Inorganic fireproof heat-insulating material and preparation method thereof

A technology of fireproof heat preservation and inorganic gel materials, which is applied in the field of fireproof heat preservation materials and their preparation, which can solve the problems of easy falling, difficult construction, poor weather resistance, etc., and achieve good heat preservation performance, mature preparation method, and good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

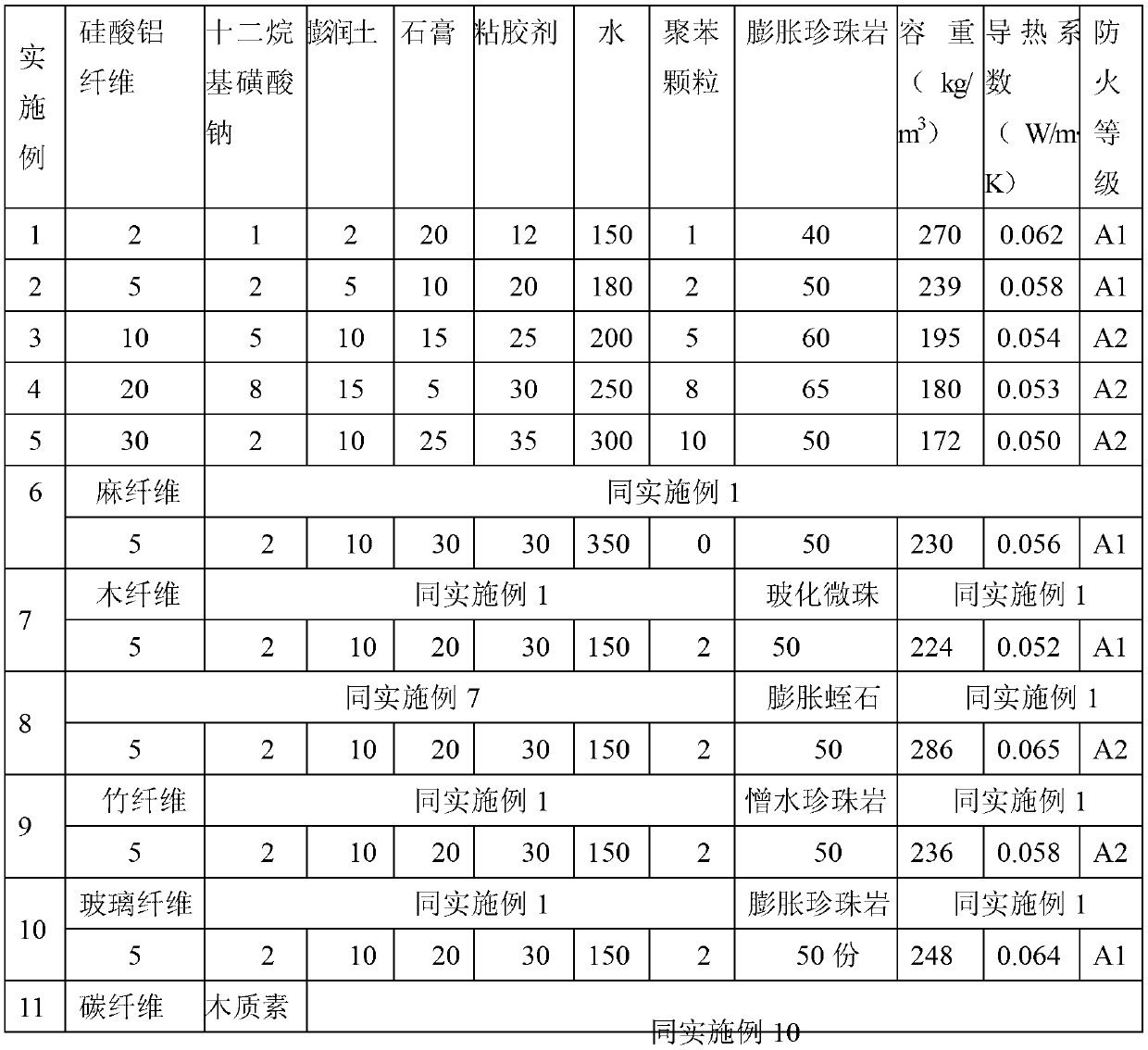

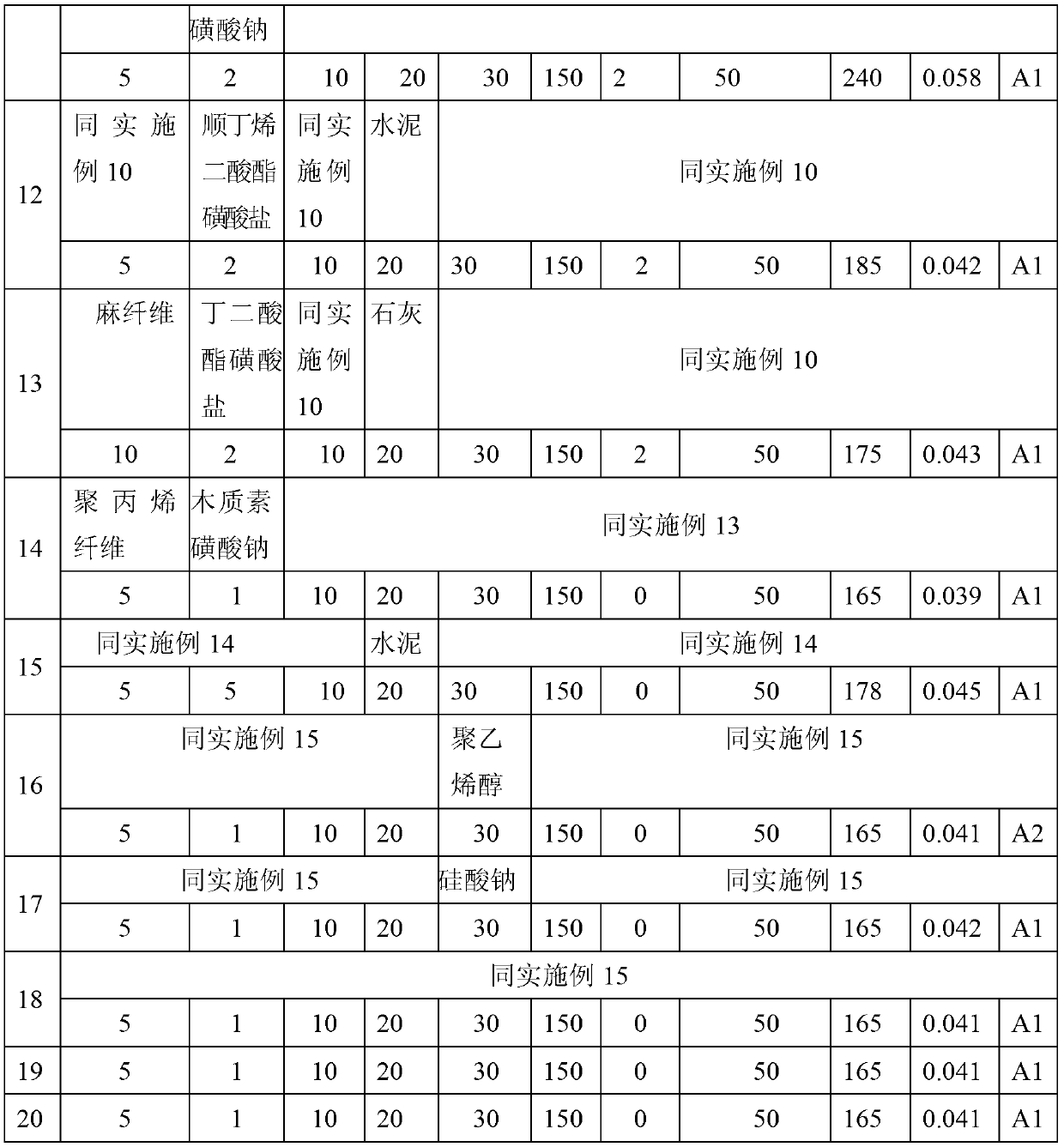

[0021] The composition of the inorganic fireproof and thermal insulation material of the present invention is to add a certain amount of reinforcing fiber, inorganic gel material and adhesive to the traditional perlite formula, add a certain amount of interface agent before stirring, and add a certain amount of expansion before adding light aggregate Polystyrene particles.

[0022] The components and parts by weight of the inorganic fireproof and thermal insulation material of the present invention are: 0.5-30 parts of reinforcing fiber; 40-65 parts of light aggregate; 2-15 parts of bentonite; 12-35 parts of adhesive; inorganic gel material 5-20 parts; interface agent 2-10 parts; expanded polystyrene particles 0-10 parts; water 200-260 parts.

[0023] The reinforcing fiber is one of glass fiber, aluminum silicate fiber, carbon fiber, polypropylene fiber, wood fiber, bamboo fiber and hemp fiber; preferably wood fiber and hemp fiber.

[0024] The lightweight aggregate is one or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com