Ice making machine

An ice making machine and accommodating tank technology, which is applied in the directions of ice making, ice making, lighting and heating equipment, etc., can solve the problems of easy to carry food, unsafe eating, affecting the taste, etc., so as to improve the efficiency of ice making and improve the exchange rate. The effect of the thermal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

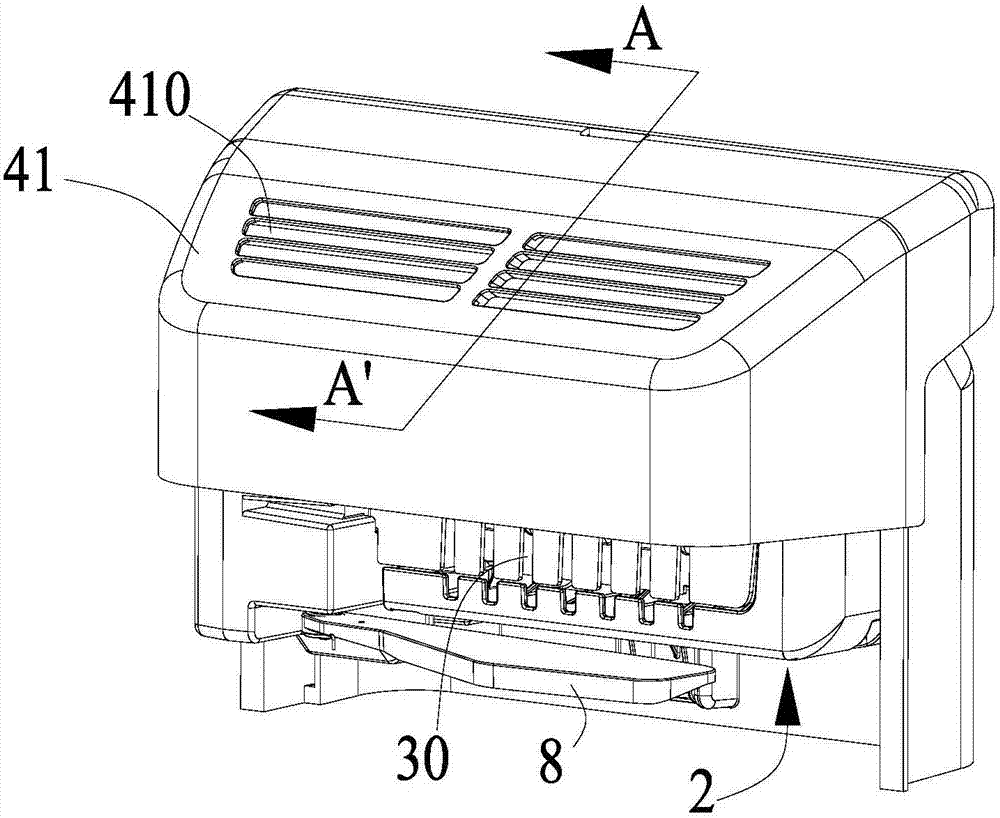

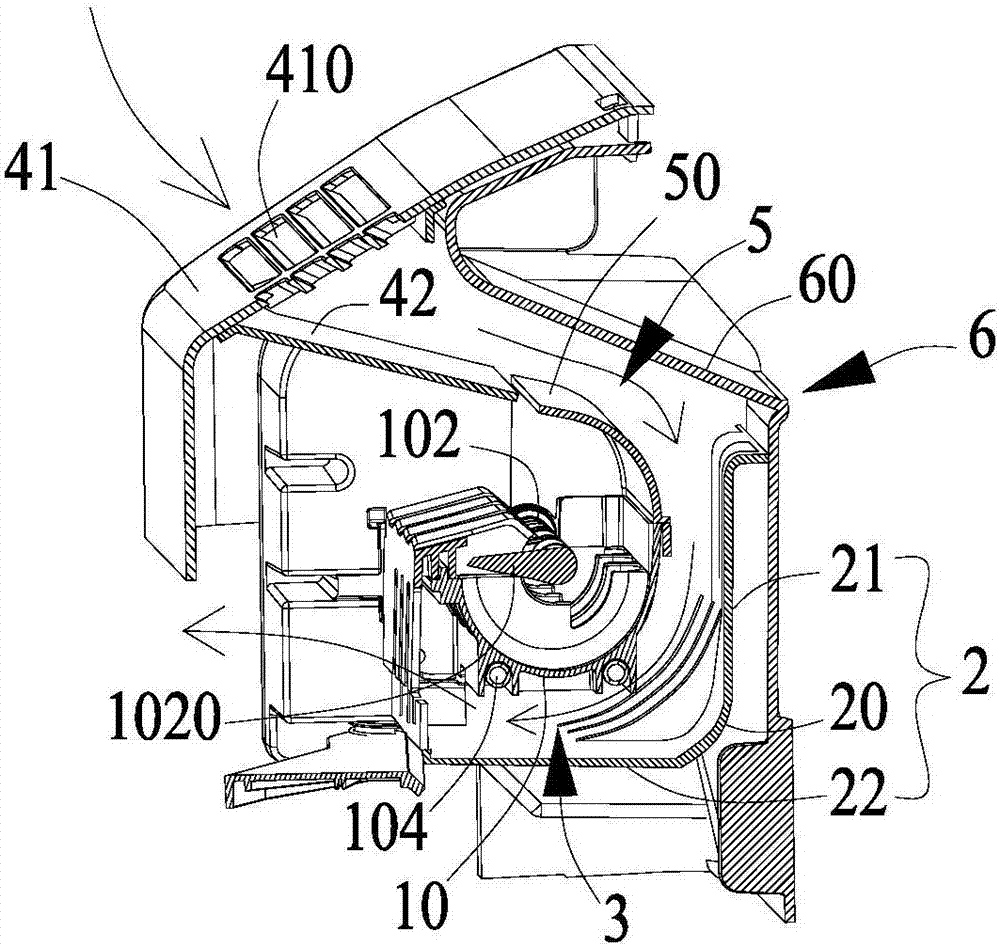

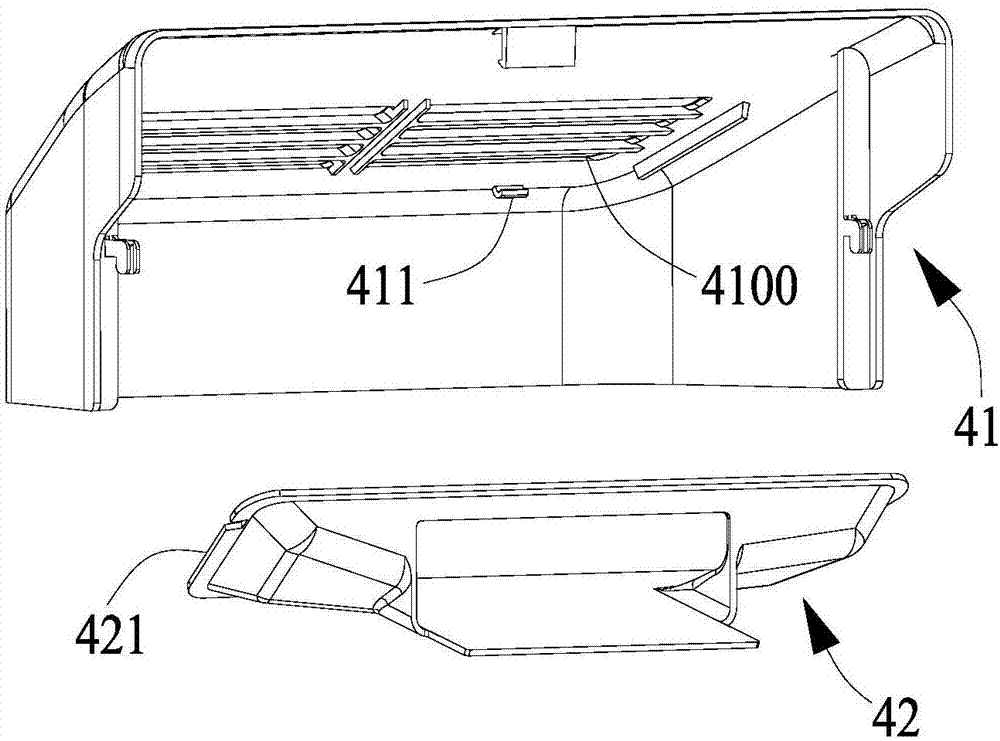

[0022] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings, please refer to Figure 1 to Figure 6 As shown, it is some preferred embodiments of the present invention.

[0023] combine figure 1 , figure 2 , Figure 4 As shown, the ice machine involved in the present invention includes an accommodating tank 10 for accommodating water inside and a cold air cooling assembly that provides cold energy to the accommodating tank 10 to change the water phase into ice. The ice machine also includes a set The wind guide cover 2 on the periphery of the storage tank 10 is interposed between the wind guide cover 2 and the outer wall of the storage tank 10 to form a heat exchange air channel 3 for the cold air to pass through. When the ice maker makes ice, the heat exchange air channel 3 The cold air transfers the cold energy from the outer wall of the accommodating tank 10 to the inside of the accommodating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com