Biomass gasification boiler using air-steam as gasifying agent and coupling combustion method thereof

A gasification boiler and steam technology, applied in the field of boiler combustion, can solve the problems of easy slagging, low thermal efficiency, and high tar content, and achieve the effects of reducing fly ash, improving conversion efficiency, and improving gasification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

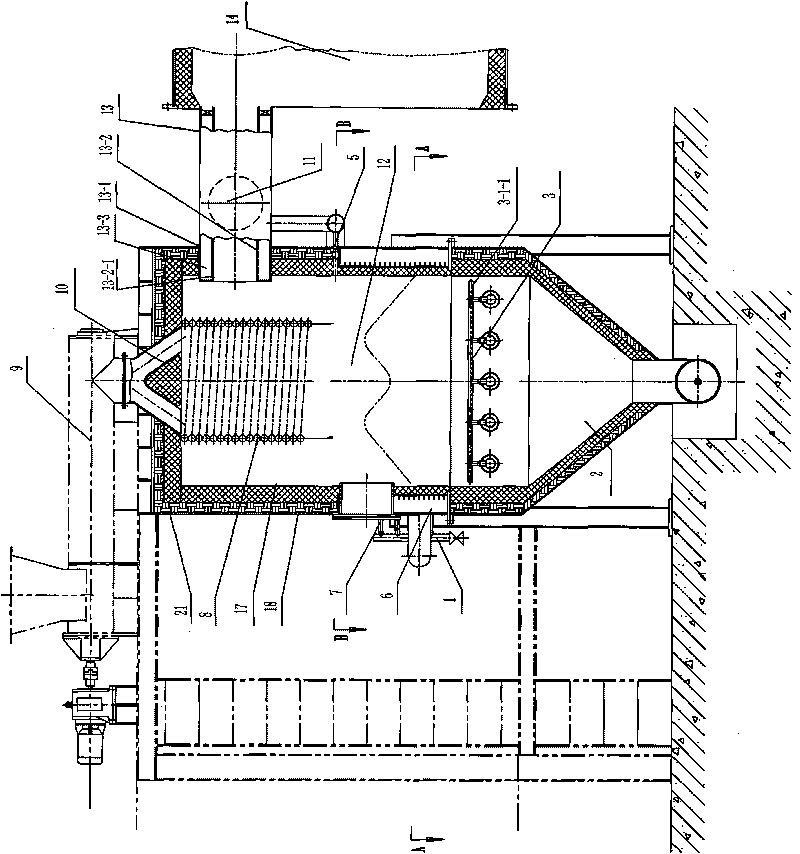

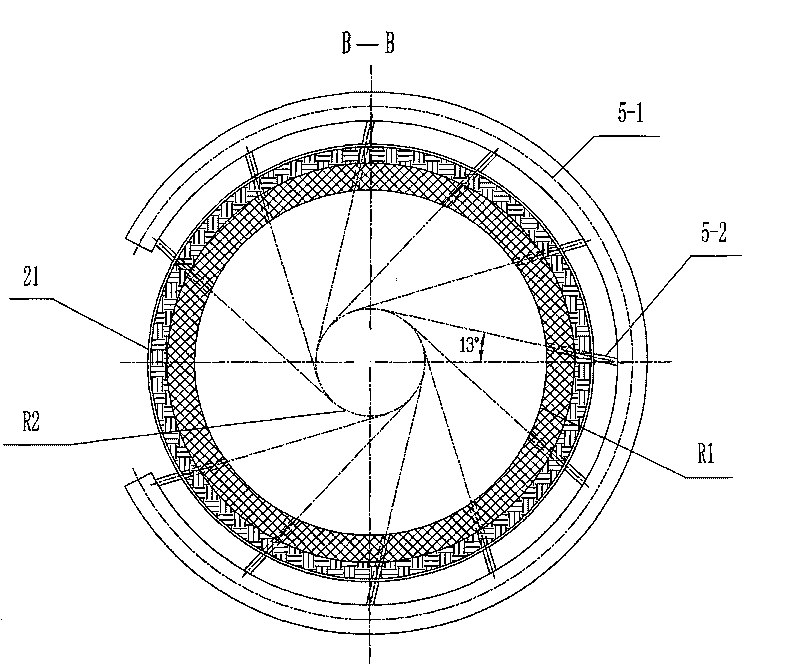

[0016] Specific implementation mode two: as Figure 1~4 As shown, the central axes of the plurality of tangential nozzles 5-2 in this embodiment are tangent to the concentric imaginary circle R2 whose radius is 1 / 4 to 1 / 3 of the cross-section circle R1 of the inner wall of the furnace. Such setting can make the powdery biomass material burn more fully. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: as Figure 4 As shown, the biomass gasification boiler in this embodiment further includes a spiral slagging machine 15, and the spiral slagging machine 15 is arranged on the furnace body below the ash chamber 2. The spiral slagging machine is a component in the prior art. