Flue gas total-heat recovery device of gas boiler

A gas-fired boiler and total heat recovery technology, applied in air heaters, water heaters, fluid heaters, etc., can solve problems such as restrictions on popularization and development, lower energy efficiency ratio of water heaters, frosting of air source water heater evaporators, etc., to achieve Emission reduction and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

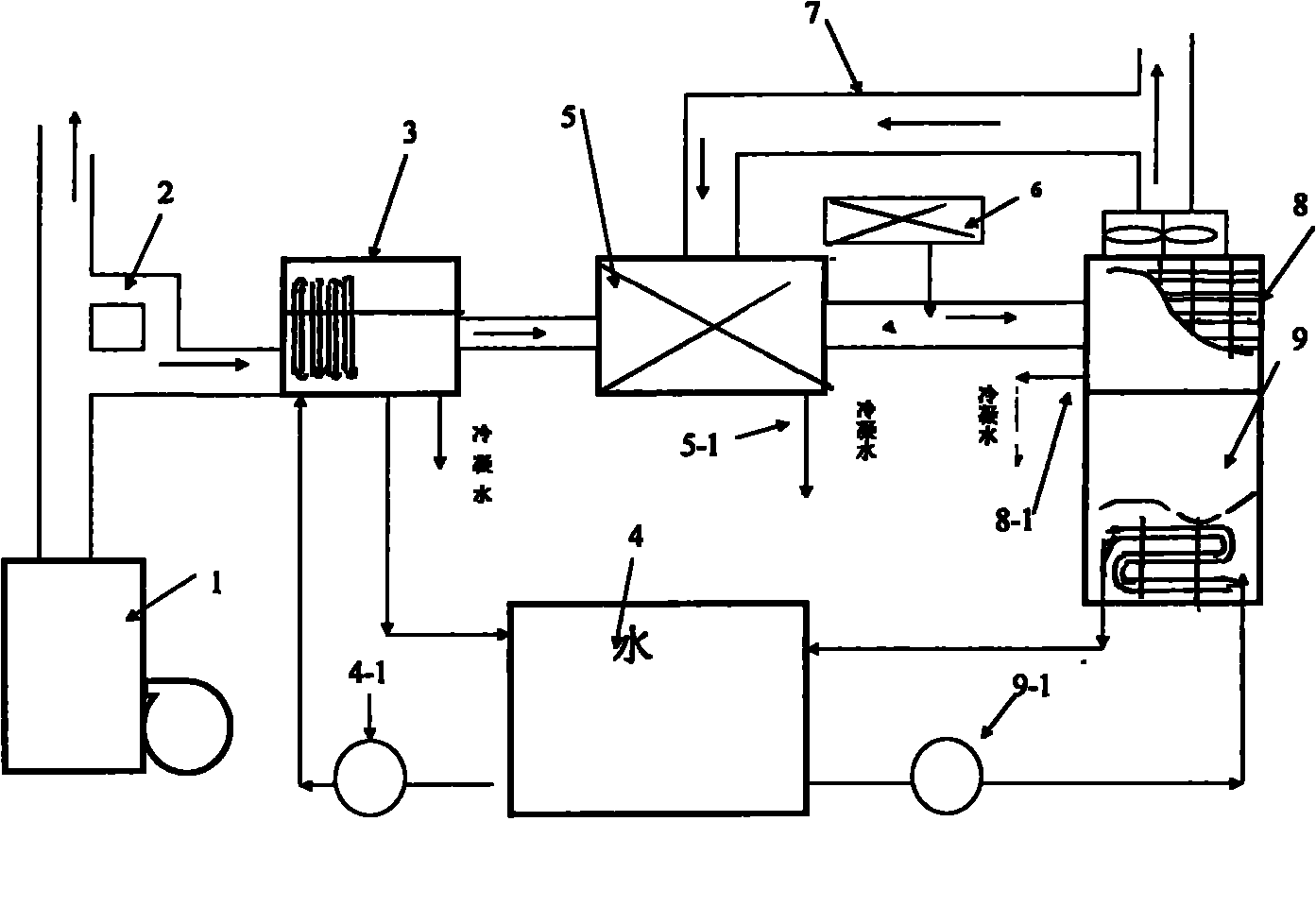

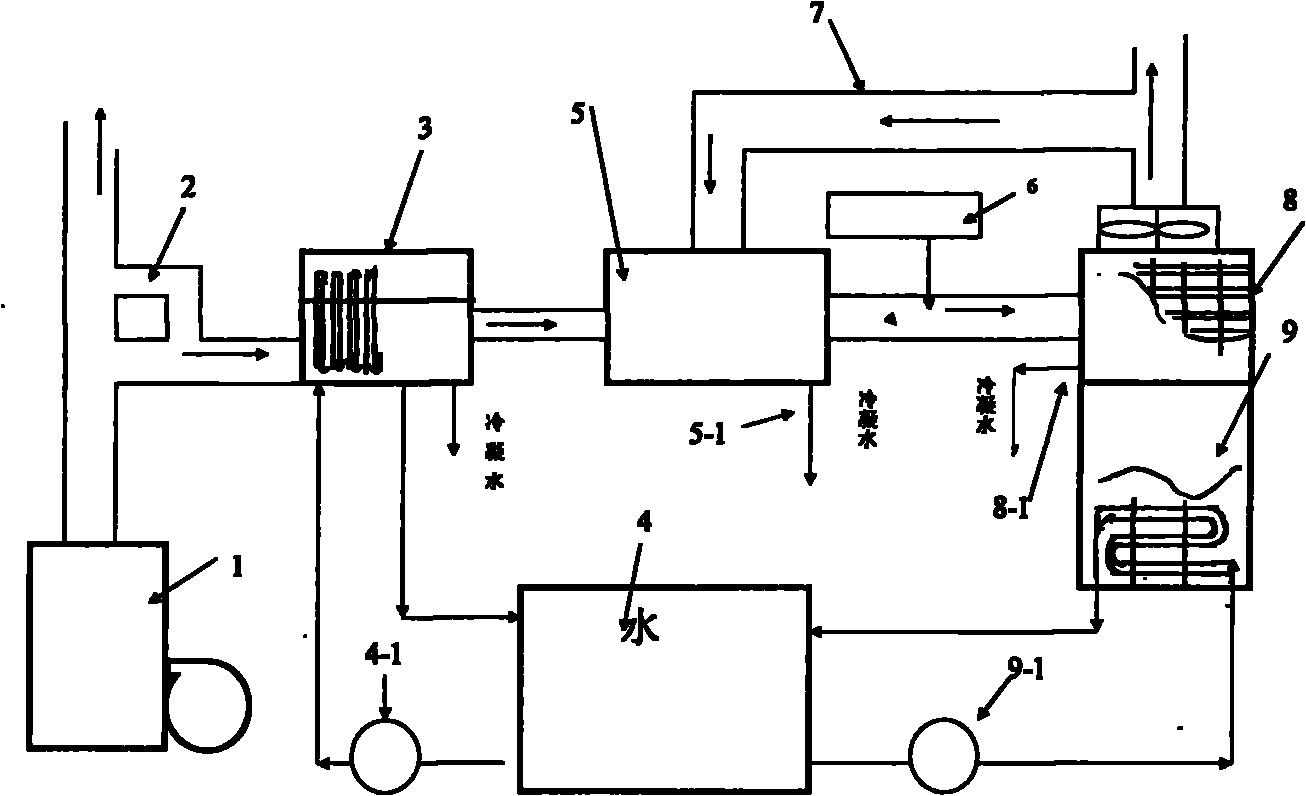

[0012] This embodiment provides a device for generating hot water by performing total heat recovery of flue gas from a gas boiler through a heat exchanger and an air source heat pump, wherein the hybrid cooler is an independent type.

[0013] like figure 1 As shown, the device of this example includes a gas boiler (1), a split flue (2), a gas-water heat exchanger (3), a water tank (4), a mixing desuperheater (5), and a neutralizer dispenser (6). ), return pipeline (7), air source heat pump water heater evaporator (8), air source heat pump water heater (9). It is characterized in that the gas transmission is used between the gas boiler (1), the split flue (2), the gas-water heat exchanger (3), the mixing cooler (5), and the evaporator (8) of the air source heat pump water heater. The pipes are connected to form a closed flow channel. The flue gas of the gas boiler enters the gas-water heat exchanger through the split flue. °C

[0014] The air-water heat exchanger (3) is a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com