Method for harmlessly recycling sludge

A recycling and sludge technology, which is applied in the direction of chemical instruments and methods, combustion methods, sludge treatment, etc., can solve the problems of low incineration heat energy recovery, high management requirements, and large infrastructure investment, so as to achieve small investment and avoid secondary Effects of pollution and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

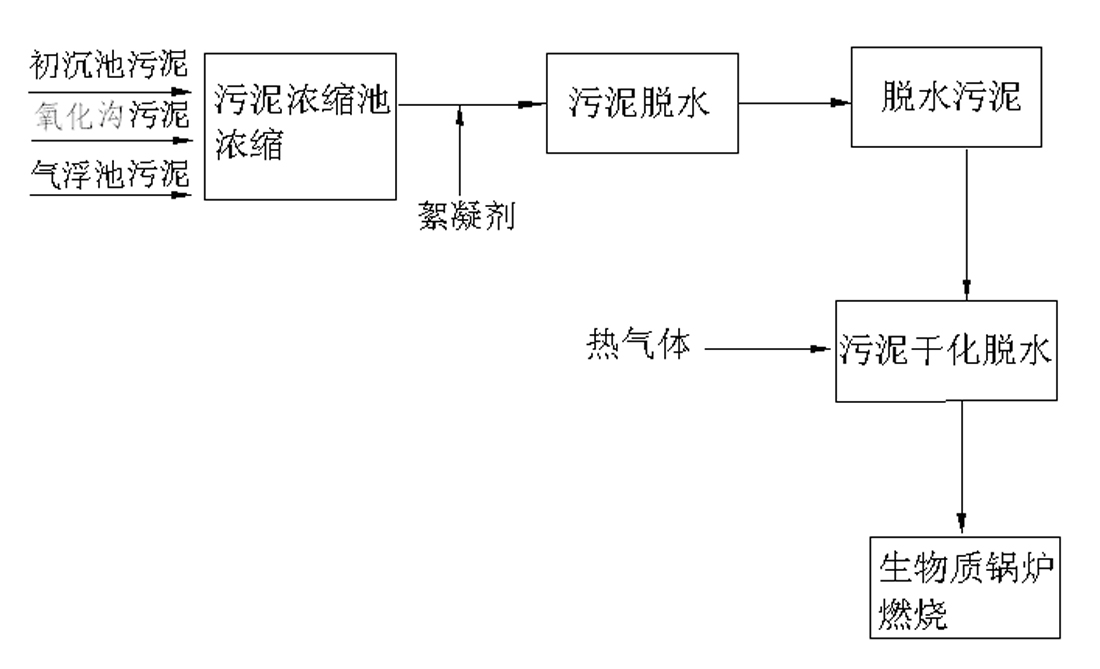

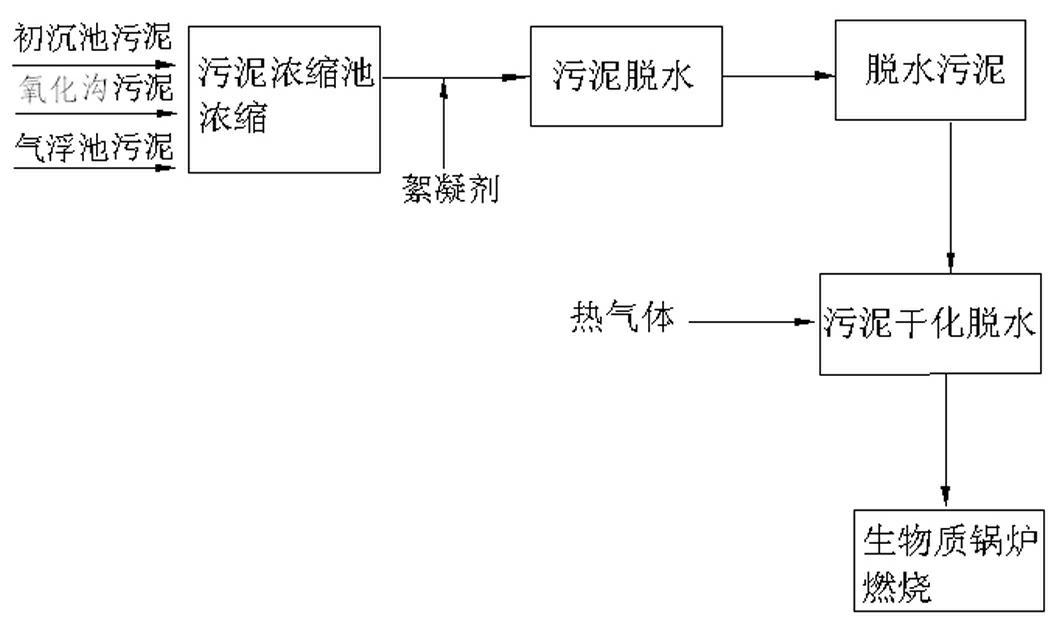

Method used

Image

Examples

Embodiment 1

[0022] The mixed sludge from the primary sedimentation tank, oxidation ditch and advanced treatment air flotation tank with a moisture content of 98.5% enters the sludge concentration tank, and the sludge is concentrated to a moisture content of 94% through the sludge concentration tank; the sludge concentration tank has a moisture content of 94% The sludge is transported to the belt sludge dehydrator for dehydration treatment through pipelines. In the sludge conveying pipeline, the 3Add 25g of polyacrylamide flocculant to the sludge, and the water content of the dehydrated sludge will drop to 75%; the sludge with a water content of 75% will be sent to the sludge screw press for drying and dehydration treatment, and at the same time, it will be sent to the sludge screw press The hollow cavity of the screw blade of the press is fed with lime kiln flue gas at a temperature of 220°C. The moisture content of the sludge gradually decreases to 57% under the action of continuous compr...

Embodiment 2

[0024] The mixed sludge from the primary sedimentation tank, oxidation ditch and advanced treatment air flotation tank with a moisture content of 99% enters the sludge concentration tank, and the sludge is concentrated to a moisture content of 95% through the sludge concentration tank; the sludge concentration tank has a moisture content of 95% The sludge is transported to the belt sludge dehydrator for dehydration treatment through pipelines. In the sludge conveying pipeline, the 3 Add 20g of polyacrylamide flocculant to the sludge, and the water content of the dehydrated sludge will drop to 80%; the sludge with a water content of 80% will be sent to the sludge screw press for drying and dehydration treatment, and at the same time, it will be sent to the sludge screw press The hollow cavity of the screw blade of the press is fed with lime kiln flue gas at a temperature of 200°C. The moisture content of the sludge gradually decreases to 59% under the action of continuous compr...

Embodiment 3

[0026] The mixed sludge from the primary sedimentation tank, oxidation ditch and advanced treatment air flotation tank with a moisture content of 99.5% enters the sludge concentration tank, and the sludge is concentrated to a moisture content of 96% through the sludge concentration tank; the sludge concentration tank has a moisture content of 96% The sludge is transported to the belt sludge dehydrator for dehydration treatment through pipelines. In the sludge conveying pipeline, the 3 Add 35g of polyacrylamide flocculant to the sludge, and the water content of the dehydrated sludge will drop to 85%; the sludge with a water content of 85% will be sent to the sludge screw press for drying and dehydration treatment, and at the same time, it will be sent to the sludge screw press The hollow cavity of the screw blade of the press is fed with lime kiln flue gas at a temperature of 180°C. The moisture content of the sludge gradually decreases to 60% under the action of continuous com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com