Miniature micro-channel plate-fin heat exchanger

A technology of finned heat exchangers and microchannel plates, which is applied in the field of micro liquid-liquid heat exchangers, can solve problems such as refrigerant leakage, compressive strength lower than 1MPa, and application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

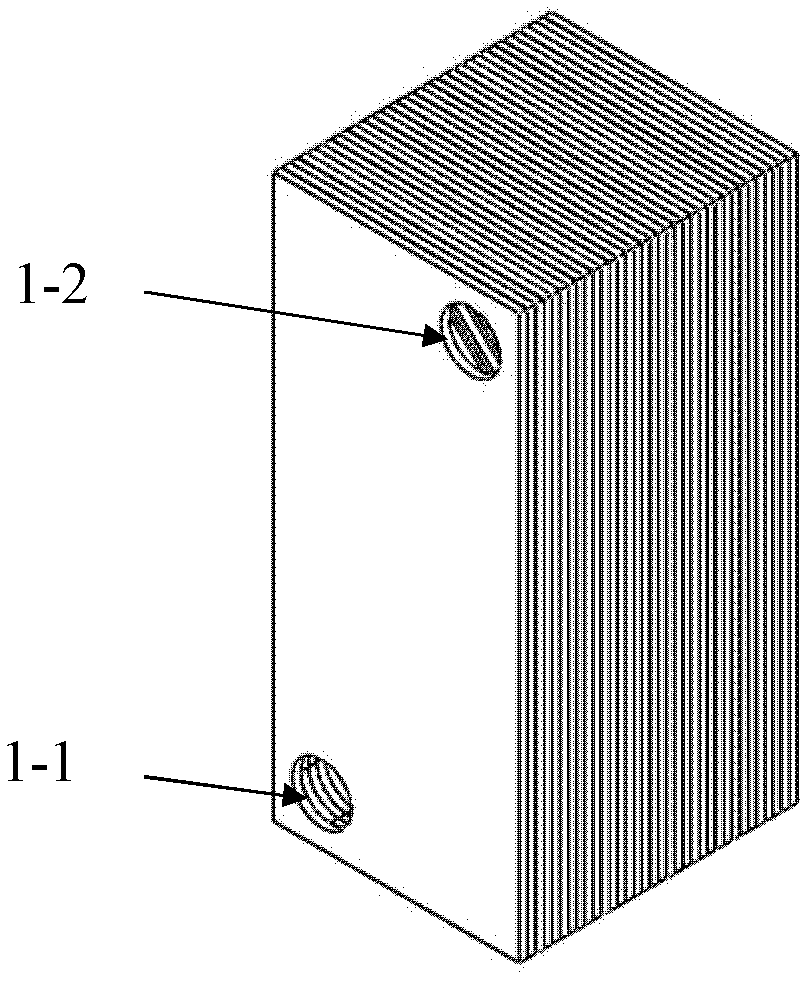

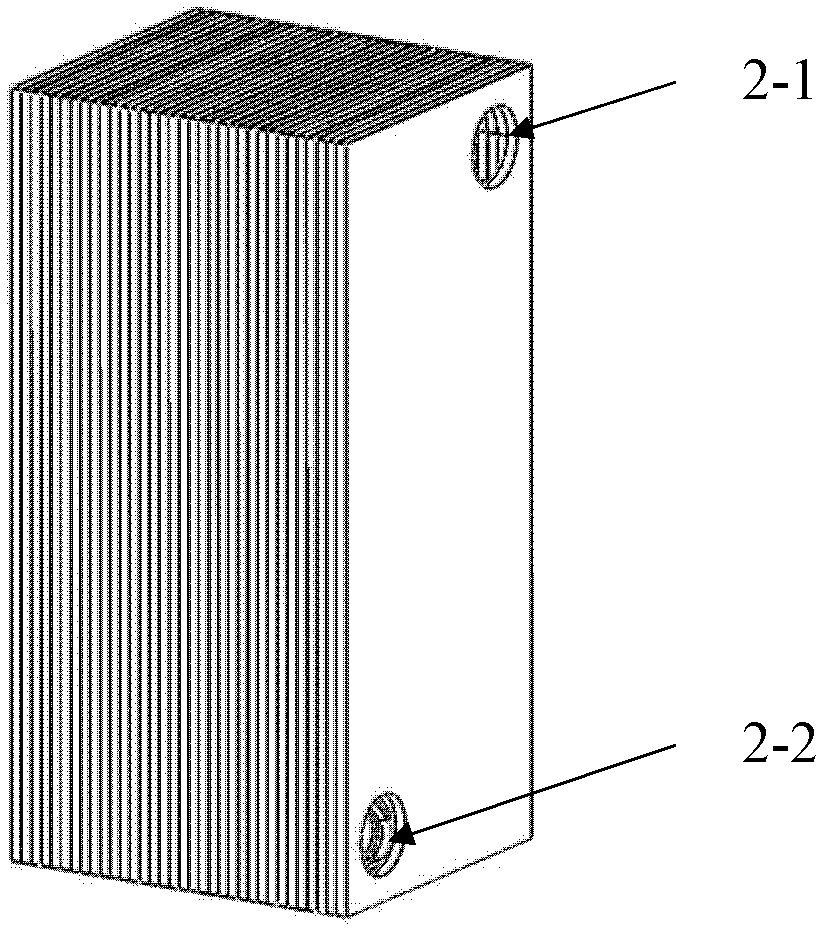

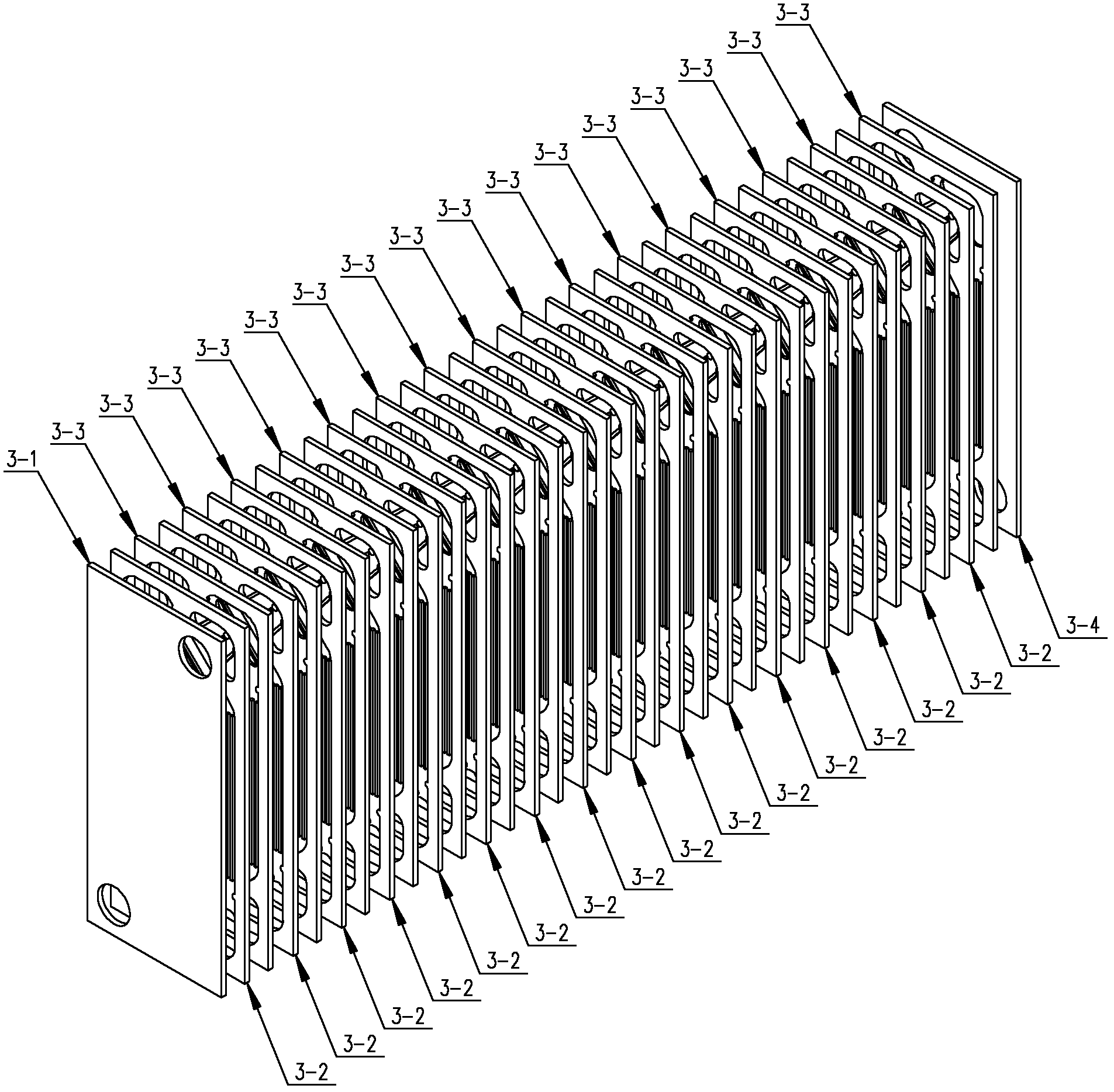

[0021] The present invention provides a novel microchannel plate-fin heat exchanger with compact structure, small size, high heat exchange efficiency and corrosion resistance in order to solve the problem of miniaturization of existing heat exchangers and refrigeration devices.

[0022] The microchannel plate-fin heat exchanger according to an embodiment of the present invention is made of multi-layer metal sheets, and microchannels with a size below 1 mm are formed on each layer of sheets by photochemical etching, and then the sheets with microchannels are stacked. Together, the combination of interlayer molecular level is formed by the method of vacuum hot-pressing diffusion welding, so that all the sheets are connected as a whole, thus forming a complete evaporator.

[0023] According to an embodiment of the present invention, there are four openings on the outer surface of the micro-microchannel plate-fin heat exchanger, which are refrigerant inlet, refrigerant outlet, wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com