Ice making system on refrigerator door

A refrigerator door and ice maker technology, applied in ice making, ice storage/distribution, household refrigeration equipment, etc., to achieve the effect of convenient manufacturing, high ice production efficiency, and not easy to freeze ice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

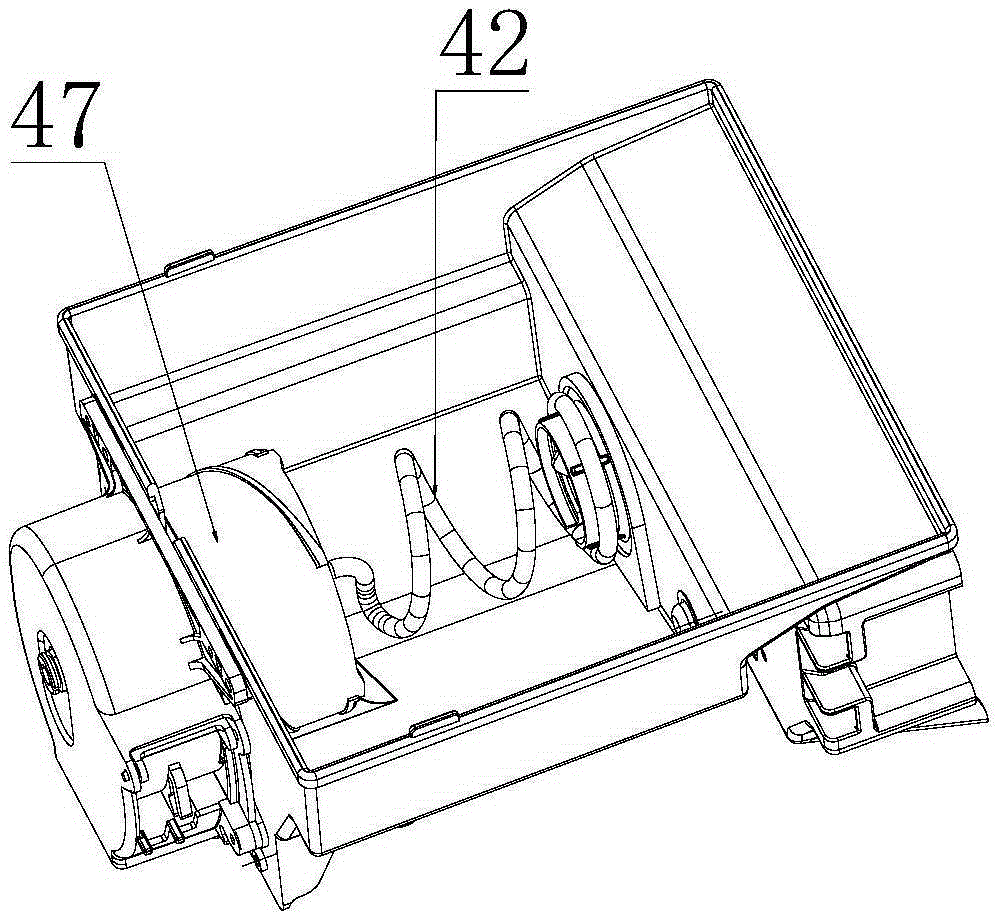

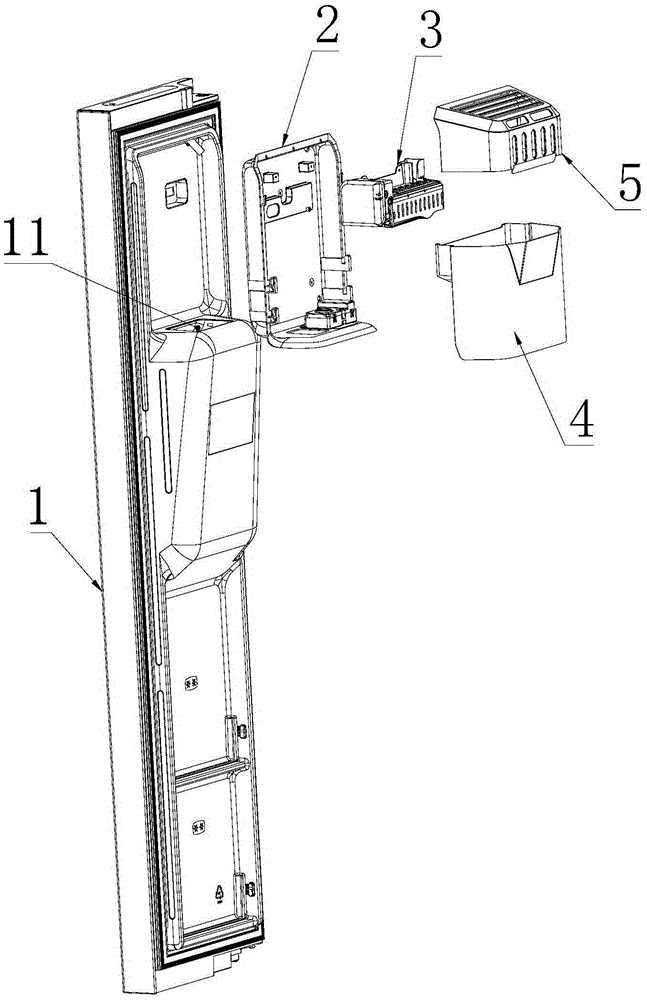

[0058] Such as image 3 , 6 , 7a, this embodiment discloses an ice-making system on the refrigerator door, including:

