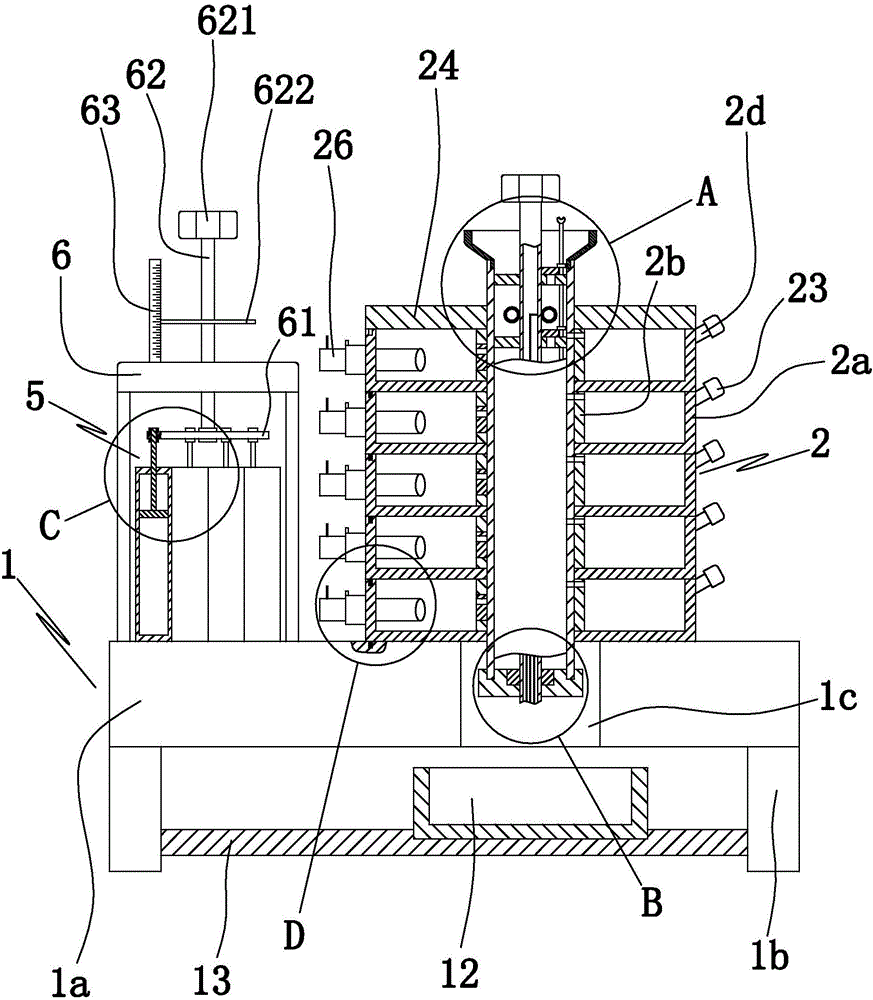

Culture carrier structure for test

A culture carrier and test technology, which is applied in tissue cell/virus culture devices, specific-purpose bioreactors/fermenters, biochemical instruments, etc., can solve problems such as deficiencies, achieve high accuracy, convenient operation process, good adjustment consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

