Chemical gas exhaustion collection control detection system in the tank

A chemical gas, control and detection technology, applied in the direction of program control system, general control system, control/regulation system, etc., can solve the problems of gas exhaustion, waste, pollution, etc., achieve the effect of avoiding pollution and waste, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

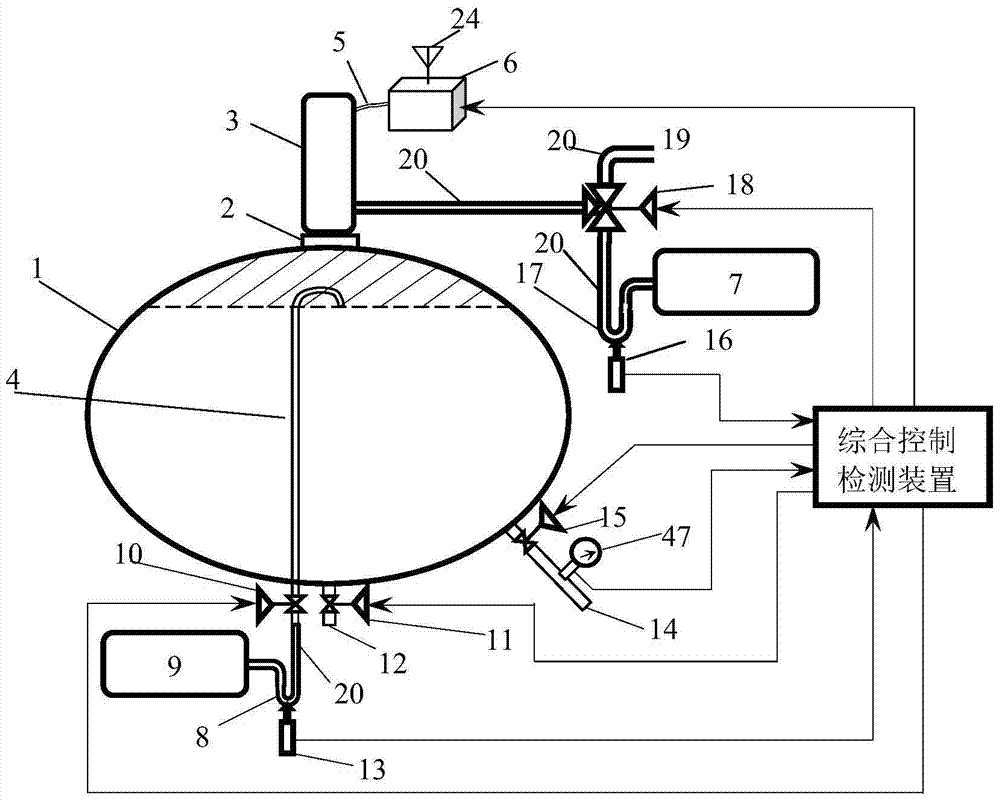

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

[0036] The integrated control detection device in the present invention can be selected to be placed in the management office or on-site according to different actual situations; the outside of the on-site safety valve opening and closing drive control device 6 is an instrument body with explosion-proof sealing and waterproof sealing, in order to reduce the external electromagnetic environment For the electromagnetic interference of drive control and tension signal transmission, the on-site safety valve opening and closing drive control device 6 must be at a position closer to the safety valve opening device 3 on site.

[0037] The system of the present invention automatically collects and exhausts all the chemical gases in the tank. The whole process can be divided into five stages. After the comprehensive control and detection device receives the input information from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com