Motor brush rocker and carbon brush elastic force dynamic test device and test method

A dynamic test, motor brush technology, applied in the direction of measuring device, elasticity test, machine/structural component test, etc., can solve the problem of lack of dynamic test in elasticity test, achieve good application and promotion prospects, save time, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, dynamic test device and test method for carbon brush elastic force of motor brush holder

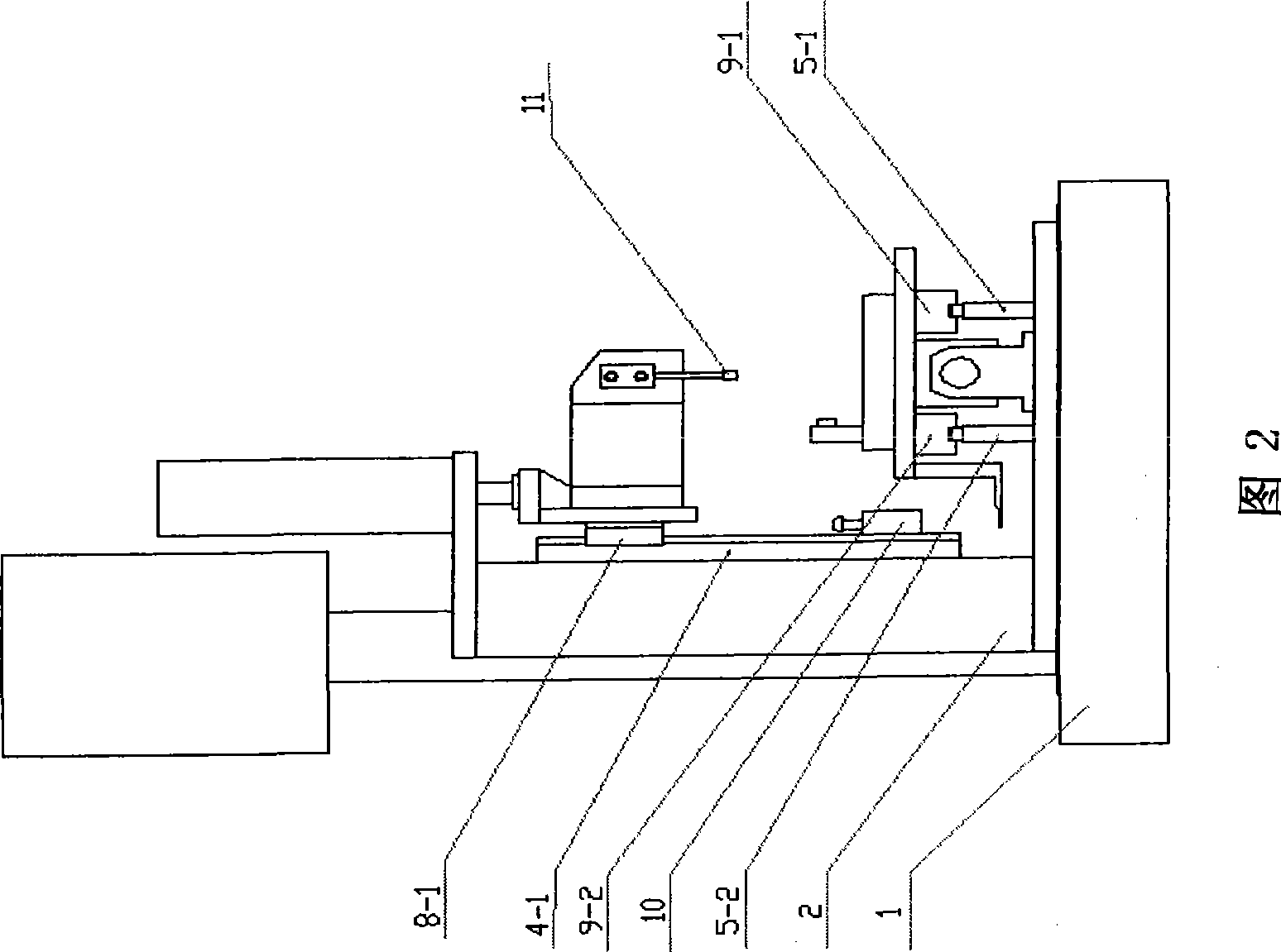

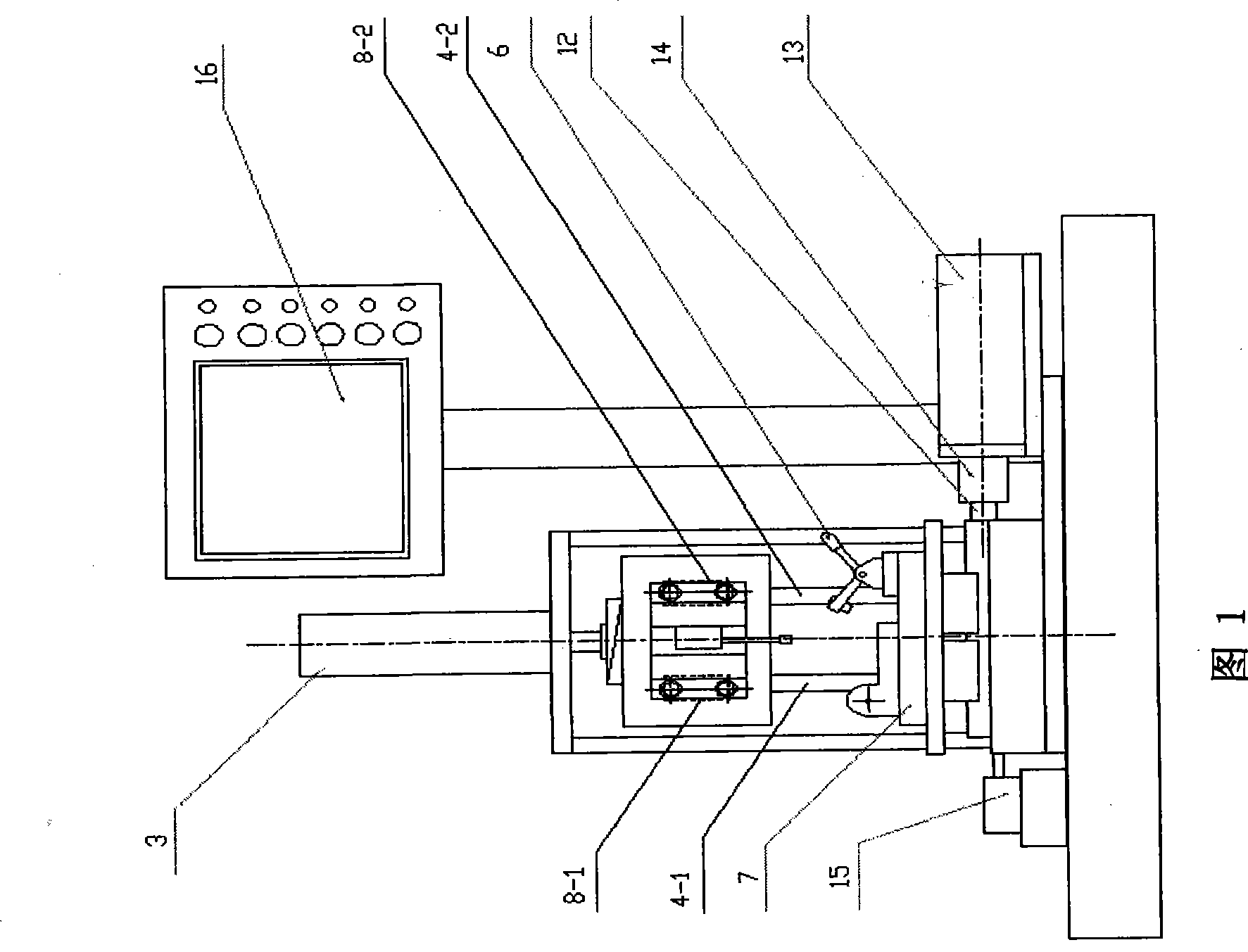

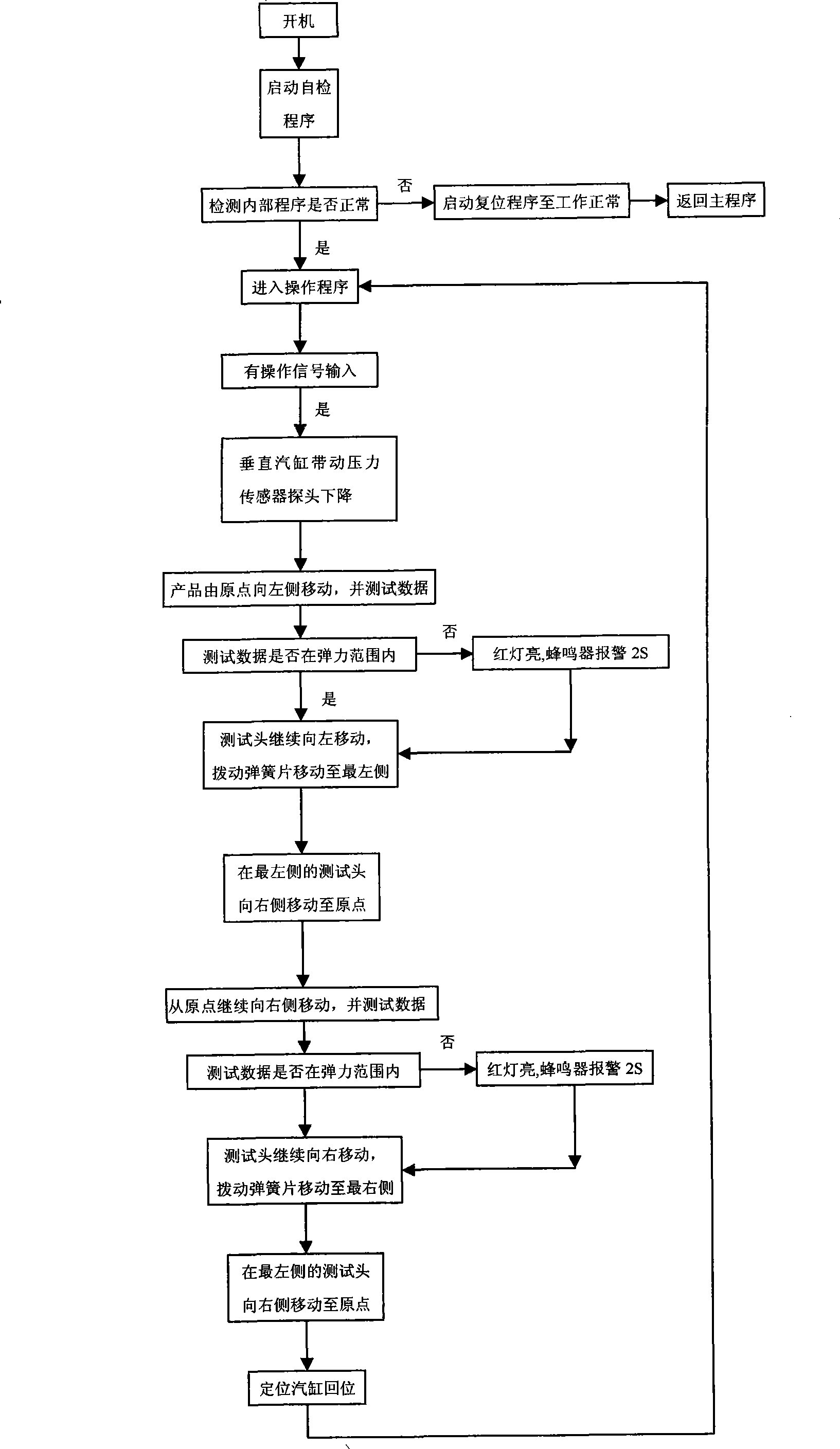

[0017]The dynamic elastic force test of the motor brush frame of the automobile ABS braking system is carried out by adopting the dynamic testing device and the testing method of the carbon brush elastic force of the motor brush frame of the present invention. The test device consists of a base plate 1, a frame 2, a vertical cylinder 3, left and right linear guide rails 4-1, 4-2, front and rear linear guide rails 5-1, 5-2, positioning and fixing claws 6, positioning tooling 7, and left and right linear bearings 8 -1, 8-2, front and rear linear bearings 9-1, 9-2, damping limit nail 10, pressure sensor 11, screw rod 12, servo motor 13, coupling 14, displacement sensor 15, programmable network digital monitoring Composed of COMO VIEW 16, the frame 2 is erected on the bottom plate 1, the vertical cylinder 3 is arranged on the upper end of the frame 2, and the pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com