Recombination processing method for tobacco stem shreds

A processing method and technology for cut tobacco stems, applied in the field of cigarette processing and manufacturing, can solve the problems of low uniform absorption of feed liquid by cut stems, difficulty in feeding a large proportion of materials, loss of aroma components, etc., so as to enhance core competitiveness and improve usage. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

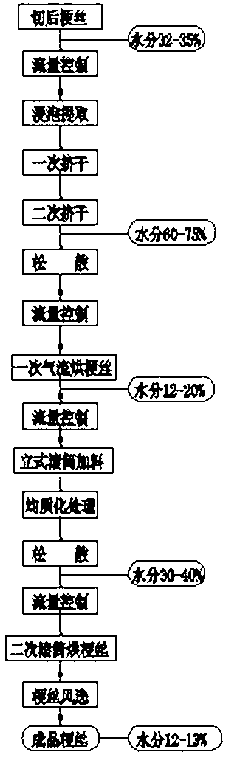

[0035] Such as figure 1 Shown, preferred technological process of the present invention is:

[0036] 1. Shredded stems: use the conventional shredded stems of the existing silk thread of the cigarette manufacturing enterprise, and the moisture content of the cut stems is about 32-35%;

[0037] 2. Primary flow control: after cutting, the cut stems are accurately determined by the first flow control unit to determine the amount of cut stems to be processed;

[0038] 3. Soaking and extraction: the cut stems enter the continuous soaking and extraction equipment through the flow control unit, and use normal temperature water as the extraction solvent. The ratio of water to cut stems is calculated as (5-8) per kilogram: 1, and the cut stems are soaked in water The time is 30-70 minutes;

[0039] 4. One-time squeezing and two-time squeezing: the extracted high-moisture shredded stems are pumped by the screw pump to the two-stage screw-type squeezer for two consecutive solid-liquid se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com