Test device for simulating karst fissure-pipeline water and solute migration rule

A technology of solute migration and test equipment, applied in the field of test equipment, simulating karst fissure-pipeline water flow and solute migration rules, can solve problems such as single structure, difficult human life, weak operability, etc. The effect of controllable factors, reasonable space layout and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

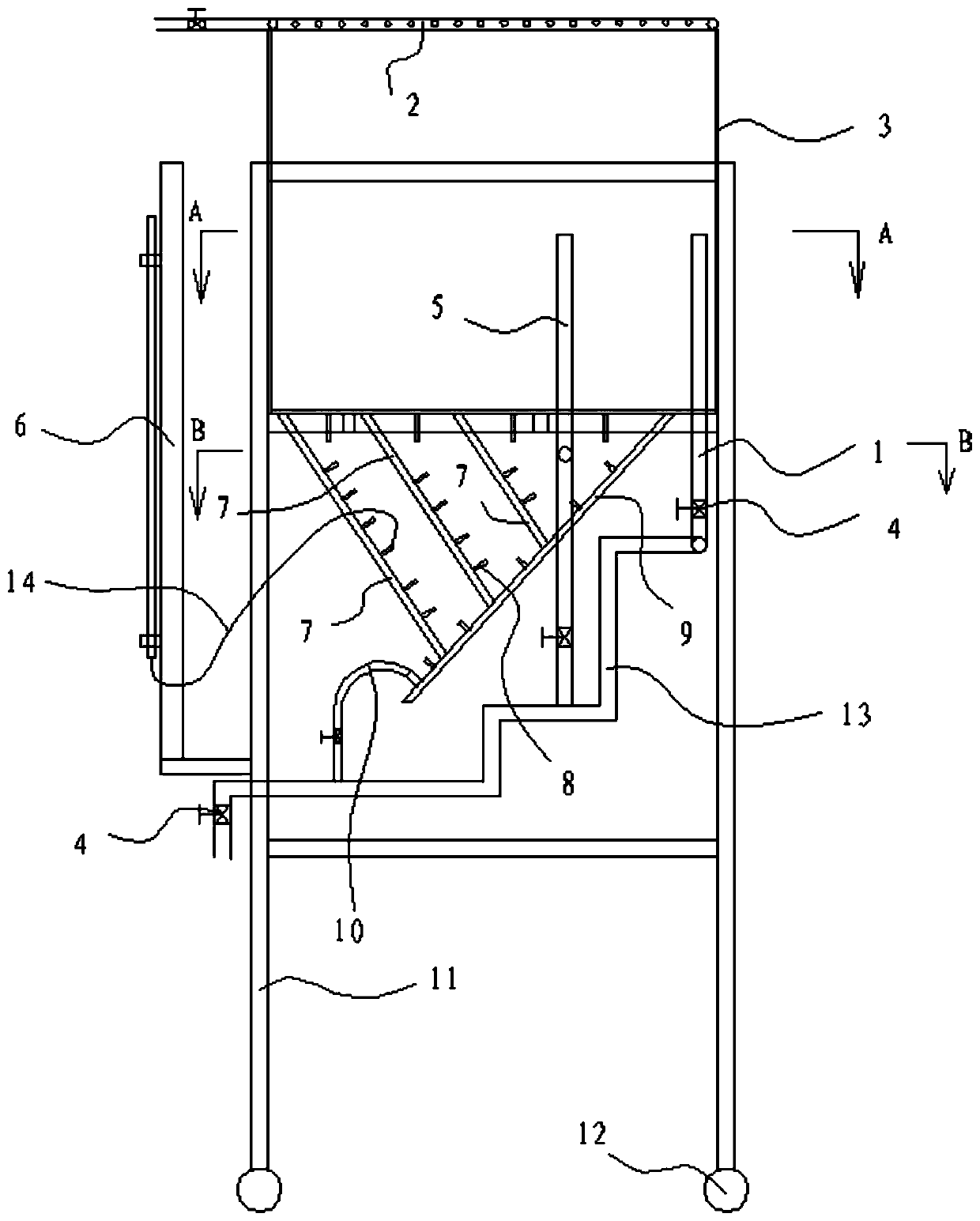

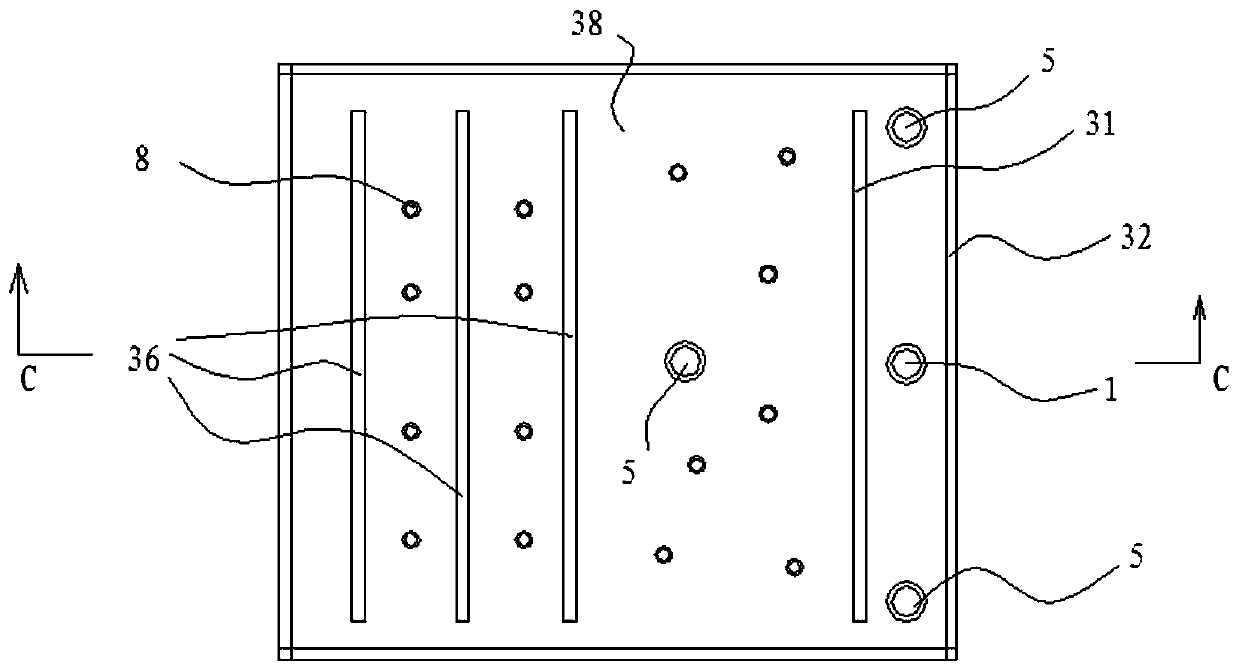

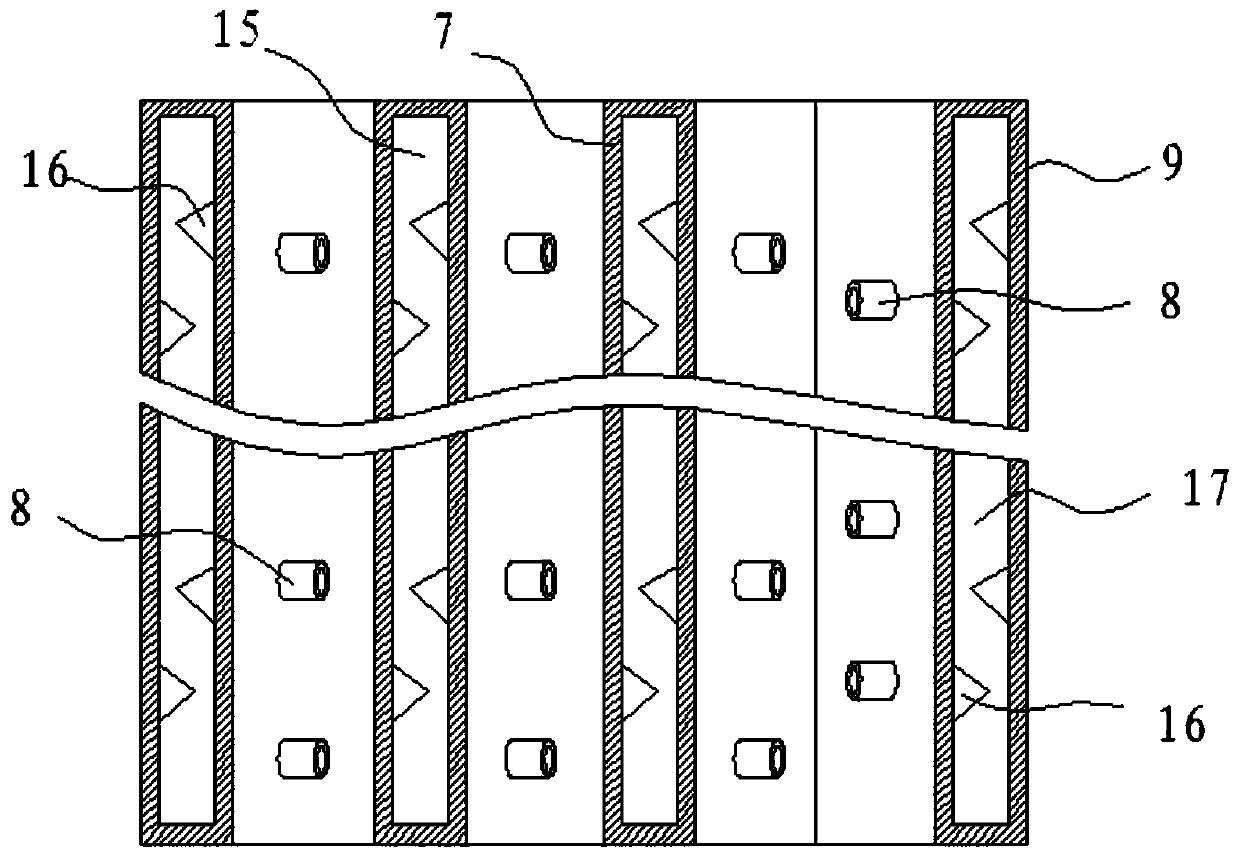

[0020] Embodiment 1: as attached Figure 1-7 As shown, a test device for simulating karst fissure-pipeline water flow and solute migration law, it includes a frame 11, the frame 11 is a fixedly connected square frame structure, and a surface karst zone is arranged on the top of the frame 11 The infiltration box 3 is provided with a pressure monitoring device 6 on the side of the frame 11. The surface karst zone infiltration box 3 is a square box structure, and the top of the surface karst zone infiltration box 3 is an open structure and placed The rainfall simulator 2 is connected with a large fissure plate 9 on one side