4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and preparation method thereof

A technology of diaminophenoxy and epoxy adhesives, applied in the direction of online phenolic epoxy resin adhesives, adhesives, epoxy resin adhesives, etc., can solve the problem of high price, unfavorable large-scale popularization and application, polyetherimide Resin cost is high, to achieve the effect of convenient operation, good application prospect and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of component A

[0046] Combine 100 grams of N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenylmethane epoxy resin (epoxy value 0.8) with 23.1 grams (0.05 mol) 4,4'- The bis(2,4-diaminophenoxy)diphenylsulfone was put into the reaction kettle, heated to 50°C, stirred and reacted for 2 hours to obtain 123.1 g of a homogeneous and transparent copolymer, which was recorded as A1.

[0047] Combine 100 grams of N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenylmethane epoxy resin (epoxy value 0.8) with 18.5 grams (0.04 moles) of 4,4'- The bis(2,4-diaminophenoxy)diphenylsulfone was put into the reaction kettle, heated to 90°C, stirred for 0.5 hours, and 118.5 g of homogeneous and transparent copolymer was obtained, which was recorded as A2.

[0048] Combine 100 grams of 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester epoxy resin (epoxy value 0.85) with 21.7 grams (0.047 mole) 4,4'-bis(2,4 -Diaminophenoxy) diphenyl sulfone was put into the reaction kettle, heated to 60°C...

Embodiment 2

[0052] Preparation of component B

[0053] At room temperature, add 46.2 g (0.1 mol) 4,4'-bis(2,4-diaminophenoxy) diphenyl sulfone and 850 g N,N-dimethylacetamide into the reaction kettle, stir to dissolve completely Then, 104 grams (0.2 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride and 64.4 grams (0.2 moles) of 3,3',4,4' were added -Tetracarboxybenzophenone dianhydride, stirred and reacted for 0.5 hours to obtain 1064.6 g of homogeneous transparent solution, added 170 g of toluene, heated to reflux, and performed reflux water separation reaction. The temperature was 100°C and the reaction time was 2 hours. After the reaction is completed, part of the organic solvent is separated so that the solid content is in the range of 15%-30%, which is recorded as B1.

[0054] At room temperature, 46.2 g (0.1 mol) 4,4'-bis(2,4-diaminophenoxy) diphenyl sulfone, 310 g N,N-dimethylacetamide and 350 g N-methyl- 2-Pyrrolidone was added to the reaction kettle. After stirrin...

Embodiment 3

[0058] Preparation of 4,4'-bis(2,4-diaminophenoxy)diphenylsulfone type high temperature resistant epoxy adhesive

