Method and device for preparing granular ice by freezing atomized water drops in cold carrying airflow

A technology of granular ice and refrigeration equipment, which is applied in ice making, ice making, lighting and heating equipment, etc. It can solve the problems that the thermal efficiency of ice making needs to be further improved, it is not suitable for large-scale ice making, and the ice making equipment is complicated. The effect of high ice efficiency, fast ice making speed and increased ice making energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

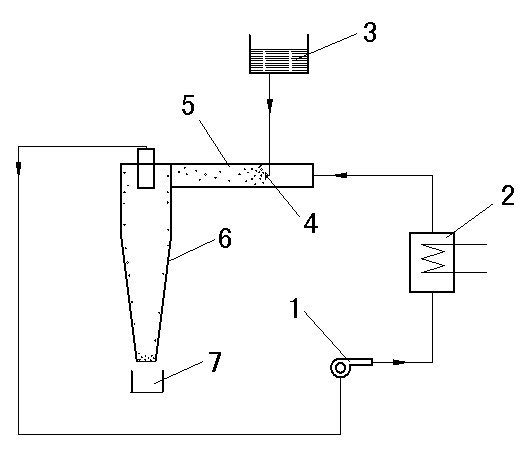

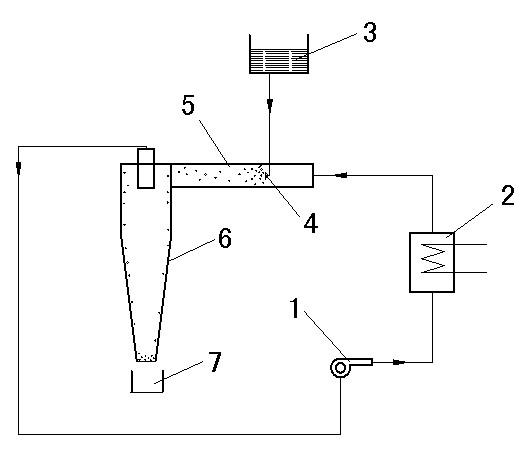

[0010] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] A method for producing granular ice by freezing atomized water droplets in a cold-carrying airflow of the present invention includes: firstly, through a circulating booster fan 1, transporting the cold-carrying airflow to a refrigeration device 2 for cooling to form a low-temperature airflow. The cold carrier gas stream can be air, carbon dioxide or nitrogen. Then, the low-temperature airflow is sent into the particle ice freezing channel 5 , and at the same time, the atomizing nozzle 4 sprays atomized water droplets into the particle ice freezing channel 5 . The atomized water droplets and the low-temperature air flow meet in the particle ice freezing channel 5 . The atomized water droplets are cooled by the low-temperature airflow and freeze into granular ice; during the freezing process, the atomized water droplets release heat to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com