Wheel sensor

A wheel sensor and giant magnetoresistive sensor technology, which is applied in railway car body parts, vehicle route interaction equipment, railway signal and safety, etc. and other problems, to achieve the effect of good detection direction, convenient installation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

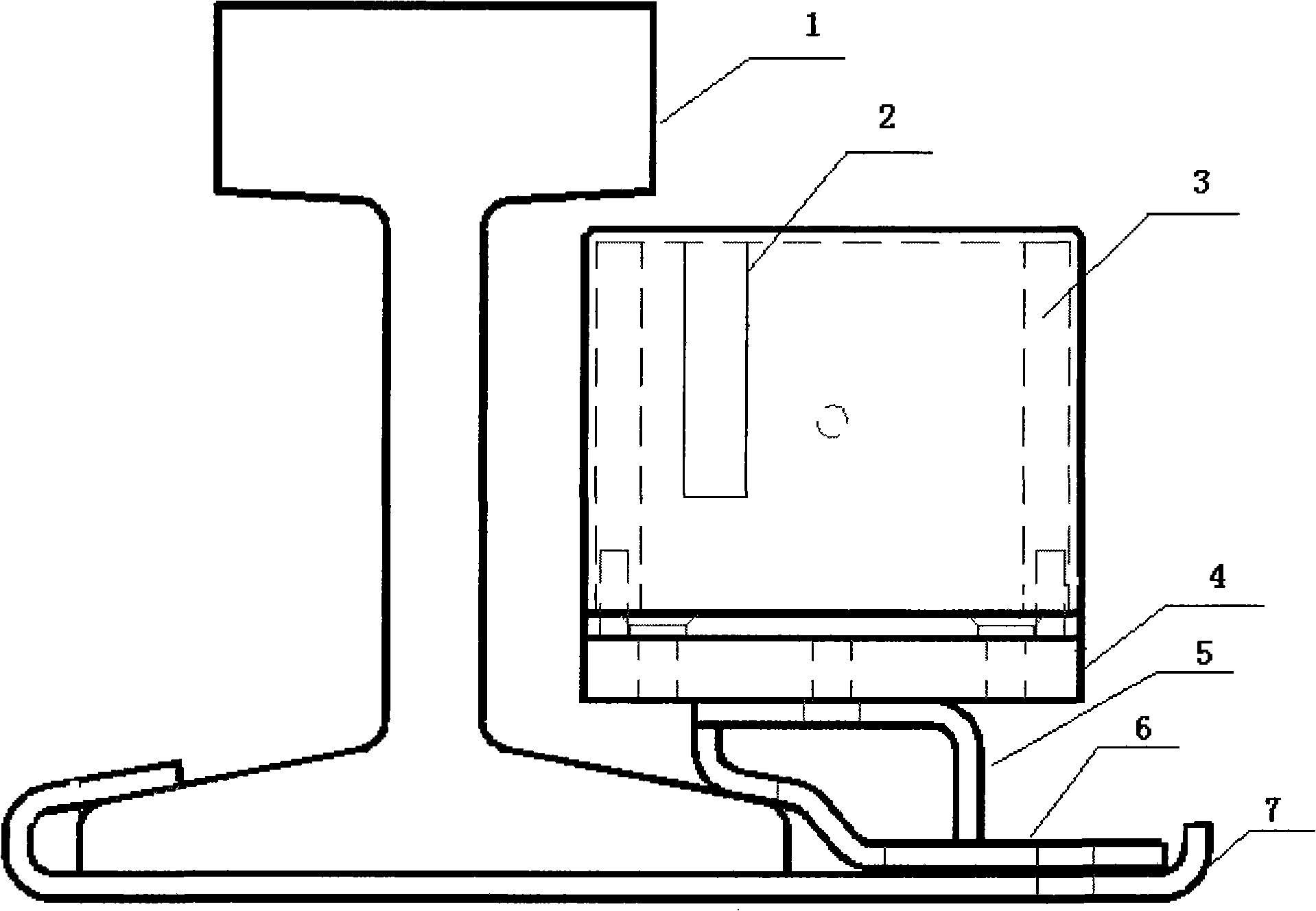

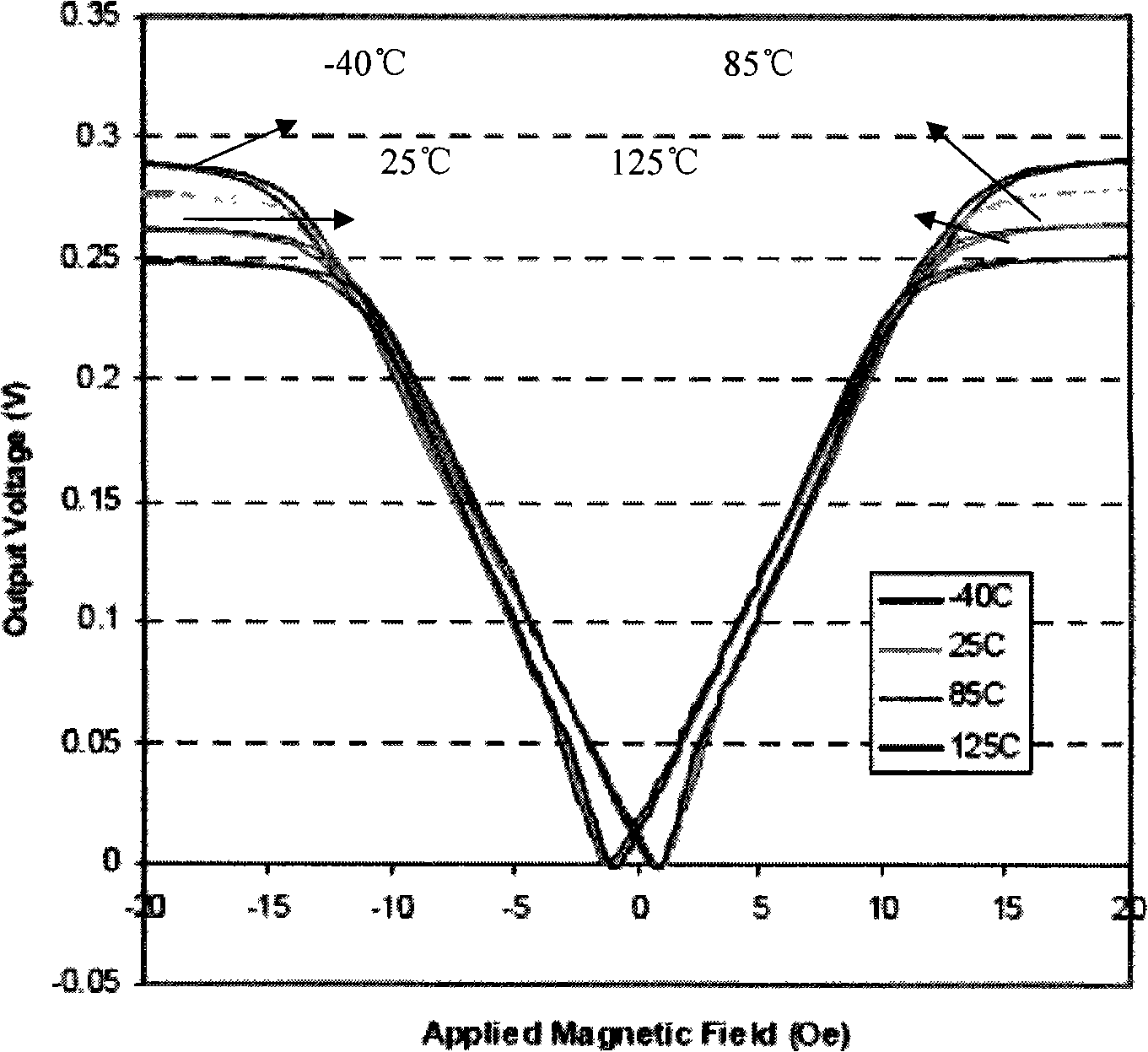

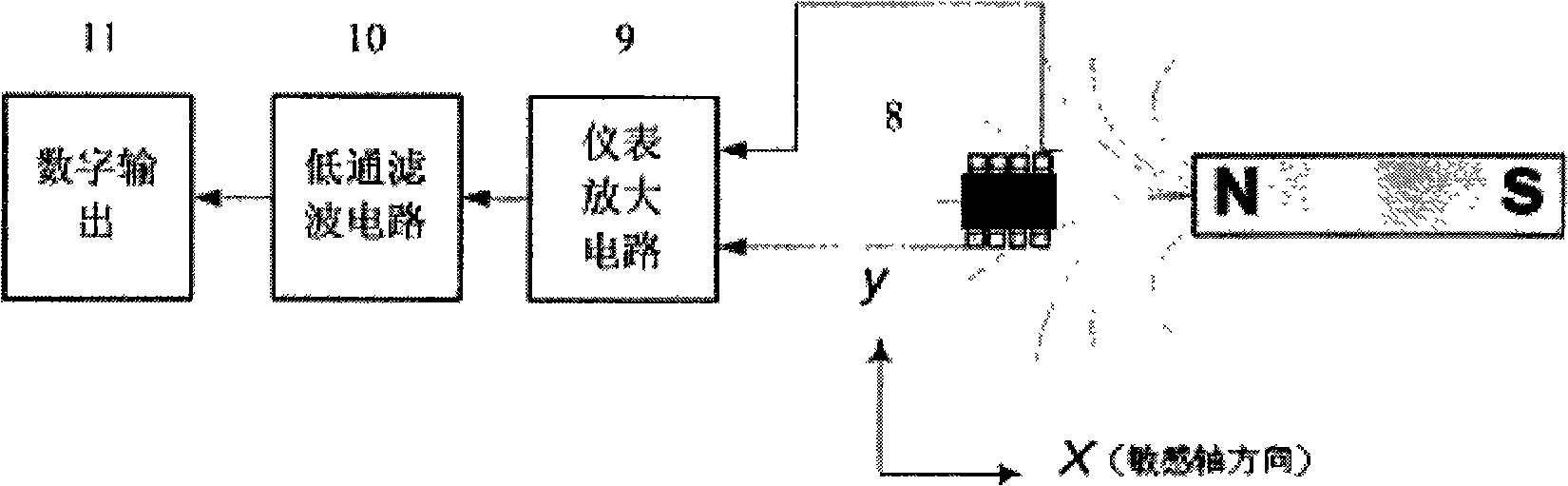

[0019] Embodiment 1: It is used as a wheel sensor. In this embodiment, a giant magnetoresistive chip is used as the core sensing element, and the detection of the wheel is completed in cooperation with the peripheral signal processing circuit. image 3 It is a block diagram of a typical circuit detection principle of a wheel sensor. The giant