Additional reductant-free smoke denitration device and method for combustion equipment

A technology of combustion equipment and reducing agent, which is applied in the direction of separation methods, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of air preheater and other equipment such as corrosion, unsafety, and high denitrification cost, so as to reduce operating costs and improve Safety, benefit and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

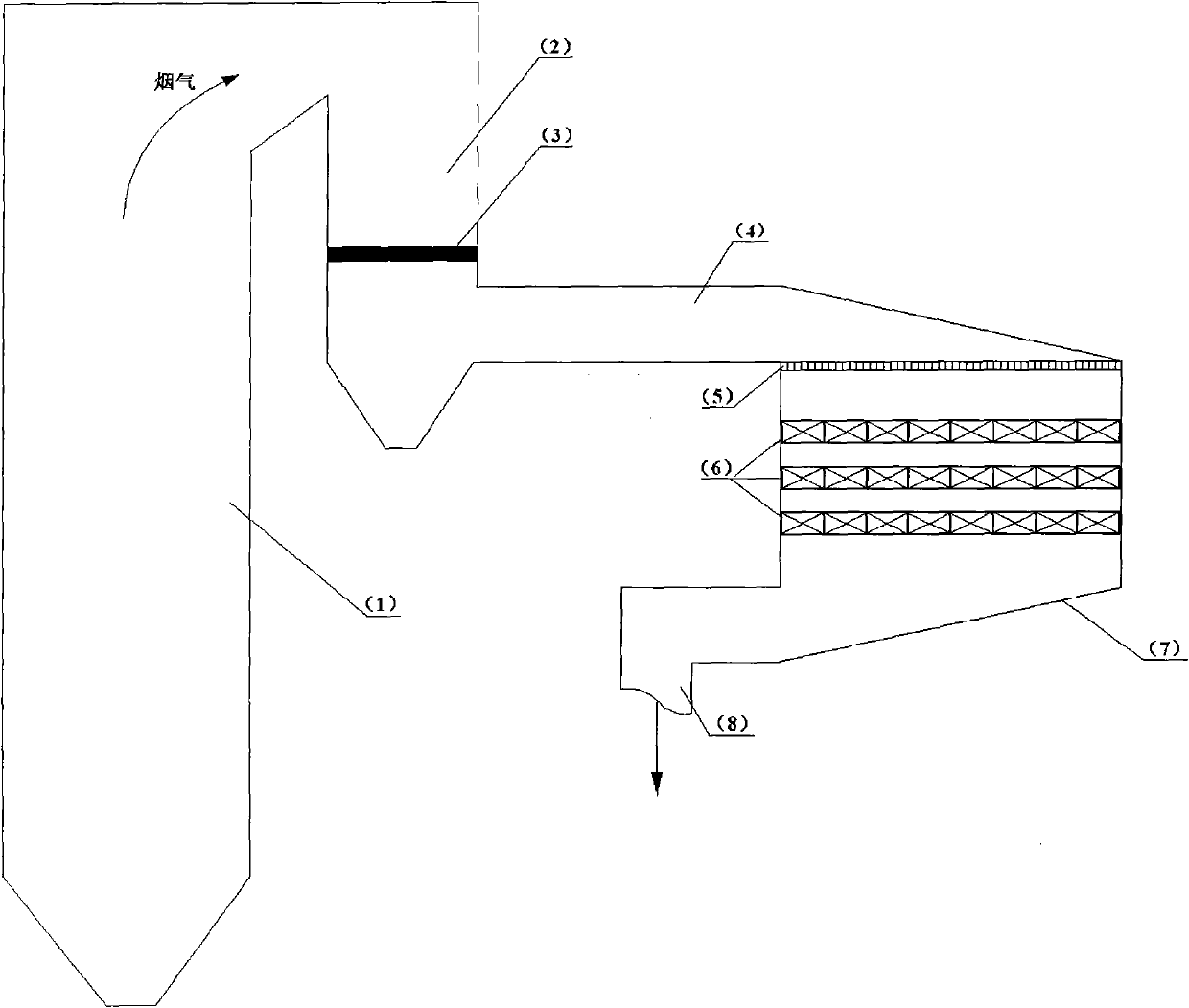

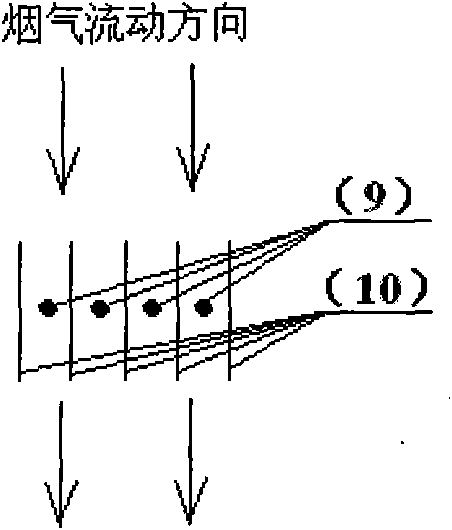

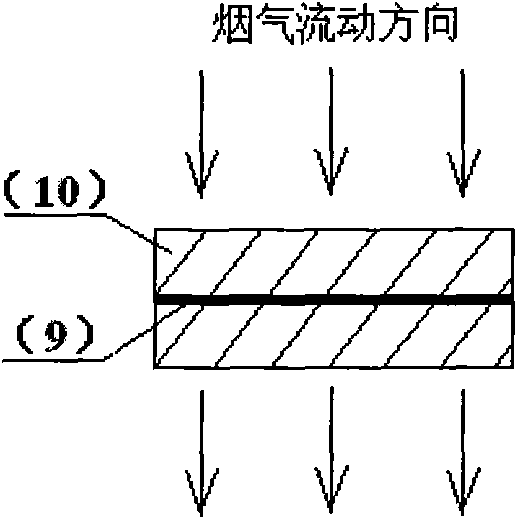

[0020] Such as figure 1 As shown, a flue gas denitrification device for combustion equipment without additional reducing agent is: the combustion equipment includes a connected boiler 1 and an economizer 2, and a discharge device 3 is arranged in the economizer 2, and the economizer 2. The inlet of the denitration reactor is connected to the flue 4, the rectification device 5, the catalyst bed 6, the denitration reactor 7, and the outlet of the denitration reactor to the flue 8, which are connected in sequence, and the denitration reactor 7 is provided with a catalyst bed 6.

[0021] Such as image 3 As shown, the flue gas denitrification device for combustion equipment without additional reducing agent, the combustion equipment includes a connected boiler 1 and an economizer 2, which is characterized in that: the economizer 2, the inlet of the denitration reactor is connected to the flue 4, Rectification device 5, catalyst bed 6, denitrification reactor 7, denitrification re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com