Door ice making system for making transparent ice and refrigerator

A transparent, ice cavity technology, applied in the direction of ice making, ice making, ice storage/distribution, etc., to achieve the effect of increased ice production, good cooling effect and fast shedding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

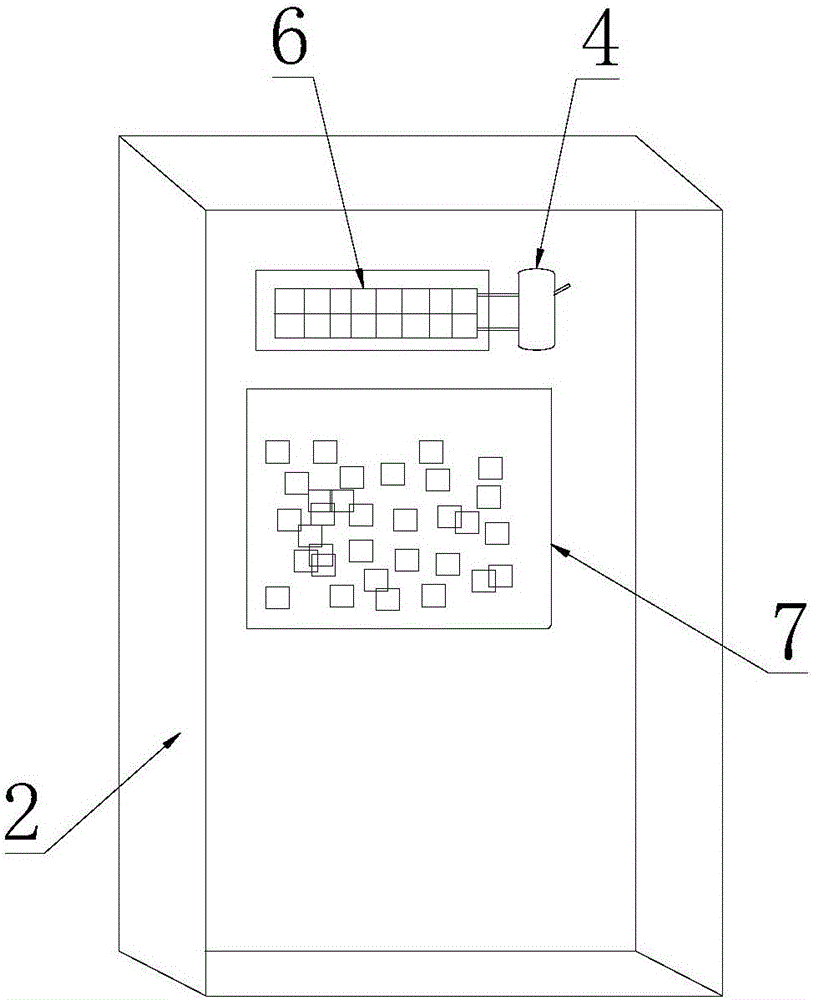

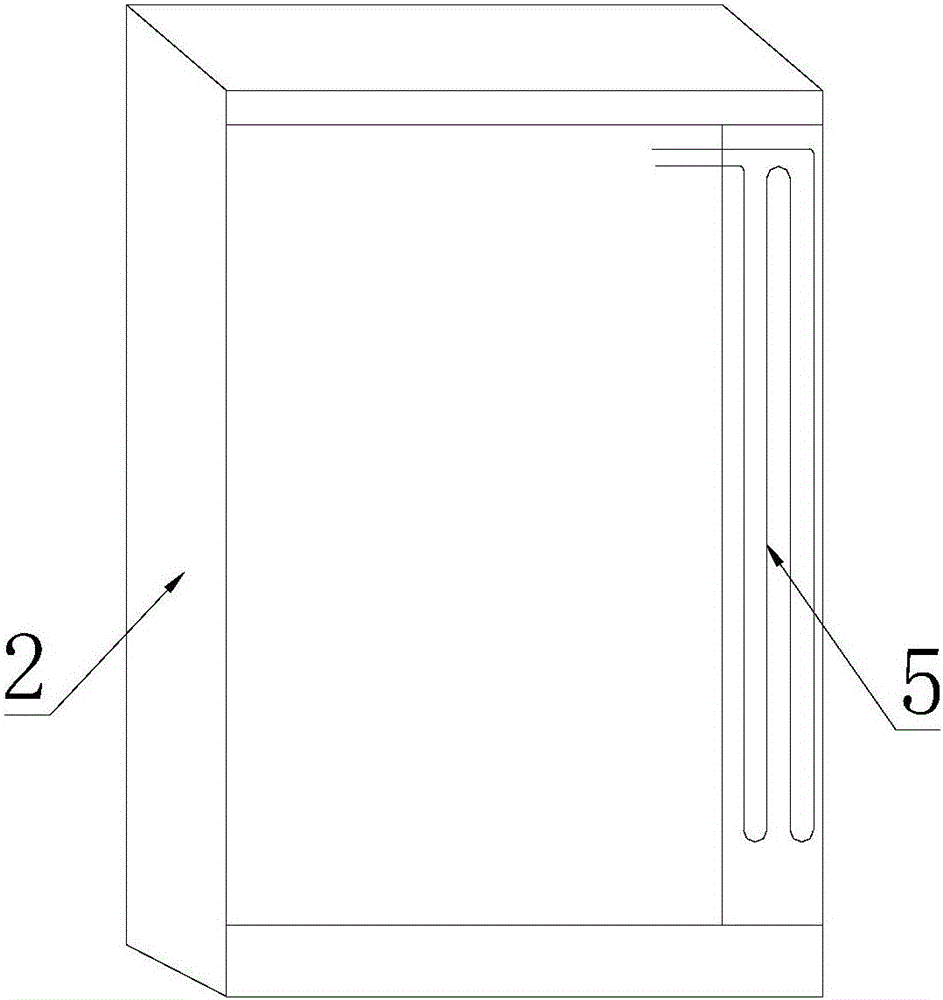

[0028] Such as Figures 2 to 4 As shown, the present invention discloses an ice-making system on the door for making transparent ice, which includes a refrigeration unit, an ice-making cavity and a water injection port arranged on the door body 2, and the refrigeration unit is composed of: a compressor 4, an evaporator 6. It is formed by closed-loop connection with the condenser 5, and the evaporator 6 penetrates into the ice-making chamber; the water injection port is connected with the ice-making chamber, and the water injection port is used to make the injected water The surface of the evaporator 6 flows to condense transparent ice on the surface of the evaporator 6 . All components of the refrigeration unit are arranged in the door body 2, and the cooling capacity is directly transferred from the surface of the evaporator 6 to the water, without the need to set up a cold air delivery channel, the loss of cooling capacity during the ice-making process is greatly reduced, an...

