Novel method and device for producing ice

A new type of ice crystal technology, used in ice making, ice making, deicing, etc., can solve the problems of hard ice, low ice making efficiency, and high energy consumption, and achieve low fresh-keeping temperature, small ice particles, and large contact surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

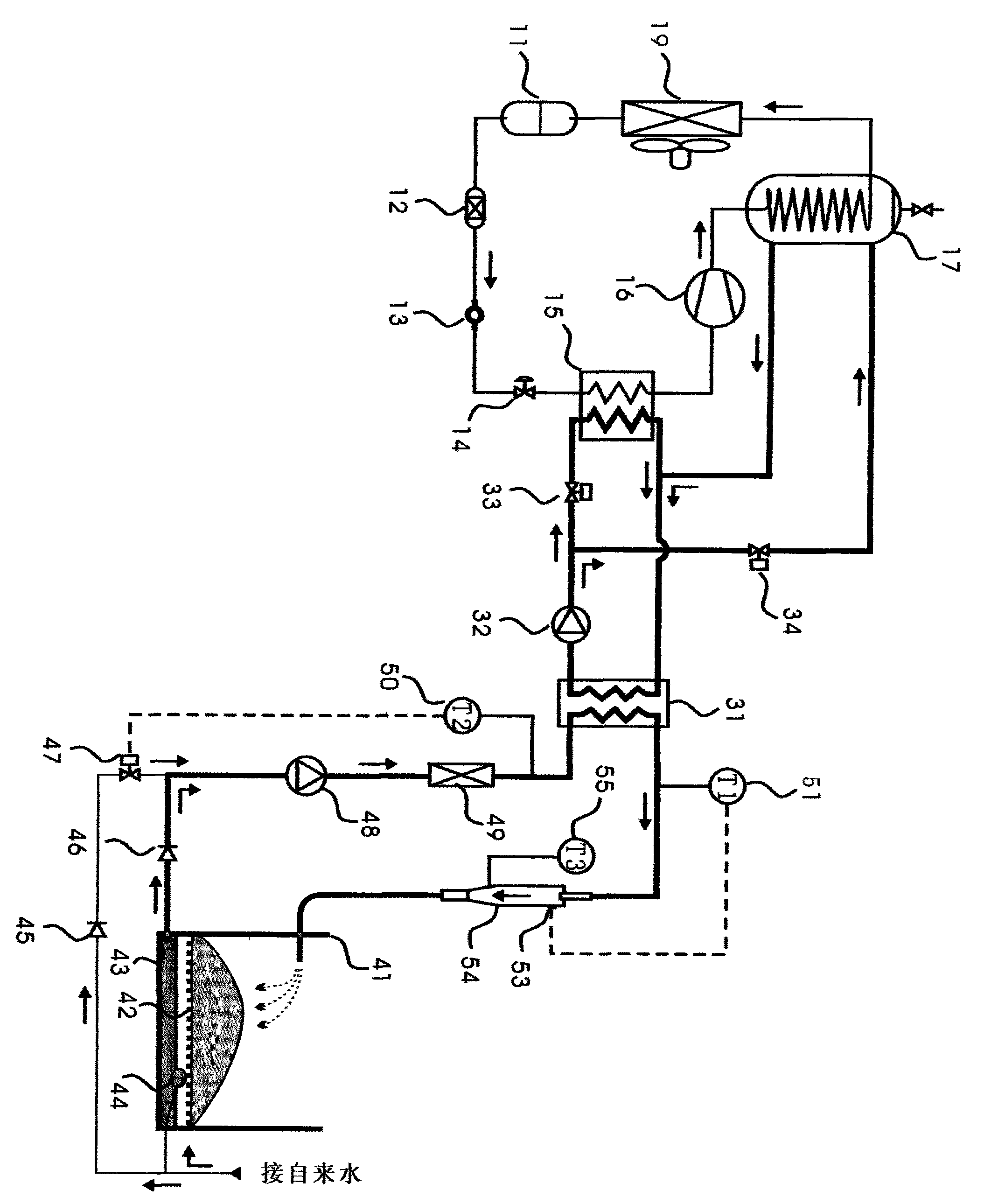

[0023] Such as figure 1 As shown, this embodiment is a case of a new type of ice-making device for the condensing thermal deicing scheme. A new type of ice-making method and device is divided into three major systems according to pipelines: a water system, a cooling system, and a refrigeration system. Each system is described in detail below.

[0024] The waterway system is mainly composed of ice storage tank 41, water pump 48, ice-water separator 49, plate heat exchanger 31, and ice crystal generator 54, which are connected in series from end to end to form a water circulation system. The ice storage tank 41 is provided with a primary filter 42, which is mainly used to filter out water contained in the ice crystals. The bottom of the ice storage tank 41 is also provided with a water outlet, and the front end of the water outlet is connected to the secondary filter 43 to prevent ice crystals from being sucked out by the water flow. The ice storage tank 41 is also provided wi...