[0059] The ice maker 3 is installed on the inner side of the refrigerator compartment door 1;

[0060] The ice storage box 4 is installed inside the refrigerator door 1 and below the ice maker 3 for storing ice cubes made by the ice maker 3;

[0061] The distributor is arranged on the outside of the refrigerator door 1, and the distributor is connected with a distribution channel 11 extending to the bottom of the ice storage box 4;

[0062] The top of the ice storage box 4 is open, the ice storage box 4 is provided with a partition 46, and the ice cubes produced by the ice maker 3 are stored in the ice storage box 4 above the partition 46; The partition 46 is used as the bottom of the ice storage box 4, the top of the partition 46 stores ice, and the bottom of the partition 46 discharges ice.

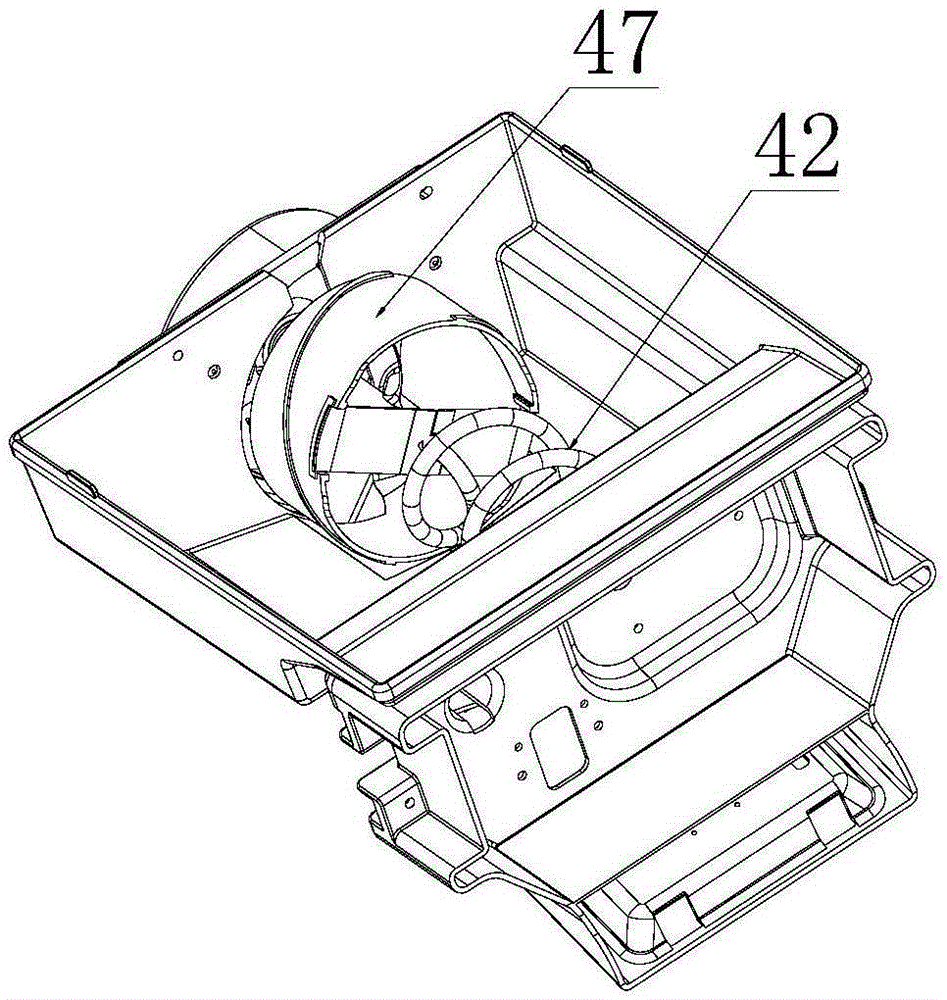

[0063] An ice outlet channel 41 and an ice drop channel 44 ar...

Embodiment 2

[0081] This embodiment is basically the same as the embodiment, the only difference is: Figure 7a As shown, the ice outlet channel 41 communicates with the ice drop channel 44 at the junction of the side wall and the bottom wall 411, and there is a gap between the side wall of the ice outlet channel and the ice selection cylinder 47 for ice cubes to pass through. The gap is located directly above the ice drop channel 44; the ice selection cylinder 47 is used to pass the ice cubes dropped from the ice inlet 45 through the side wall and bottom wall 411 of the ice outlet channel 41 Push the joint of the ice drop channel 44 into it.

[0082] That is to say, the ice cubes can fall into the ice-falling channel 44 from the bottom surface of the side of the ice-selecting cylinder 47 at the same time. There is a gap in the ice-discharging channel 41, and the gap is located directly above the ice-falling channel 44. The ice cubes in the ice-selecting tube 47 After entering the gap fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com