Ice maker and refrigerator

A technology for ice machines and ice trays, which is applied in ice making, ice making, household refrigeration devices, etc. It can solve problems such as unsatisfactory use requirements, reduced utilization of cold air, and reduced air volume of ice trays, so as to improve ice production. Effect, efficiency improvement, effect of shortening ice making cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

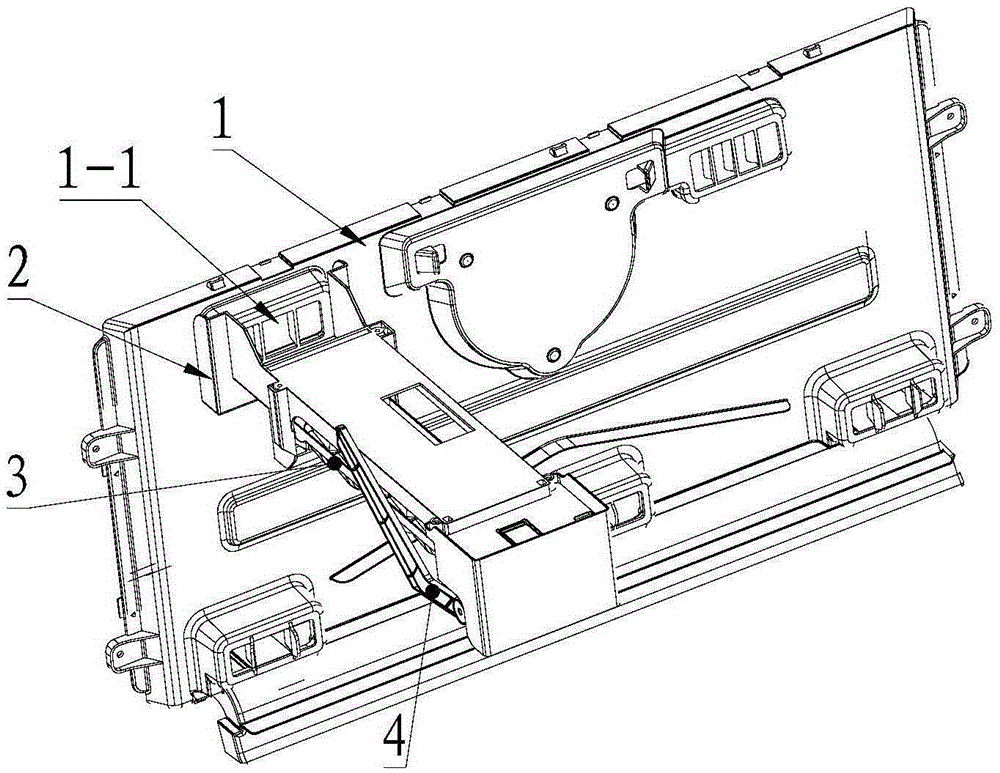

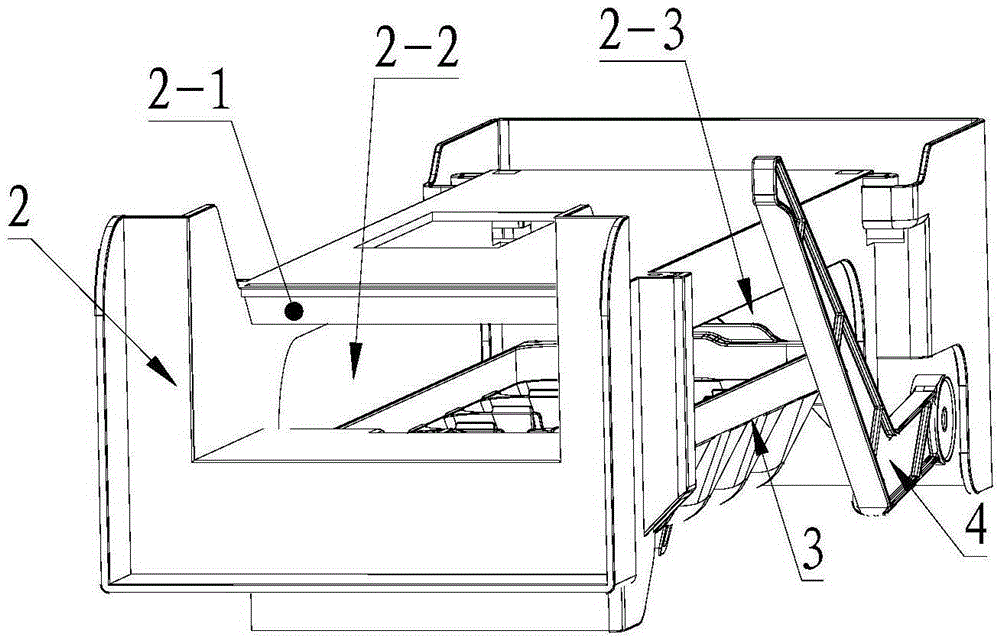

[0028] The bracket 2 is the installation and fixing base of the whole ice maker, and is mainly used for installing the ice-discharging motor 5, the ice-making tray 3 and forming a cavity, and the cavity is used for accommodating the ice-making tray 3 and for cooling air circulation. The lower edge of the air inlet is opposite to the upper surface of the ice-making tray 3. The cold air enters from the air inlet and passes through the upper surface of the ice-making tray 3. After completing the heat exchange, it is directly discharged from the air outlet. The air inlet and the ice-making tray 3, there is no obstacle between them, and there is no obstruction during the flow of cold air. From the entrance of the air inlet to the ice-making tray 3, the flow direction of the cold