Servo-hydraulic double-feeding mechanism for numerical control vertical cylinder sleeve honing machine

A numerically controlled vertical feed mechanism technology, applied in honing machine tools, grinding machine parts, grinding drive devices, etc., can solve the problem that the processing accuracy is difficult to meet, and the long stroke reversing time cannot guarantee the processing of high-quality platform textures. Honing, slow stroke speed and other problems, to achieve the effect of precise microscopic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

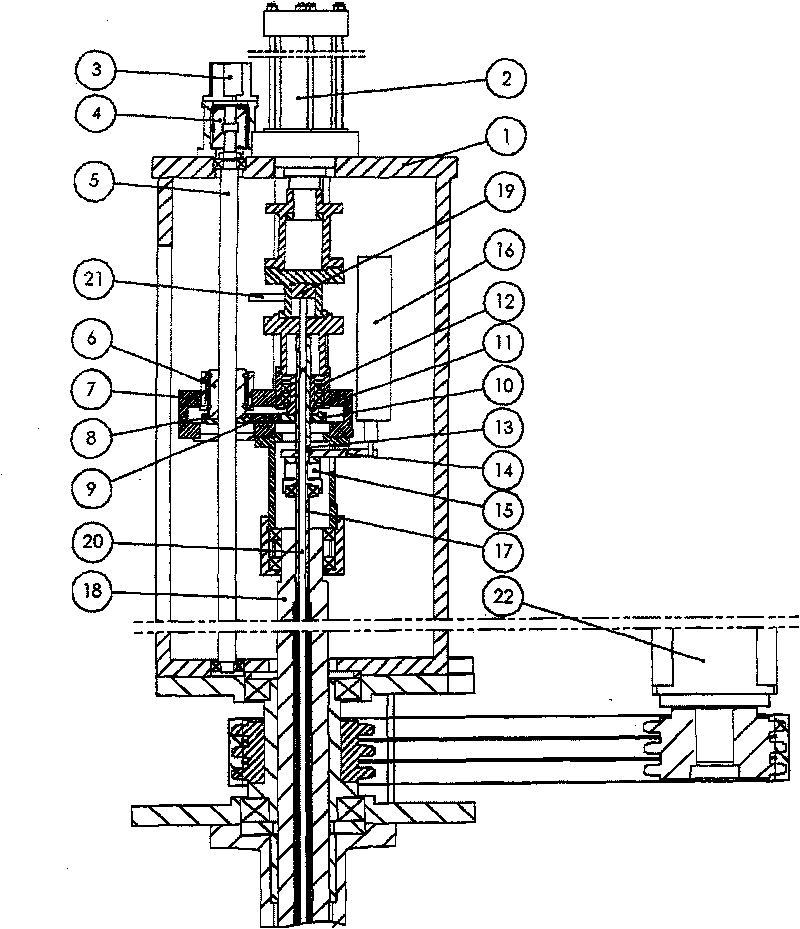

[0015] Such as figure 1 As shown in , a servo-hydraulic double-feed mechanism of a CNC vertical cylinder liner honing machine includes an inner push rod 20 and an outer push rod 17 located in the middle of a hollow stroke spindle 18, and the inner push rod 20 is located at the outer push rod 17 Inside; and the outer push rod 17 moves up and down under the drive of the servo feed closed-loop control mechanism, and the inner push rod 20 moves up and down under the drive of the hydraulic feed closed-loop control mechanism; the programmable digital control system and the servo feed closed-loop control mechanism and The sensors in the hydraulic feed closed-loop control mechanism are connected to realize the closed-loop feedback of the servo linear drive and the closed-loop feedback of the hydraulic drive; the digital control system is set outside the integral safety protection of the machine tool.

[0016] Both the inner and outer push rod feeding mechanisms of the honing head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com