Ice making mold and ice making method thereof

A technology of ice-making molds and ice molds, which is applied in ice-making, ice-making, household appliances, etc. It can solve the problems of insufficient crystallinity, weak beverage taste, slow speed, etc., and achieve the effect of speeding up the ice-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

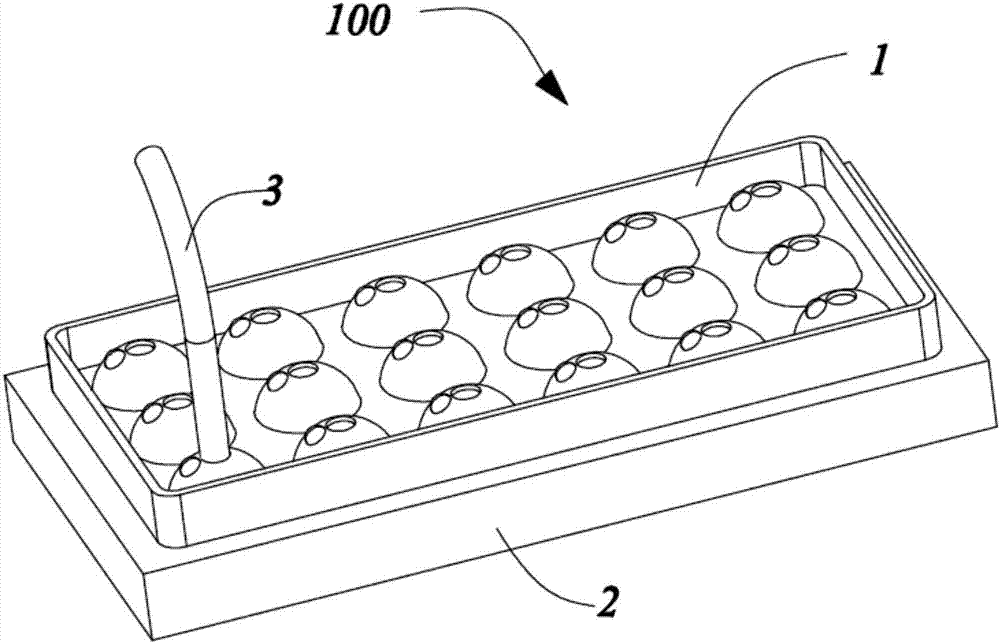

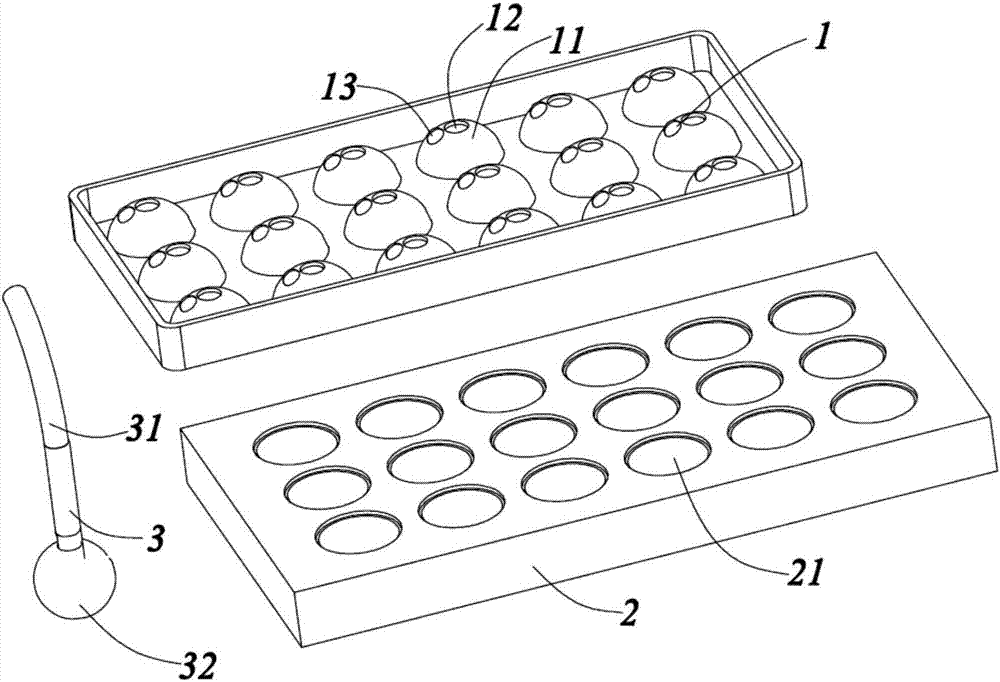

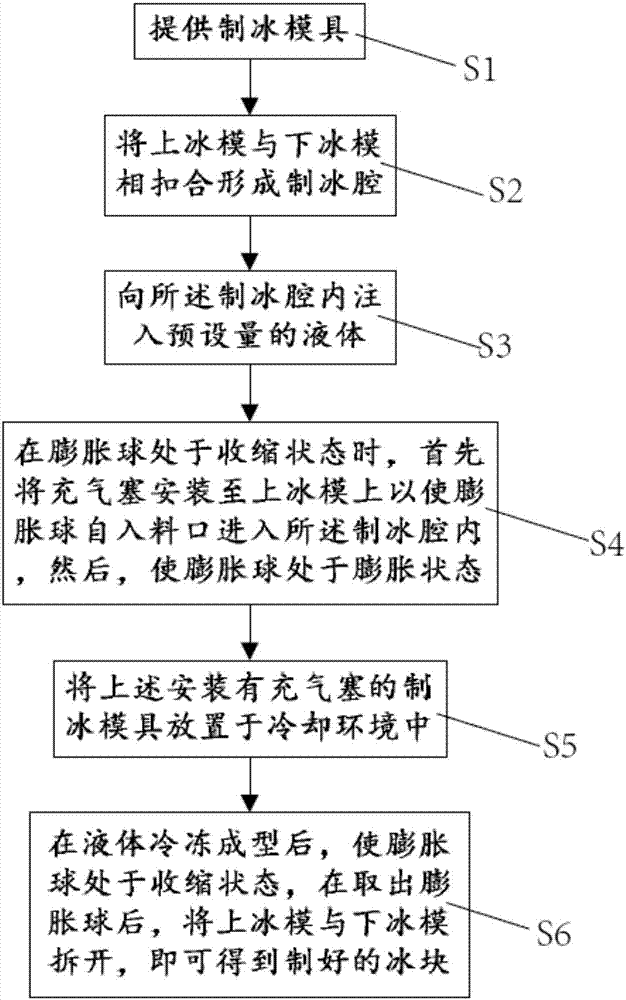

[0025] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings, please refer to Figure 1 to Figure 3 Shown is a preferred embodiment of the present invention.

[0026] Please refer to Figure 1 to Figure 3 Shown is an ice-making mold 100 for preparing hollow ice cubes provided by the present invention. The ice-making mold 100 includes an upper ice mold 1, a lower ice mold 2 matched with the upper ice mold 1, and an inflation plug 3 .

[0027] The upper ice mold 1 is provided with at least one first ice-making tray 11, and the lower ice mold 2 is provided with a second ice-making tray 21 corresponding to the first ice-making tray 11 one-to-one. After the upper ice mold 1 is fastened with the lower ice mold 2, the first ice-making tray 11 and the second ice-making tray 21 corresponding to the first ice-making tray 11 are surrounded to form an ice-making tray for making ice. The ice-making cavity, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com