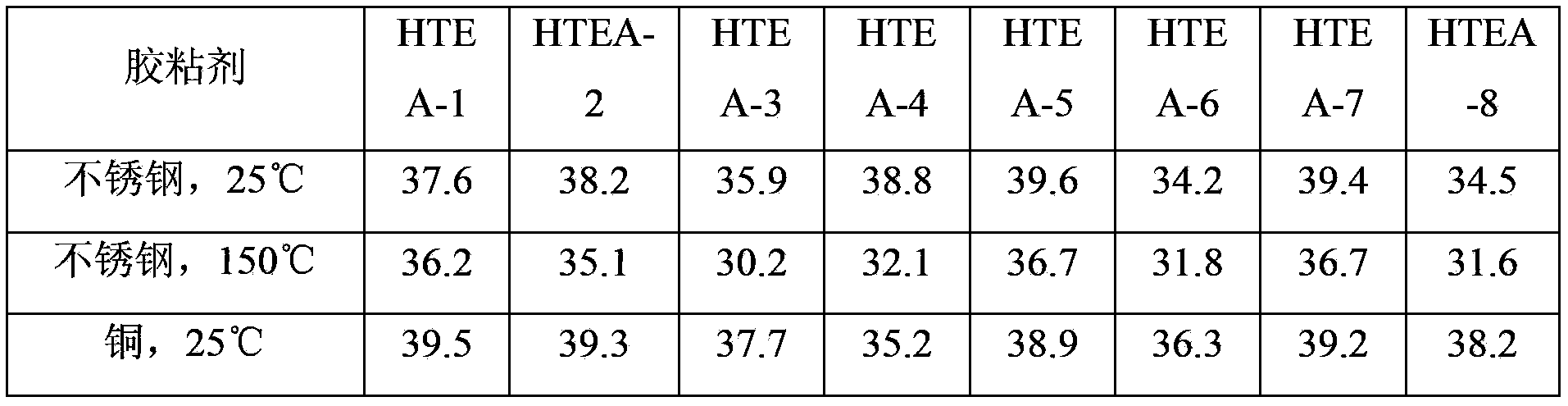

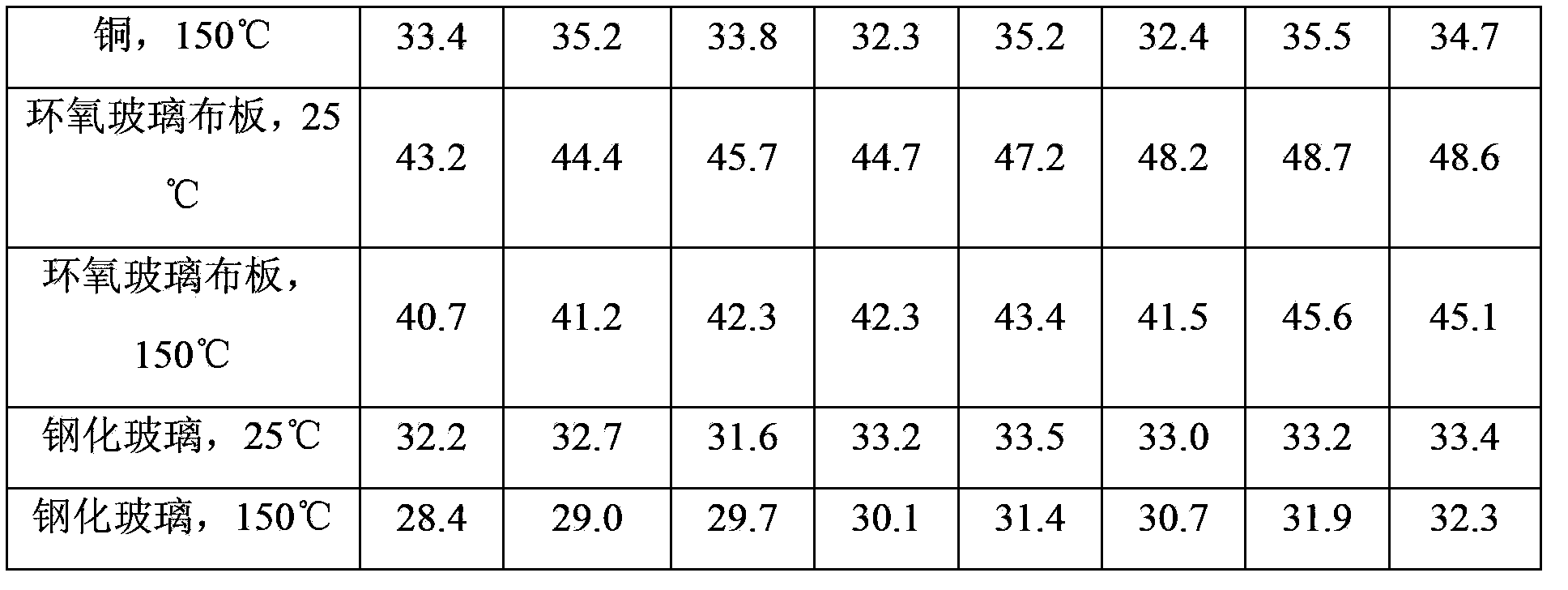

[0059] At room temperature, stir and mix components A and B at a mass ratio of 1:1-2 to obtain a series of 4,4'-bis(2,4-diaminophenoxy)diphenylsulfone type high temperature resistant Epoxy adhesive, denoted as HTEA-p, p is a natural number, the specific formula is shown in Table 1.

[0060] Table 14. Formula table of 4'-bis(2,4-diaminophenoxy)diphenylsulfone type high temperature epoxy adhesive unit: grams

[0061] Component

[0062] HTEA-8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com