Ice maker

An ice maker and refrigerant technology, which is applied in the directions of ice making, ice making, refrigerators, etc., can solve the problems of long ice harvesting time by hot gas bypass, affecting ice production and system efficiency, and low system efficiency, so as to shorten the time. The effect of harvesting time, shortening harvesting time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

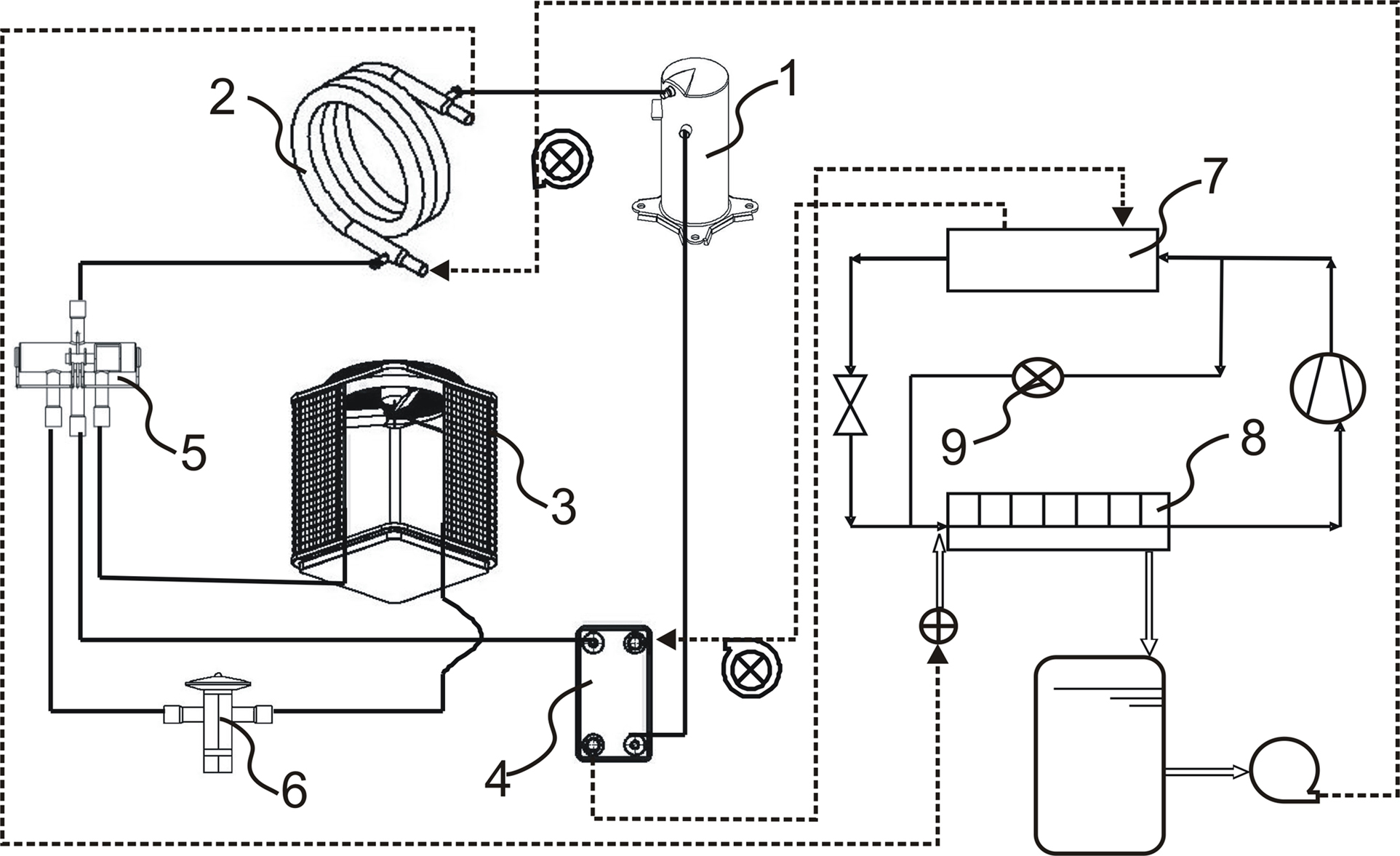

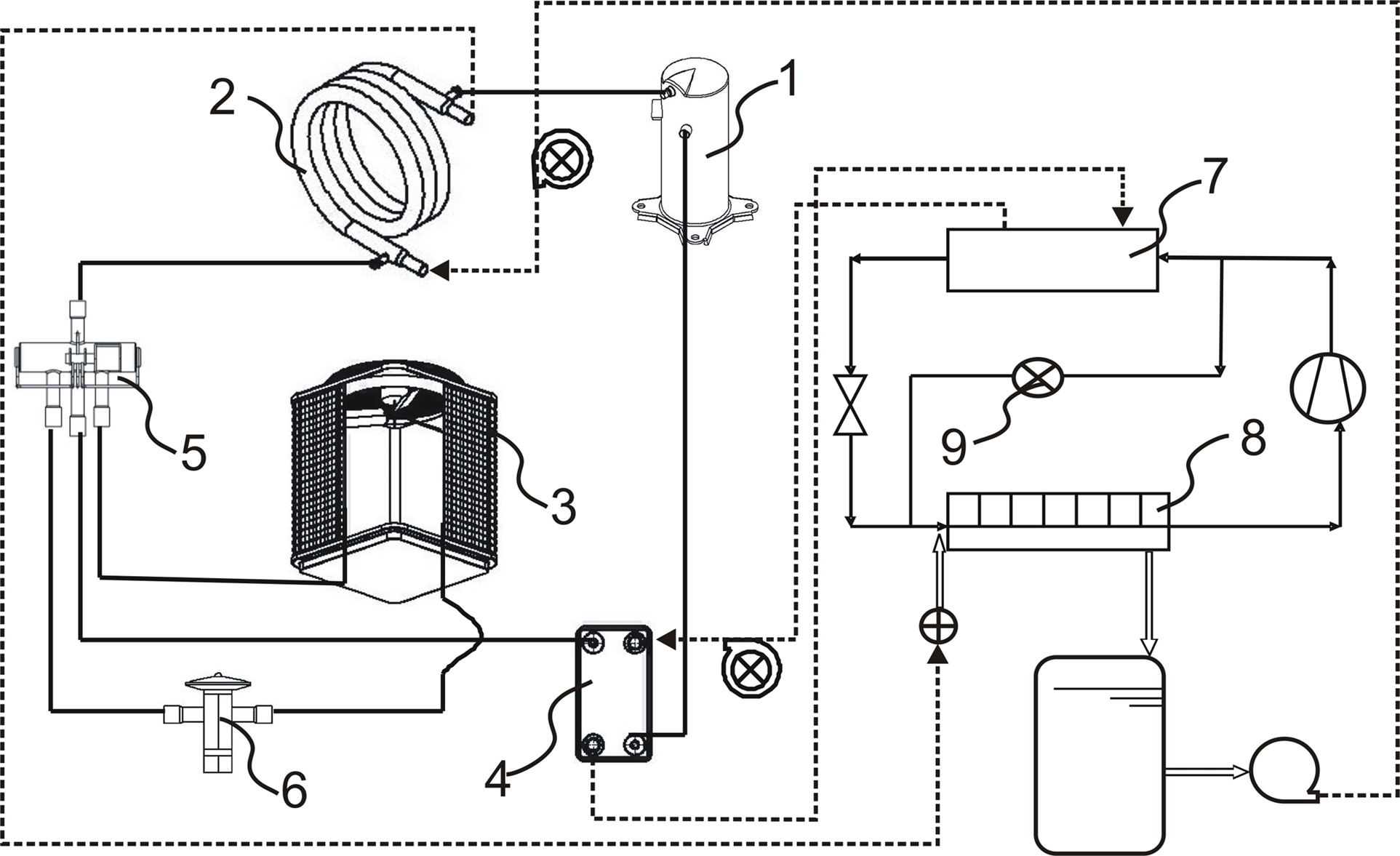

[0012] See attached picture. In this embodiment, 7 is the condenser of the ice machine, 8 is the ice tray of the evaporator of the ice machine, and the refrigerant circulates in the circuit formed between the two, and 9 is a hot gas bypass valve, which transfers the hot gas generated by the condenser 7 Transport to the evaporator ice tray 8 again. In the traditional ice machine, the above-mentioned basically constitutes a complete ice machine, and the ice harvesting mainly relies on the hot gas bypass valve 9; in this embodiment, the hot gas bypass valve 9 only plays the role of assisting the ice harvesting , mainly rely on other parts of the machine.

[0013] This embodiment also has a multi-source load balancing heat pump unit, which includes a compressor 1, three heat exchangers 2, 3, 4, an electromagnetic four-way valve 5 and an expansion valve 6; the heat exchanger 2 is located between the compressor 1 and the electromagnetic Between the inflow ends of the four-way valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com