Embodiment 2

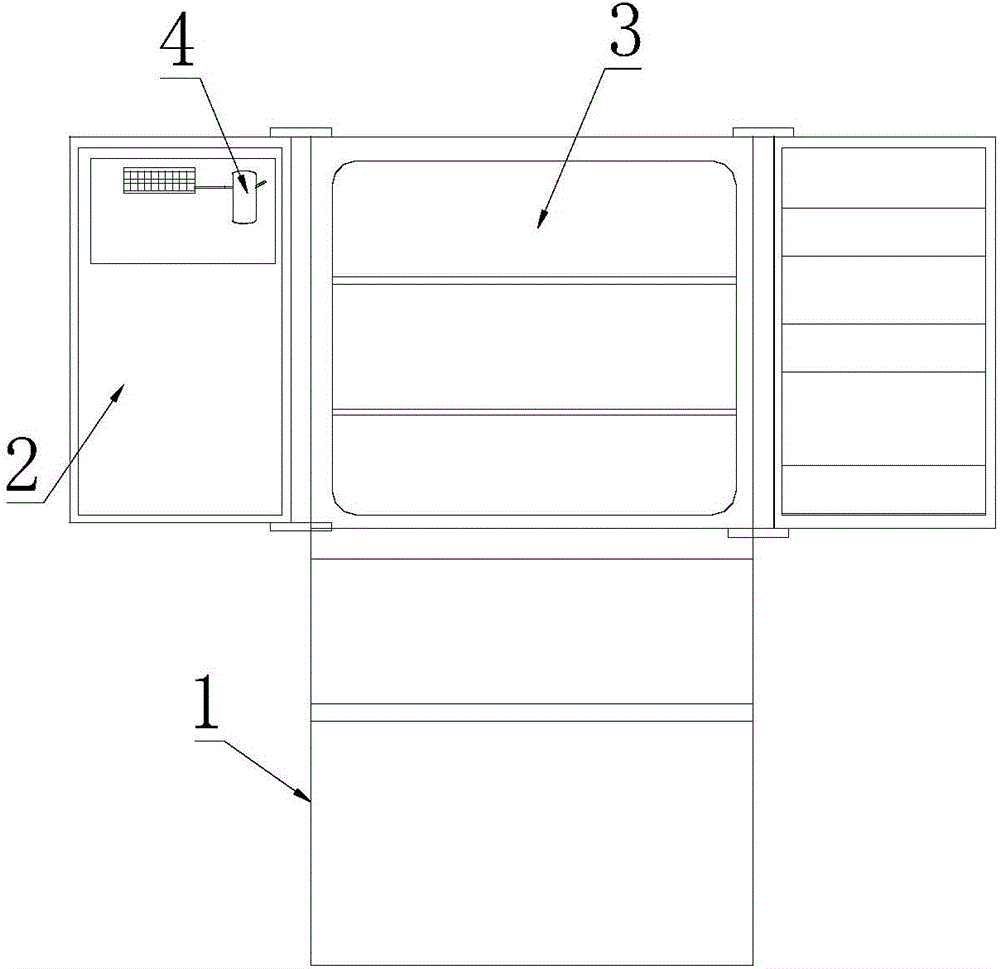

[0039] Such as figure 1 As shown, the present embodiment provides a refrigerator, the storage room 3 of the refrigerator is pivotally connected with a door body 2 for opening or closing the storage room 3, and the door body 2 has a transparent ice making function as described in the first embodiment. On-door ice-making system. For example, the on-door ice-making system for making transparent ice is set in the door body 2 of the refrigerator, and the on-door ice-making system for making transparent ice only needs to be connected to the power supply and controller of the refrigerator 1 through power lines and signal lines , can realize the operation of making ice independently in the door body 2, without drawing cold air from the cooling air duct of the refrigerator 1 to provide cooling capacity for ice making; this will not only reduce the loss of cooling capacity, but will not occupy the storage space of the storage room 3 of the refrigerator 1 space, increasing the storage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com