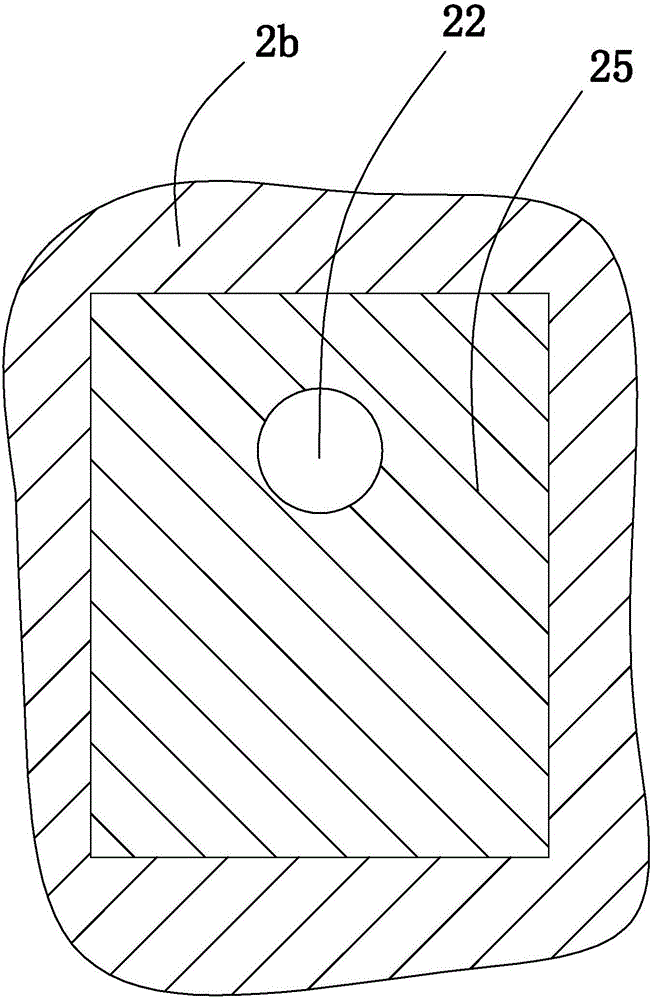

Method used

Image

Examples

example 1

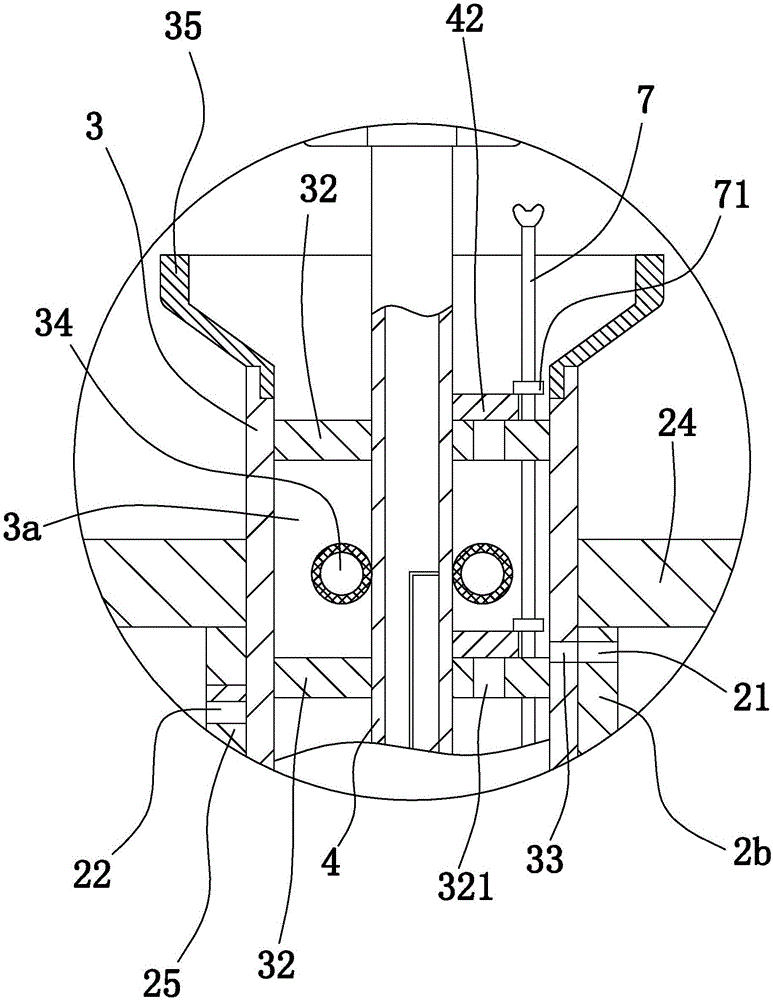

[0042] Example 1: In the circumferential direction of the rotating tube, the drain groove, the liquid equalizing hole, the tube liquid supply hole, and the cylinder liquid supply hole are sequentially arranged in a clockwise direction. During the operation of liquid equalization control (that is, the aforementioned process of draining liquid through the liquid equalization hole to make the liquid volume in each dish consistent), the liquid drainage tank rotates clockwise with the rotating tube to align with the liquid equalization hole (during this process, the tube feeds liquid hole is not connected to the liquid supply hole of the corresponding tube), after the liquid equalization control is completed, the liquid discharge tank continues to rotate clockwise and is staggered from the liquid equalization hole. At this time, the liquid supply hole of the tube and the liquid supply hole of the corresponding cylinder are still not connected. Then, if you continue to rotate the rot...

example 2

[0043] Example 2: In the circumferential direction of the rotating tube, the uniform liquid hole, the liquid drainage groove, the liquid supply hole of the tube, and the liquid supply hole of the cylinder are arranged in a clockwise direction, and the liquid is controlled (that is, the liquid is drained through the liquid uniform hole as described above) The process of making the liquid volume in each dish consistent) During operation, the liquid discharge tank rotates counterclockwise with the rotating tube to align with the liquid equalization hole (during this process, the liquid supply hole of the tube is not connected to the liquid supply hole of the corresponding cylinder), and the liquid control volume After the completion, the liquid discharge tank rotates clockwise and is staggered with the liquid equalizing hole. At this time, the liquid supply hole of the tube and the liquid supply hole of the corresponding cylinder are still not connected. Then, if you continue to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com