Deepwater semi-submerged drilling platform

A drilling platform and semi-submersible technology, applied in the direction of floating buildings, etc., can solve the problems of affecting the operation of the staff, reducing the service life, and high labor intensity, so as to achieve a reasonable layout of equipment space, improve the service life, and save the occupied area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

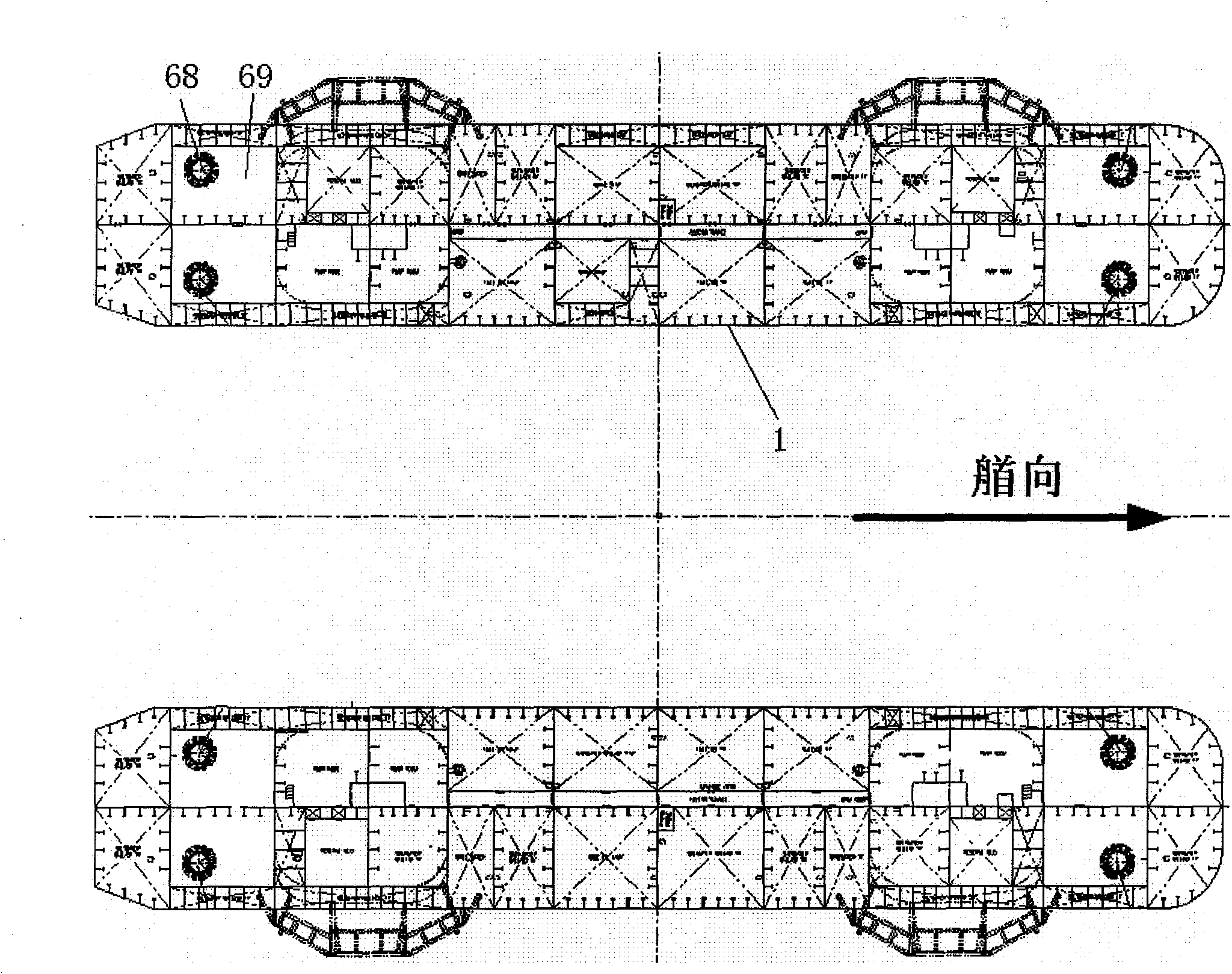

[0046] Such as Figure 1 ~ Figure 3 As shown, the present invention comprises two pontoon tanks 1, each pontoon tank 1 is 114.07m long, 20.12m wide, and 8.54m high, and the center distance between the two pontoon tanks 1 is 59.79m. Two columns 2 are connected to each buoyancy tank 1, and the columns 2 are 17.385m long, 15.860m wide and 21.46m high. The two columns 2 on each pontoon 1 are connected with the two columns 2 on the corresponding pontoon 1 through two sets of cross braces 3, and the top of the four columns 2 supports an upper hull 4, the upper hull 4 is 77.47m long and wide. 74.42m, the top of the upper hull 4 is the main deck 5 .