of the bottom of the surface karst zone infiltration box 3, and three small fissure plates 7 are connected on the other side, and the bottom of the small fissure plate 7 is connected with the side of the large fissure plate 9 And it has a V-shaped structure. Large cracks 17 and small cracks 15 are respectively arranged inside the large crack plate 9 and the sm...

Embodiment 2

[0034] Embodiment 2: Karst fissure-pipeline spring flow decline process test procedure

[0035] Set up different water-containing channels, and after controlling the flow at the outlet to be stable, simulate their water-regression processes respectively. The test steps are as follows: ① Open the water valves on all channels to simulate the process of water retreat in the crack-pipeline. ② Turn on the water pump to supply water to the rainfall simulator. ③ Observe the state of the water flow at the outlet, and measure the flow value when the water flow obviously increases to remain basically unchanged. If the results of three consecutive monitorings are basically close, the next test can be carried out. ④ When the outlet flow is stable, turn off the water pump, stop the water supply, and start to simulate the water retreat process. ⑤ Monitor the change process of the flow at the outlet with time, and stop monitoring when the flow at the outlet decreases to basically unchanged...

Embodiment 3

[0036] Example 3: Solute transport test process in crack-pipe unsaturated flow: ① First, a submersible pump is installed in the water supply tank and connected to the water inlet of the rainfall simulator. ② After opening all the water migration channels in the crack-pipe, open the water valve at the water supply pipe of the rainfall simulator to supply water to the rainfall simulator. ③ Monitor the flow at the outlet, and when it reaches a stable level, the tracer can be prepared for the next test. ④ Draw out the pre-prepared carmine solution with a syringe with a volume of 20ml, inject it into the selected tracer injection point instantaneously, and press the timer at the same time to start timing. ⑤ Observe the migration of carmine in the cracks and pipelines. When the carmine is about to reach the exit, start sampling. During the period when the color is getting darker and darker, the sampling is intensive. The time interval is controlled within 3-5s, and the concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com