magnetoresistive sensor includes a bias magnetic field, a giant magnetoresistive chip 8 electrically connected in sequence, an instrument amplifier 9, a digital comparator 10, and a low-pass filter 11. The N pole of the bias magnetic field corresponds to Giant magnetoresistive chip 8 is arranged, and instrument amplifier 9 adopts AD620 instrument amplifier in the present embodiment, and low-pass filter 11 adopts active second-order low-pass filter, and when the external magnetic field changes, the resistance of Wheatstone bridge changes. The weak signal output by the bridge is sent to the AD620 instrumentation amplifier, filtered by an act...

Embodiment 2

[0020] Embodiment 2: Used as an axle counting sensor. In the application of this embodiment, two giant magnetoresistive sensors are used as a group, and the microprocessor 14 is used as an axle counting sensor. The circuit diagram of the system is as follows: Figure 4 As shown, the two sensors are respectively connected to the interrupt I / O ports of the microprocessor 14, and the direction of the train is judged according to the time sequence when the I / O port of the microprocessor 14 enters the interrupt. Cooperating with the microprocessor, the sensor has the ability to identify the vehicle type, and can judge whether the vehicle or the locomotive passes above the sensor. In this embodiment, when the axle counting device is connected to the microprocessor, it may also be one or more sensors. The housing of the sensor is made of aluminum material, which improves the stability of the whole system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com