Woodworking straight line edge trimming machine

A trimming machine and straight line technology, which is applied in the direction of wood processing equipment, manufacturing tools, forming/shaping machines, etc., can solve the problems of high labor intensity for operators, high potential safety hazards, and low planing accuracy, so as to avoid operator injuries , work efficiency improvement, high processing precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

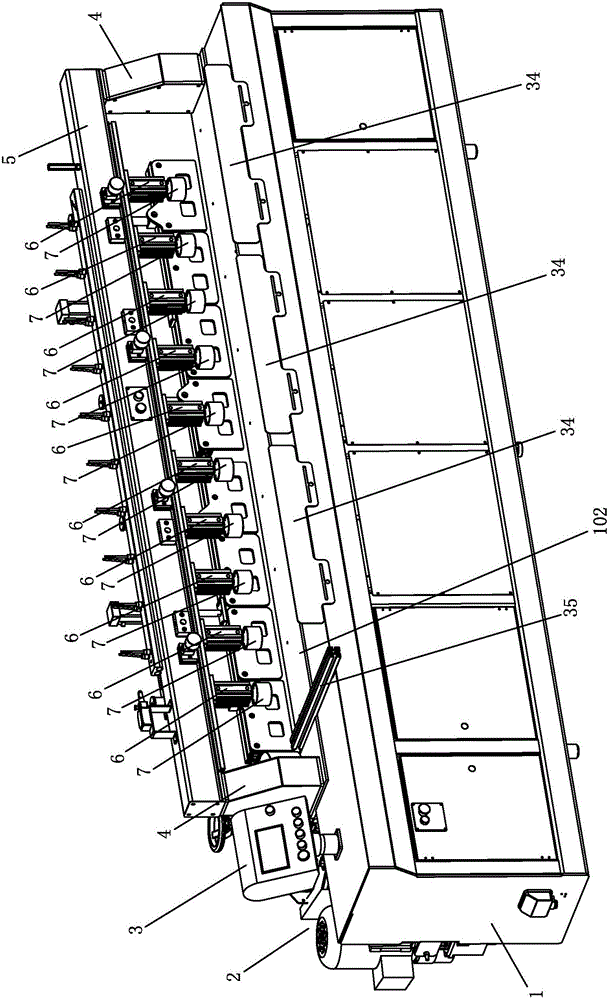

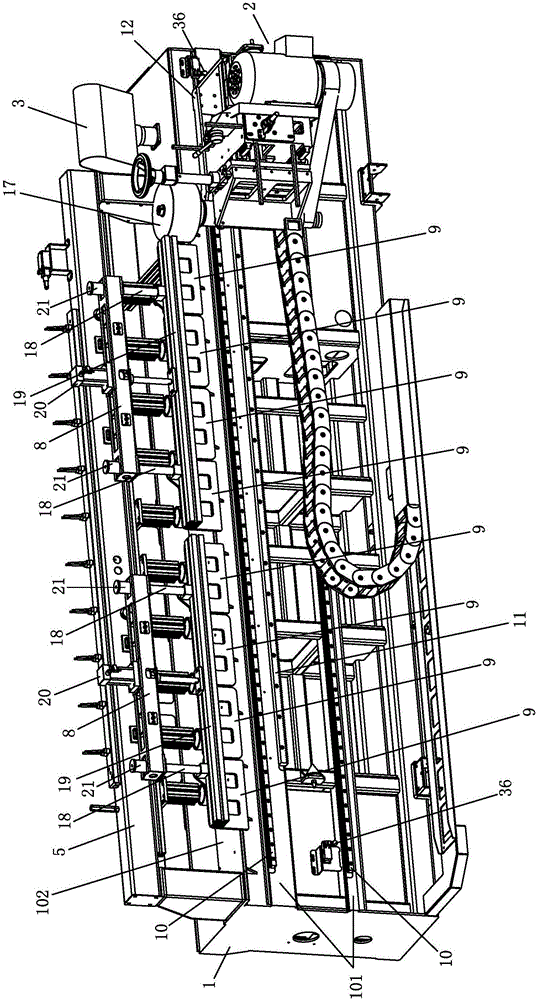

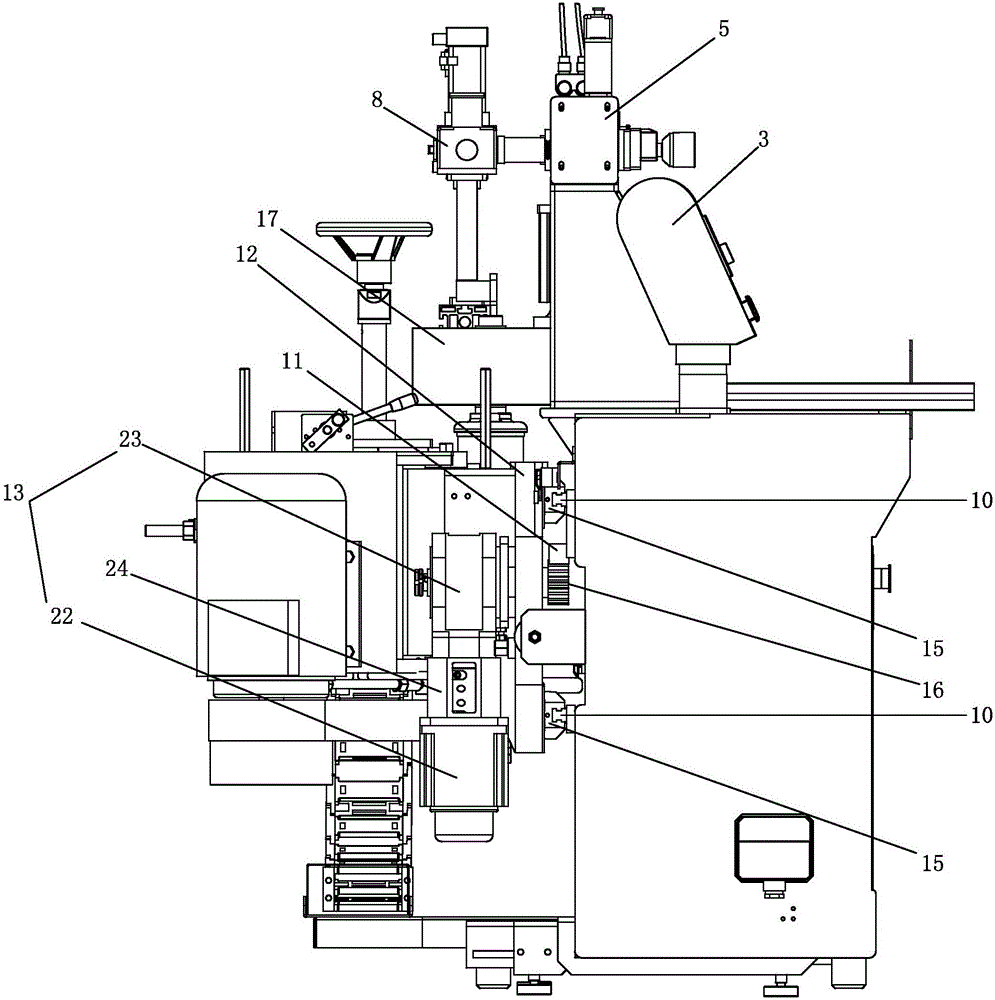

[0028] Such as Figure 1 to Figure 5 As shown, a woodworking linear trimming machine includes a machine base 1, a spindle device 2 installed on the rear end surface 101 of the machine base 1, and a control device 3. The machine base 1 is provided with a workbench 102 near the rear end surface 101 of the machine base 1. Two binder seats 4 are fixed on both sides of the workbench 102, and a binder beam 5 is connected between the two binder seats 4, which is characterized in that;

[0029] A plurality of binder cylinders 6 are vertically installed on the bottom surface of the binder beam 5, and the end of the telescopic rod of the binder cylinder 6 is connected with a binder head 7;

[0030] The rear end surface of the binder beam 5 is connected with at least one positioning seat 8, and the lower part of the positioning seat 8 is connected with an adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com