Biomass boiler

A technology of biomass boilers and biomass fuels, which is applied in the configuration of valves, combustion methods, fluid heaters, etc., can solve the problems of low heat absorption efficiency, achieve high heating efficiency, avoid heat dissipation and burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

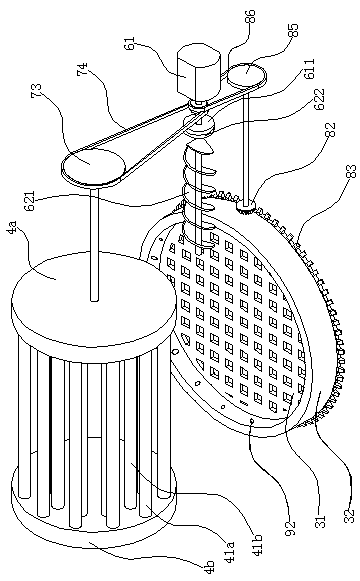

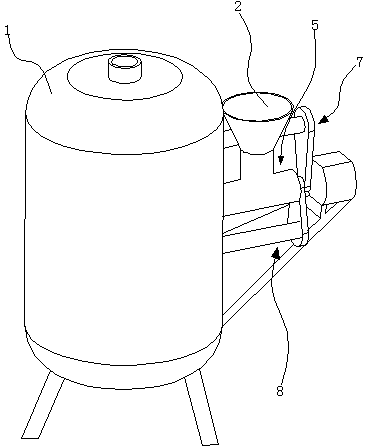

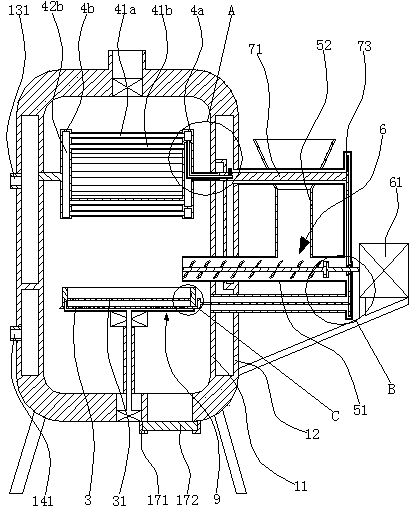

[0031] Such as figure 1 as shown, figure 2 , image 3 As shown, a biomass boiler includes a furnace body 1 and a material storage basin 2. The furnace body 1 is cylindrical in shape, has a bracket at the bottom, and is erected on the ground. Pot 2 is used to place biomass fuel. The furnace body 1 includes an inner layer 11 and an outer layer 12. An upper water storage chamber 13 and a lower water storage chamber 14 are formed between the inner layer 11 and the outer layer 12. Both the upper water storage chamber 13 and the lower water storage chamber 14 surround the furnace body 1. One week, the two are separated by a heat insulating layer. The upper water storage chamber 13 is provided with a water inlet 131, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com