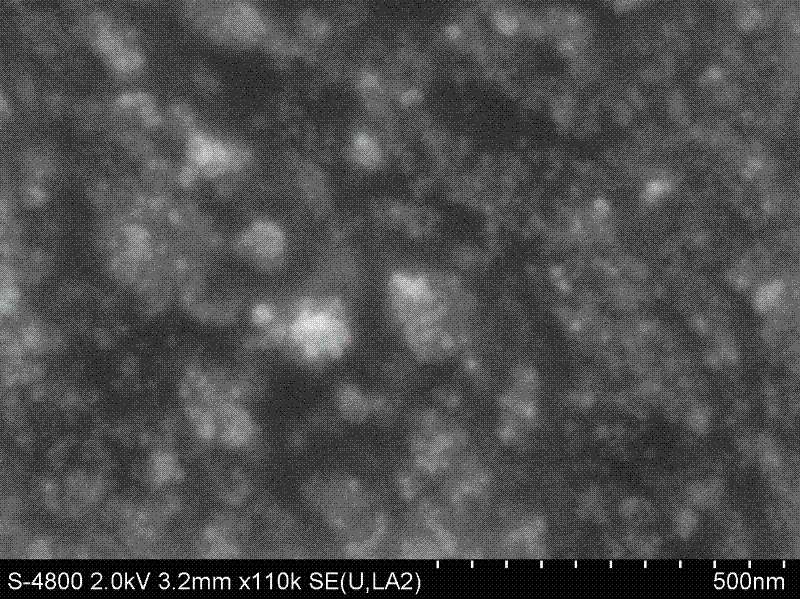

Preparation method and use of hydrophilic automatically-cleaning coating with photocatalytic activity

A photocatalytic active and hydrophilic technology, applied in coatings, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of difficult industrial application, short hydrophilicity retention period of coatings, etc., and achieve the effect of reducing cleaning cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of silica sol: Accurately measure 50ml of absolute ethanol and place it in a 200ml beaker. o In the water bath of C, adjust the pH=2.0 with hydrochloric acid with a mass concentration of 36-38%, and stir for 30 min (at a speed of 3000 rad / min); add 7 ml of tetraethyl orthosilicate, and stir for 10 min; add 5.0 ml of double distilled water, Stirring was continued for 30 min to obtain a colorless and transparent silica sol.

[0034] ② Preparation of titanium sol: Accurately measure 100ml of absolute ethanol and place it in a 500ml beaker. o In the water bath of C, adjust the pH=2.0 with hydrochloric acid with a mass concentration of 36-38%, and stir for 30 min (at a speed of 3000 rad / min); add 2 ml of butyl titanate, and stir for 10 min; add 10 ml of twice distilled water, and continue stirring After 30 min, a colorless and transparent titanium sol was obtained.

[0035] ③ Preparation of silicon-titanium composite sol: Slowly add 50ml of silica sol into ...

Embodiment 2

[0038] (1) Preparation of silica sol: Accurately measure 50ml of absolute ethanol and place it in a 200ml beaker. o In the water bath of C, adjust the pH=2.5 with hydrochloric acid with a mass concentration of 36-38%, and stir for 30 min (stirring speed 2500 rad / min); add 3.5ml of tetraethyl orthosilicate under stirring, stir for 30min; double distilled water, and continued to stir for 30 min to obtain a colorless and transparent silica sol.

[0039] (2) Preparation of titanium sol: Accurately measure 100ml of absolute ethanol and place it in a 500ml beaker. o In the water bath of C, adjust the pH=2.5 with hydrochloric acid with a mass concentration of 36-38%, and stir for 20 min (at a speed of 2500 rad / min); add 2 ml of butyl titanate under stirring, and stir for 10 min; add 8.0 ml of twice distilled water , and continued stirring for 30 min to obtain a colorless and transparent titanium sol.

[0040] (3) Preparation of paint: Slowly add 50 ml of silica sol into 100 ml of t...

Embodiment 3

[0043] (1) Preparation of silica sol: Accurately measure 50ml of absolute ethanol in a 200ml beaker, o In the water bath of C, adjust the pH=3.5 with hydrochloric acid with a mass concentration of 36-38%, and stir for 10 min (stirring speed is 2000 rad / min); ml of double-distilled water, and continued to stir for 30 min to obtain a colorless and transparent silica sol.

[0044] (2) Preparation of titanium sol: Accurately measure 100ml of absolute ethanol and place it in a 500ml beaker. o In the water bath of C, adjust the pH=3.5 with hydrochloric acid with a mass concentration of 36-38%, and stir for 30 min (stirring speed is 2000rad / min); add 3.0ml of butyl titanate under stirring, and stir for 10min; distilled water and continued to stir for 30 min to obtain a colorless and transparent titanium sol.

[0045] (3) Preparation of paint: Slowly add 50ml of silica sol into 100ml of titanium sol, and continue stirring for 1.5h to obtain a colorless and transparent silica-titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com