A kind of dahtm type silicon-containing epoxy imide matrix resin and preparation method thereof

A technology of silicon epoxy imide matrix and epoxy resin, which is applied in the field of polymer matrix resin and its preparation, can solve problems such as unsatisfactory heat resistance, achieve good industrialization prospects, simple preparation process, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

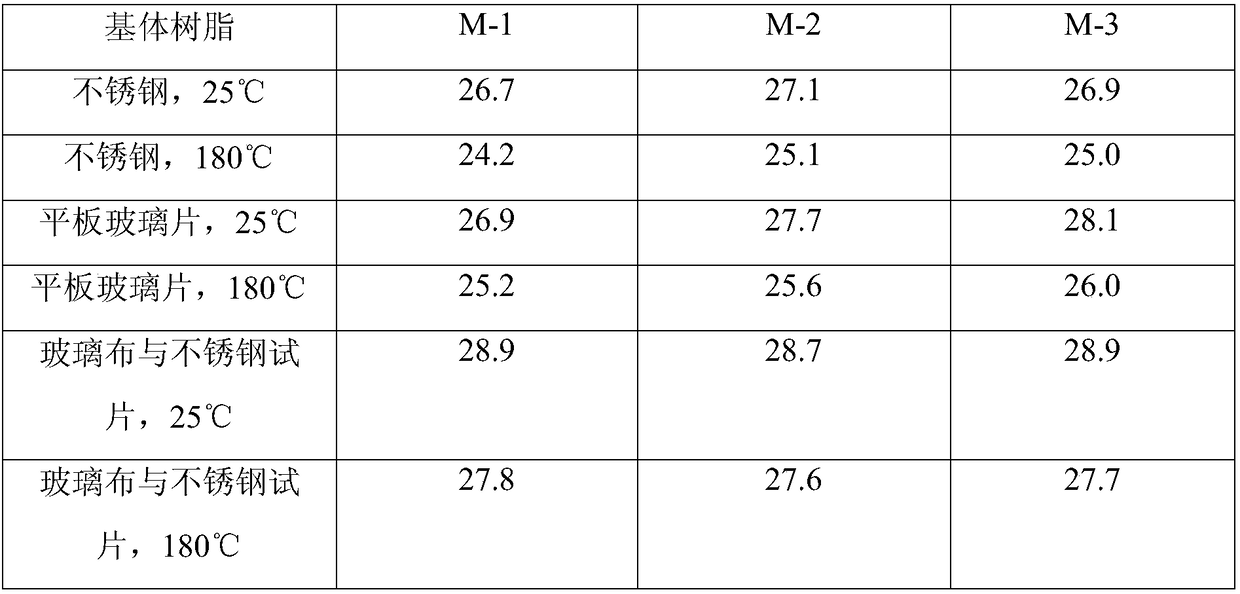

Examples

Embodiment 1

[0043] 73.2 grams (0.2 moles) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (BAHPFP, 366 g / mol), 735.0 grams of o-cresol, 52.0 grams (0.1 moles) of 2,2- Bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride (BPADA, 520g / mol) and 19.6 grams (0.2mol) of maleic anhydride (MA, 98g / mol) were placed in the reactor , feed nitrogen, stir, heat up to 80°C, add 3.8 grams of isoquinoline dropwise, heat to 100°C, stir and react for 5 hours, then cool to 60°C, pour the reactant into a precipitate containing 1500 grams of methanol Stir in the kettle at high speed to precipitate solid matter, filter, and vacuum-dry at 80°C for 10 hours to obtain 308.3 g of imide oligomer (theoretical yield: 314.0 g), with a yield of 98.2%, which is designated as BBMO-1.

Embodiment 2

[0045] 73.2 g (0.2 mol) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (BAHPFP, 366 g / mol), 1460 g of o-cresol, 52.0 g (0.1 mol) of 2,2- Bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride (BPADA, 520g / mol) and 19.6 grams (0.2mol) of maleic anhydride (MA, 98g / mol) were placed in the reactor , feed nitrogen, stir, heat up to 80°C, add 14.0 grams of isoquinoline dropwise, heat to 110°C, stir and react for 12 hours, cool to 60°C, pour the reactant into 2000 grams of ethanol and 920 grams of In the settling tank of ethylene glycol monomethyl ether, high-speed stirring, the solid matter was precipitated, filtered, and vacuum-dried at 80°C for 10 hours to obtain 313.4 grams of imide oligomers (theoretical yield: 314.0 grams), with a yield of 99.8%. Denoted as BBMO-2.

Embodiment 3

[0047]1.0 g of 4,4'-diamino-4"-hydroxytriphenylmethane (DAHTM), 20.0 g of ECC202 epoxy resin, 20.0 g of 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl Ester epoxy resin, 15.0 g CE793 epoxy resin, and 45.0 g N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoro Put the propane epoxy resin into the reaction kettle, stir and mix at 100°C for 0.5 hours, then add 2.0 grams of BBMO-2 imide oligomer and continue to stir for 1 hour, then add 3.0 grams of 3-aminopropyltrimethoxy The silane was stirred and reacted for 5 minutes, cooled to room temperature, and then 20.0 grams of 1,8-diaza-bicyclo[5.4.0]undecene-7 and 30.0 grams of hexahydrophthalic anhydride were added, stirred and mixed uniformly to obtain 156.0 grams of DAHTM containing Silicon epoxy imide matrix resin, denoted as M-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com