Compact counterflow heat exchanger

a heat exchanger and counterflow technology, applied in the field of heat exchangers, can solve the problems of weld splatter, distortion of thin sheet metal fins, and unreliable production of compact micro-channel heat exchangers b>10/b> using micro-channel flow passages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

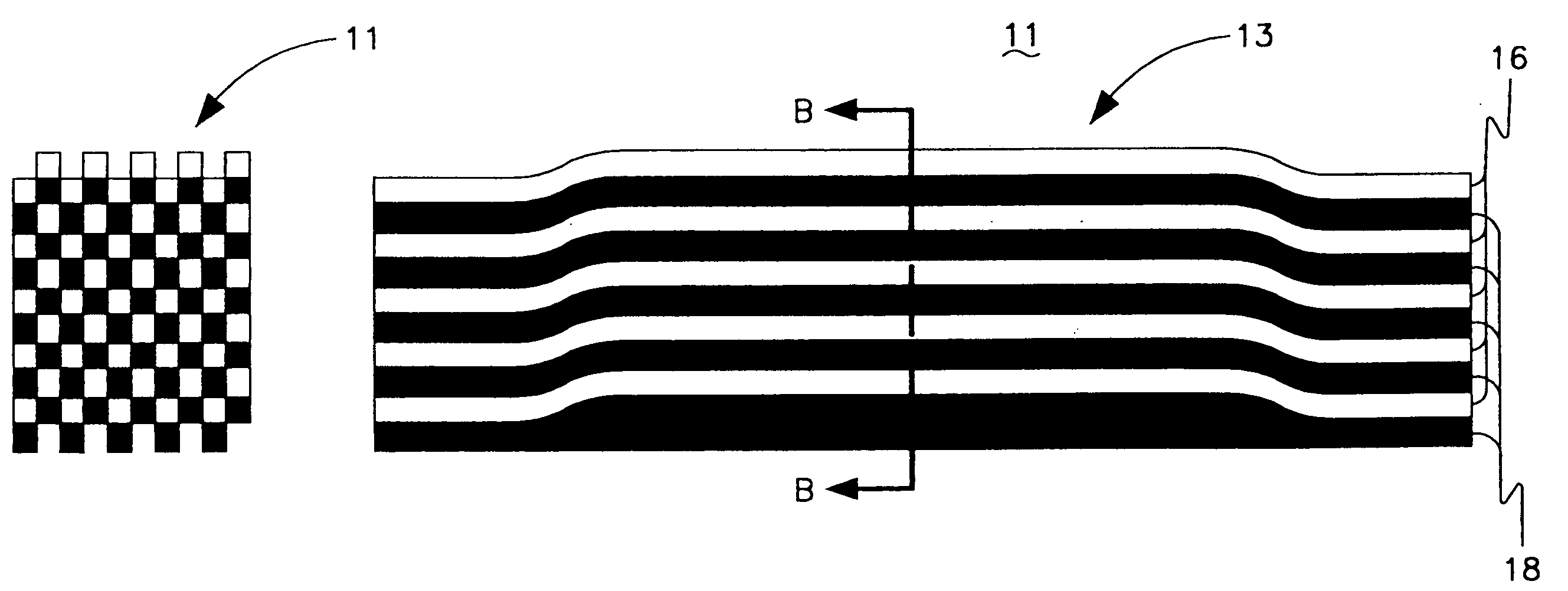

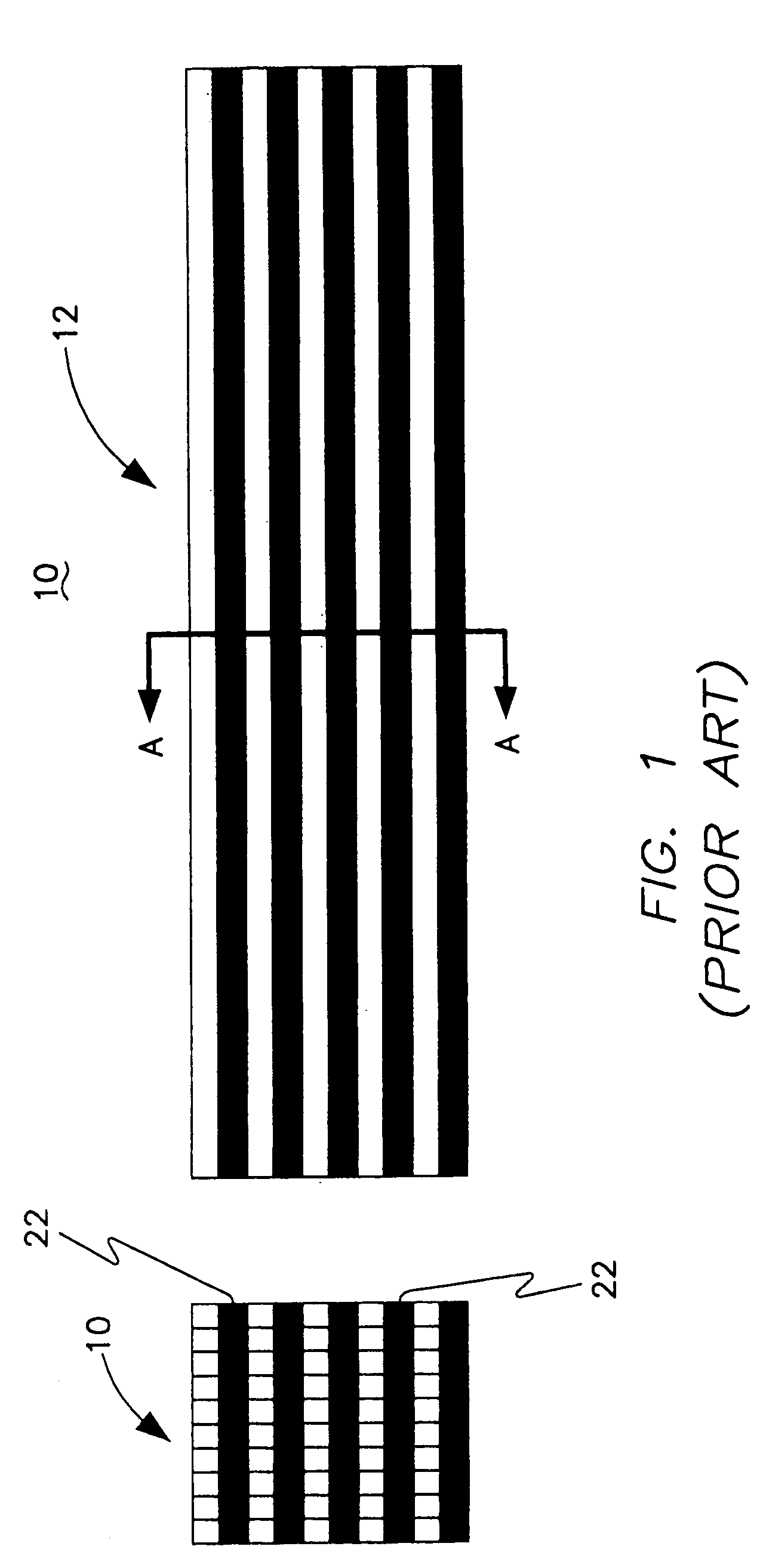

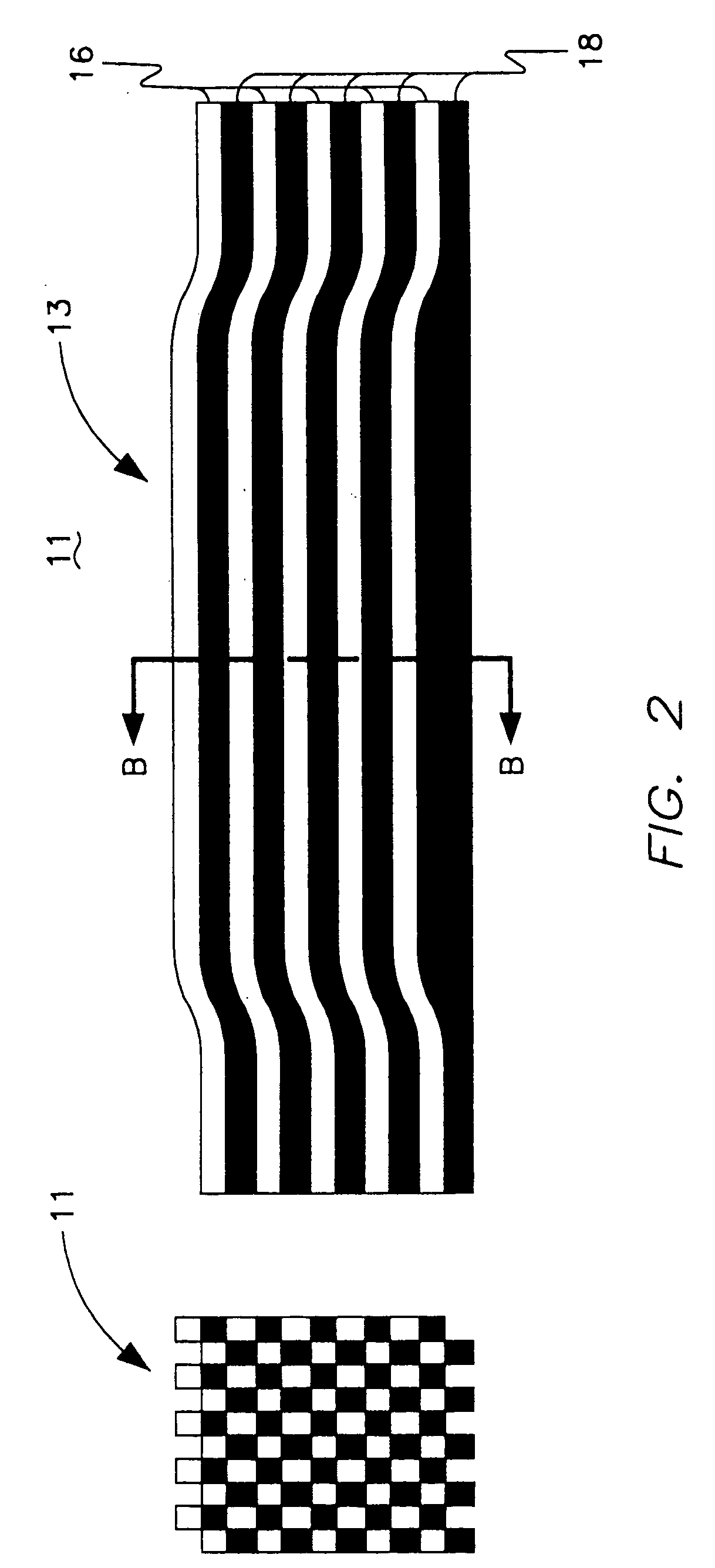

[0014]FIG. 1 shows a typical baseline heat transfer arrangement comprising a heat exchange core assembly 10 of square-formed seamless channels 16, and an identical square formed seamless counterflow channel 18. The channels 16, 18 each have multiple square tubes 12 of equal dimensions, 10 and arranged in parallel configuration.

[0015] Onto the substrate layer 22 are added seriatim multiple layers of the tubes 12, each provided with a particular geometric feature. The tubes 12 are stacked in a vertical plane and arranged adjacent to each other and the substrate layer 22. In other words, tube 12 comprising the channel 16, 18 or the assembly 10 are arranged, or “stacked”, in ascending and descending column-like channels, both above and below one another, in an alternating checkerboard pattern, as shown in section A-A.

[0016] In preparing the core assembly 10, each one of the tubes 12 forming channels 16, 18 is made of a suitable material having desired heat transfer characteristics, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com