Heat treatment process for fine grain austenitic steel pipe bend

An austenitic and fine-grained technology is applied in the field of heat treatment process for fine-grained austenitic steel pipe elbows to achieve the effects of low temperature range, inhibiting grain growth, and improving elbow performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

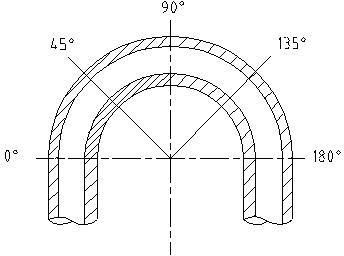

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

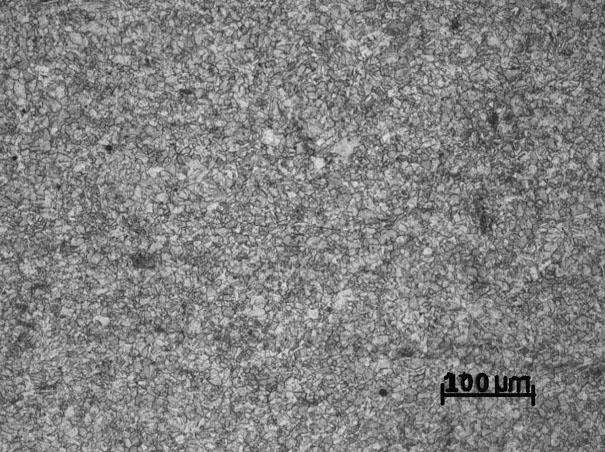

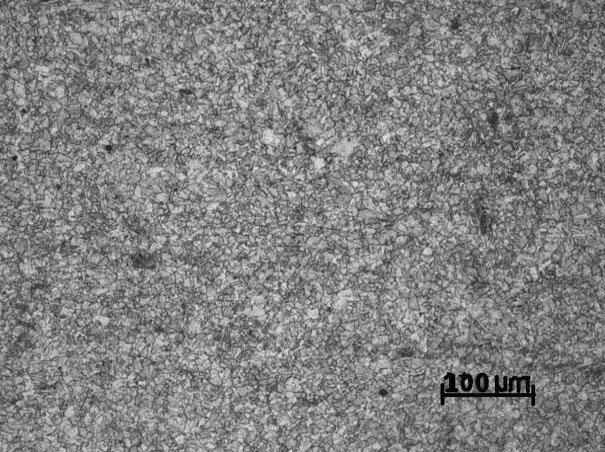

[0018] The heat treatment process for the fine-grained austenitic steel pipe elbow provided by the present invention includes: heat-treating the fine-grained austenitic steel pipe elbow at 900-1050° C. for 2-120 minutes in a heat treatment furnace, and then taking it out of the furnace for cooling , The cooling method adopts air cooling or water cooling.

[0019] The heat treatment temperature adopted in this embodiment is 950° C., heat preservation for 30 minutes, and air cooling.

[0020] The fine-grained austenitic stainless steel elbow used in this example is Super304H austenitic stainless steel, and its chemical composition is shown in Table 1.

[0021] Table 1: Chemical composition (Wt%) of fine-grained austenitic stainless steel elbows.

[0022] chemical element C mn Si S P Cr measured value 0.07 0.64 0.28 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com