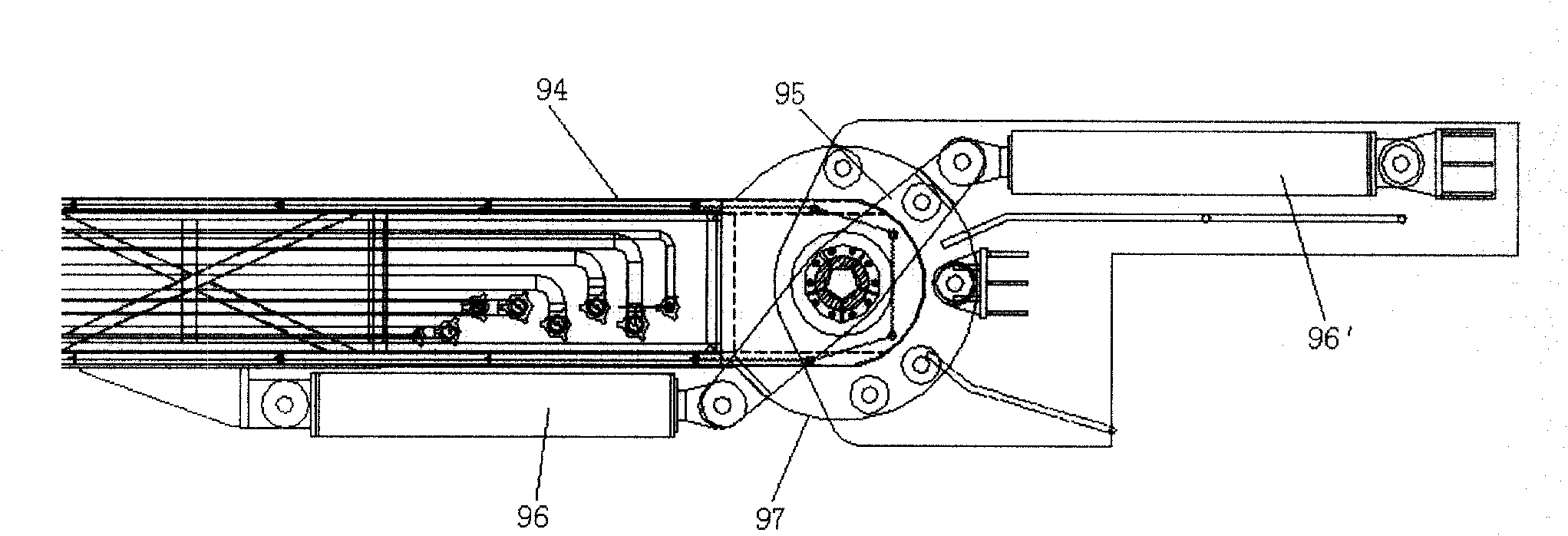

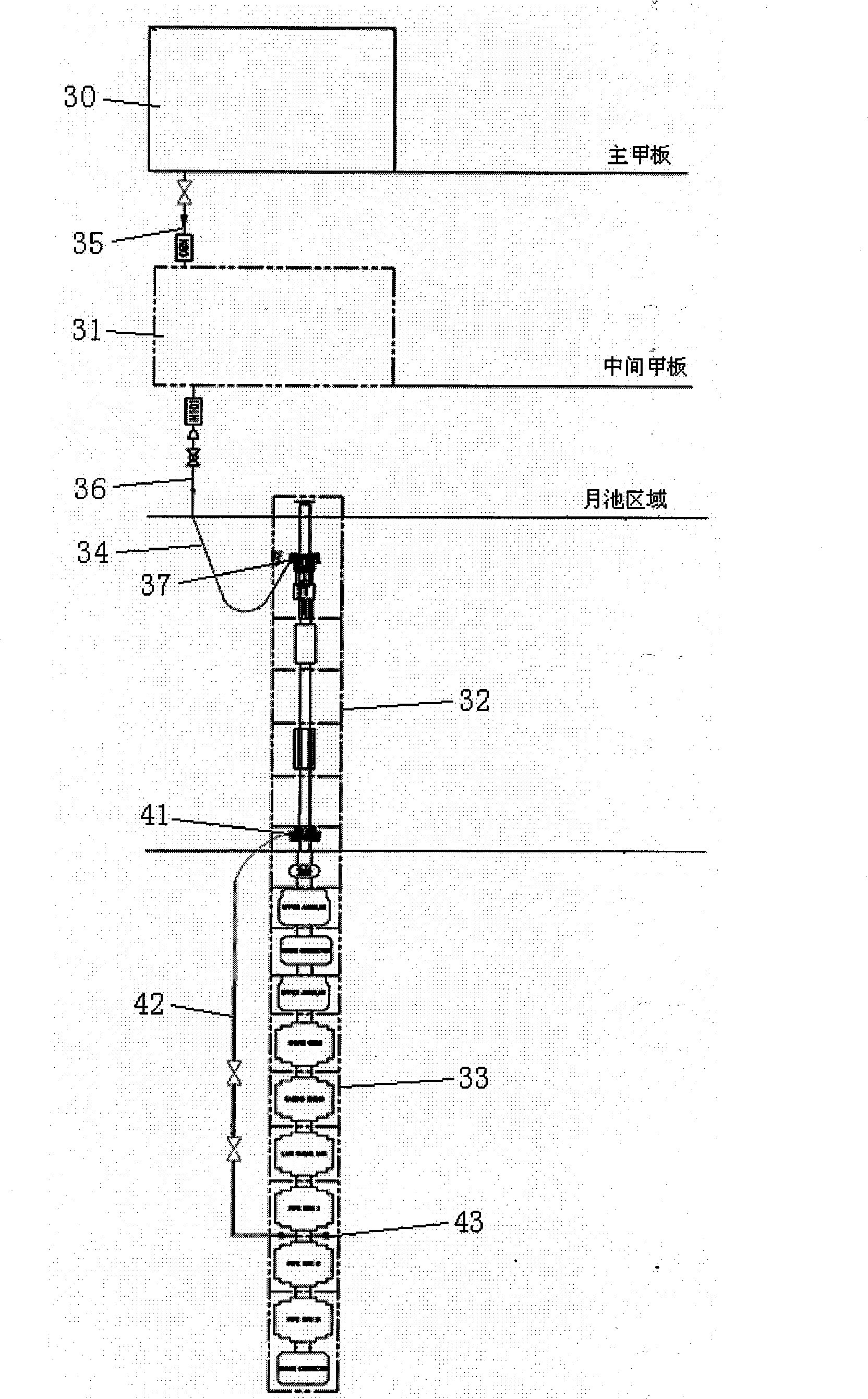

[0047] Such as Figure 1 ~ Figure 4 As shown, the present invention is provided with a drilling system above the moon pool 6 in the middle part of the main deck 5, and the drilling system includes a drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com