air in the horizontal direction remains unchanged. There is almost no loss of air volume; this structure can maximize the use of the air volume entering the air inlet, the amount of cold air passing through ...

Embodiment 2

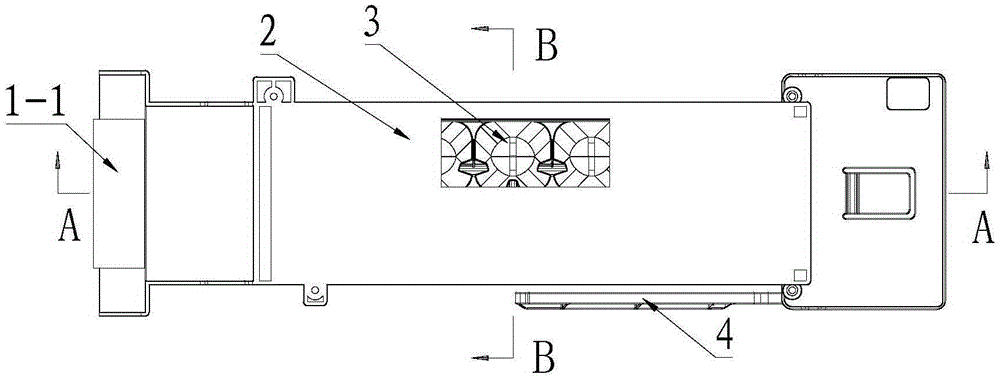

[0039] preferred, such as image 3 As shown, the ice machine can add water through the window opened on the top plate, and the water inlet pipe passes through the top of the storage room to add water to the ice-making tray 3 through the window. After the ice machine is installed, the window is blocked by the top of the storage room , forming a closed structure; only the end of the water inlet pipe protrudes, which will not affect the flow of cold air, and is conducive to the circulation of cold air.

[0040] Further, the storage room is a freezer room. The low-temperature environment of the freezer is conducive to further improving the ice-making efficiency.

[0041] The structure designed by the present invention can maximize the use of the air volume at the air outlet because there are no obstacles between the air outlet and the ice-making tray 3. At the same time, there are no obstacles on both sides of the ice-making tray 3, and the speed of the wind passing by It is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com