Embodiment 2

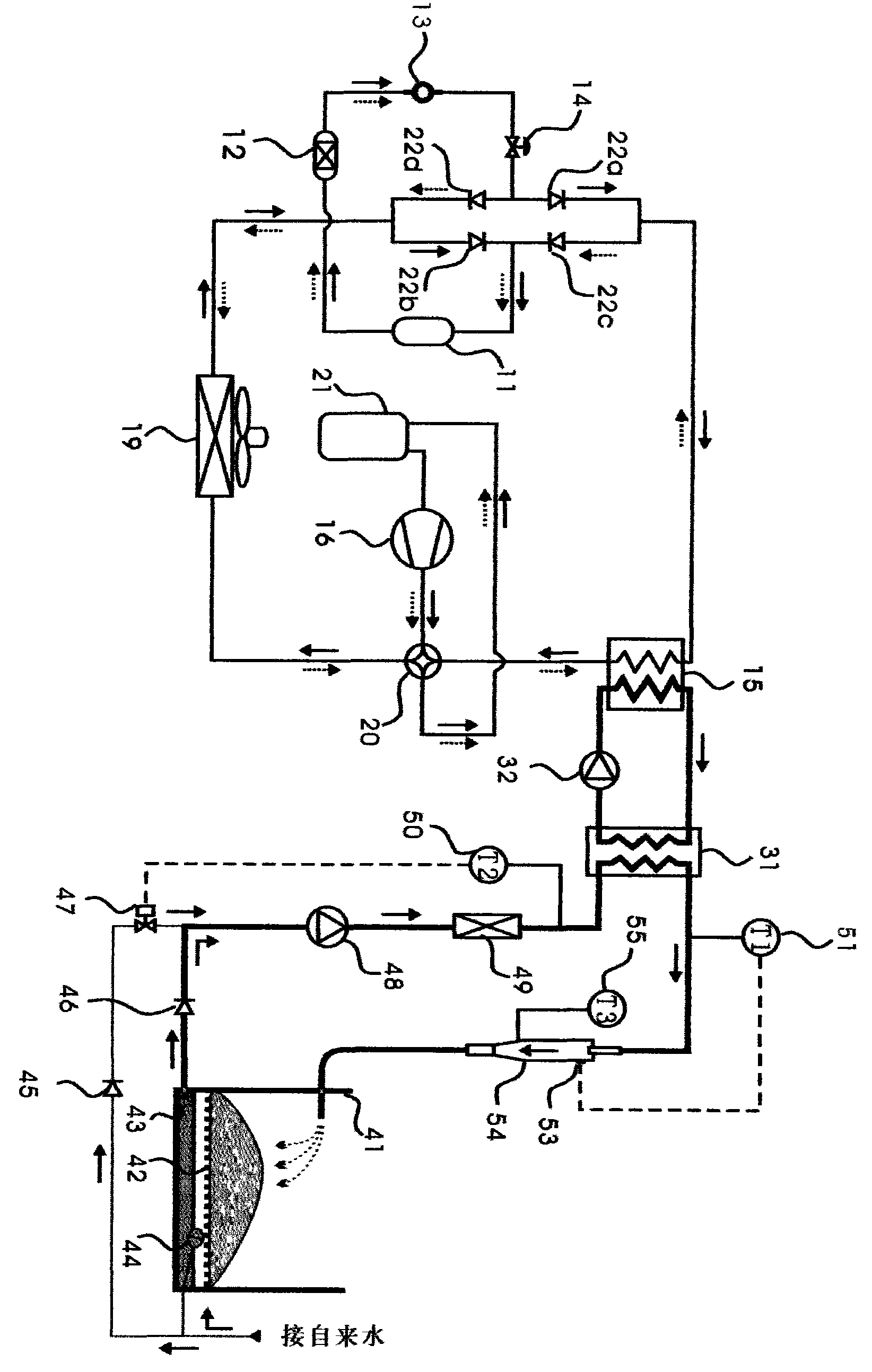

[0028] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 lies in the cooling system and the refrigeration system, and will be described in detail according to three major systems: the water system, the cooling system, and the refrigeration system.

[0029]The waterway system is mainly composed of ice storage tank 41, water pump 48, ice-water separator 49, plate heat exchanger 31, and ice crystal generator 54, which are connected in series from end to end to form a water circulation system. The ice storage tank 41 is provided with a primary filter 42, which is mainly used to filter out water contained in the ice crystals. The bottom of the ice storage tank 41 is also provided with a water outlet, and the front end of the water outlet is connected to the secondary filter 43 to prevent ice crystals from being sucked out by the water flow. The ice storage tank 41 is also provided with a water replenishment port, and the two ends of the water repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com