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0018] Specific implementation mode four: as Figure 4 As shown, the biomass gasification boiler in this embodiment further includes a vibrating ash loosening device 16 , and the vibrating ash loosening device 16 is installed on the edge of the fire grate 3 and is located outside the furnace body 21 . Vibrating the ash loosener 16 is a component in the prior art. Other components and connections are the same as those in the third embodiment.

specific Embodiment approach 5

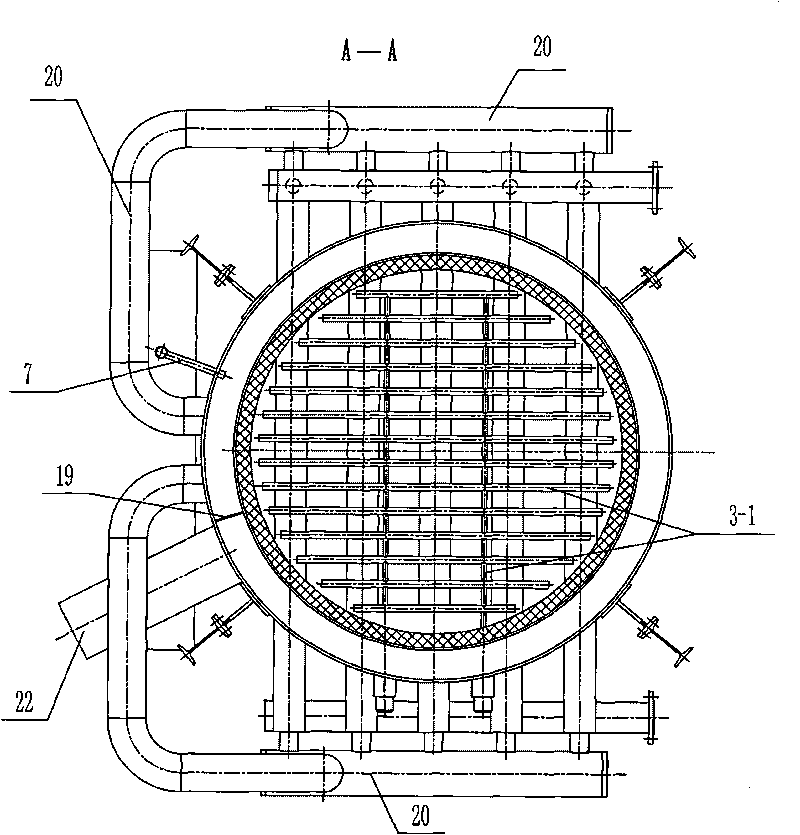

[0019] Specific embodiment five: the coupled combustion method of the biomass gasification boiler using air water vapor as the gasification agent described in this embodiment is realized according to the following steps: Step 1, using screw feeder 9 to feed the biomass After the fuel is sent into the gasification combustion chamber 12, it is in a suspended state, and the temperature of the gasification combustion chamber 12 is controlled below 600°C; Step 2: Use the heat generated in the gasification combustion chamber 12 to heat the air and atomize the fine particles The water mist is gasified into water vapor, and then the hot air and water vapor are mixed and sprayed into the gasification combustion chamber 12 from the nozzle hole at the bottom of the grate 3 as a gasification agent. The hot air in the gasification agent is primary air; The upper gasification combustor 12 provides tangential secondary air supply; fully converts the biomass into combustible gases: hydrogen an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com