Device for automatically installing snap spring

A technology of automatic installation and circlips, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of affecting the sealing of the assembly, high labor intensity, and low production efficiency, so as to improve product quality, reduce labor intensity, and improve operation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

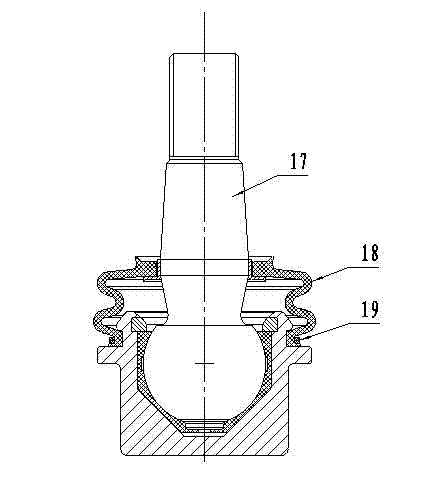

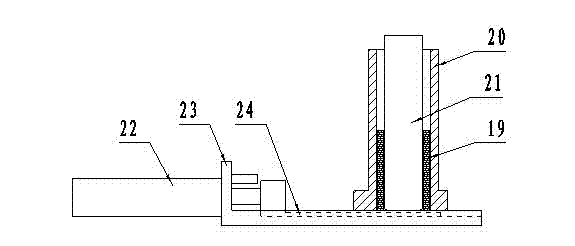

[0020] The present invention completes the structural principle of functional action as:

[0021] see Figure 1 to Figure 8 , the vertical cylinder 1 drives the pressure sleeve 3 and the follower rod 5 (the inner diameter of the pressure sleeve 3 is larger than the diameter of the middle part of the follower rod 5 but smaller than the diameter of the upper end, and the follower rod 5 and the cylinder rod are elastically connected) to move downward, pressing The lower end of the sleeve 3 is fixed with a plurality of snap spring push rods 4 with an elastic ring, and the snap spring push rods 4 can be spread out or gathered, and the follower rod 5 contacts the cone 8 and pushes it to move downward to disengage from the horizontal baffle plate 12. The spring ejector rod 4 moves along with it during this process. After the internal diaphragm 11 of the cone cylinder 8 contacts the workpiece 15, the follower rod 5 is forced to shrink, and the spring ejector rod 4 slides along the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com