Biomass low-nitrogen direct combustion boiler

A biomass and low-nitrogen technology, applied in the direction of combustion methods, combustion equipment, solid fuel combustion, etc., can solve the problems of combustible gas not easy to burn out, low ignition point, high volatile content of biomass fuel, etc., to avoid gas incompleteness Combustion loss, suppression of NOx generation, and improvement of boiler thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

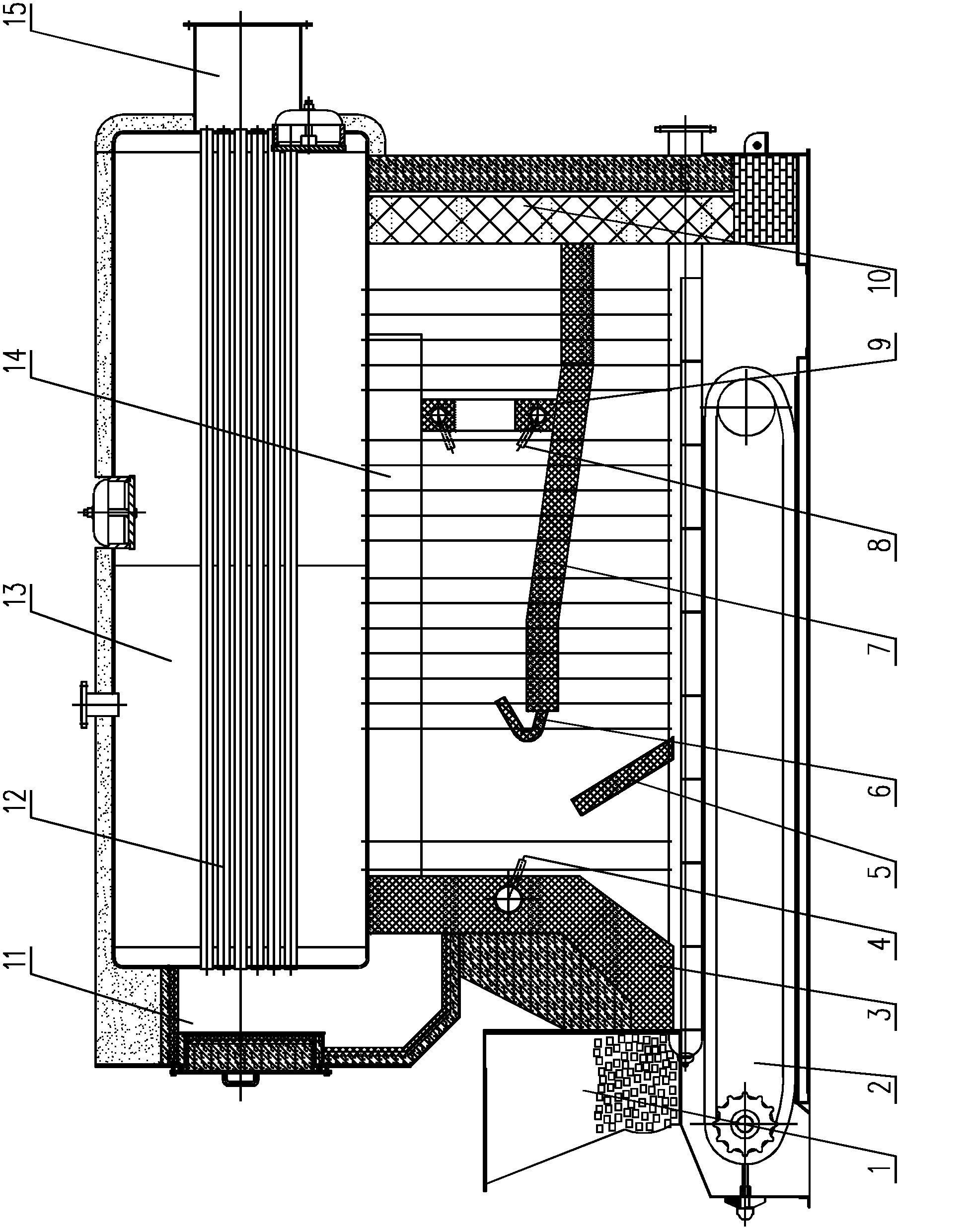

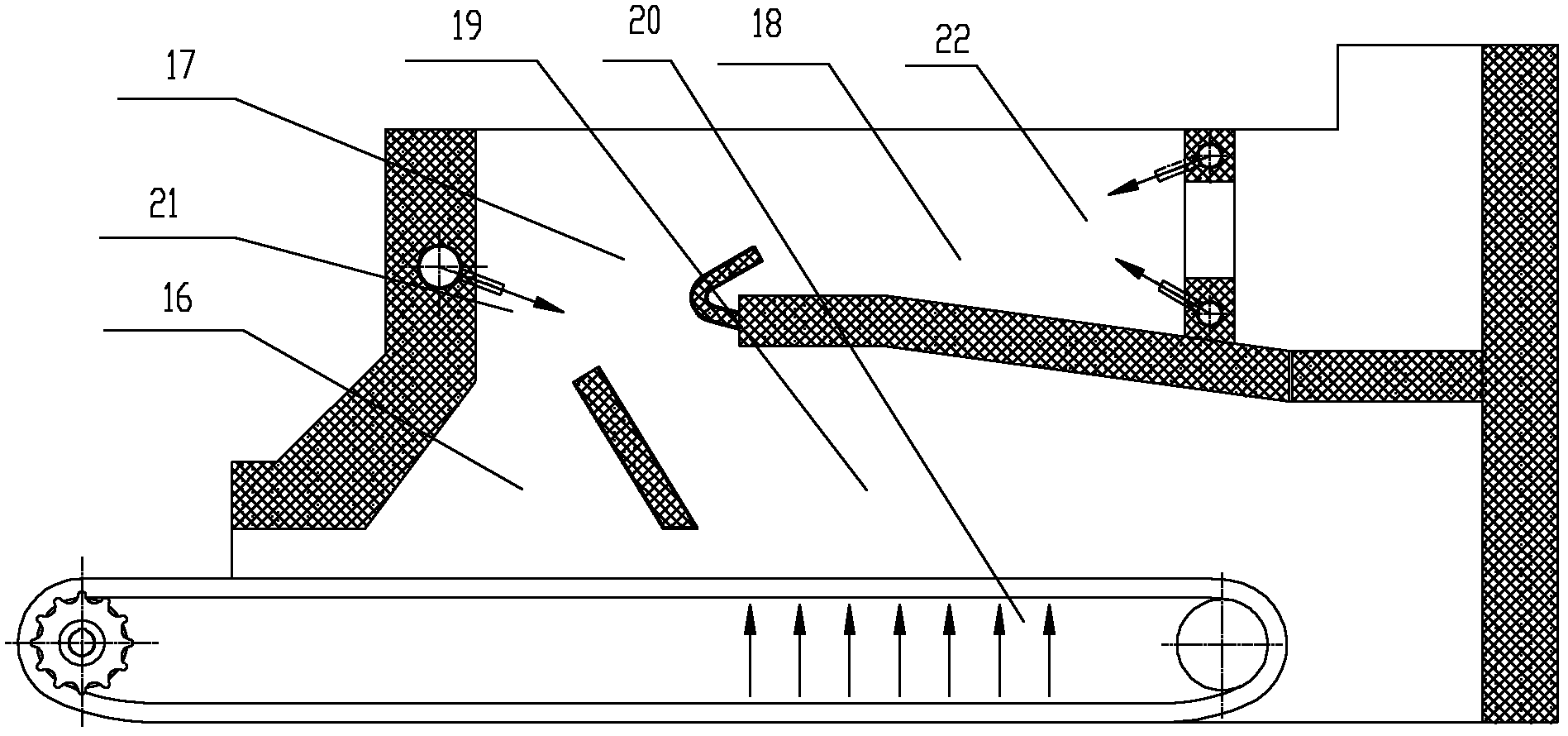

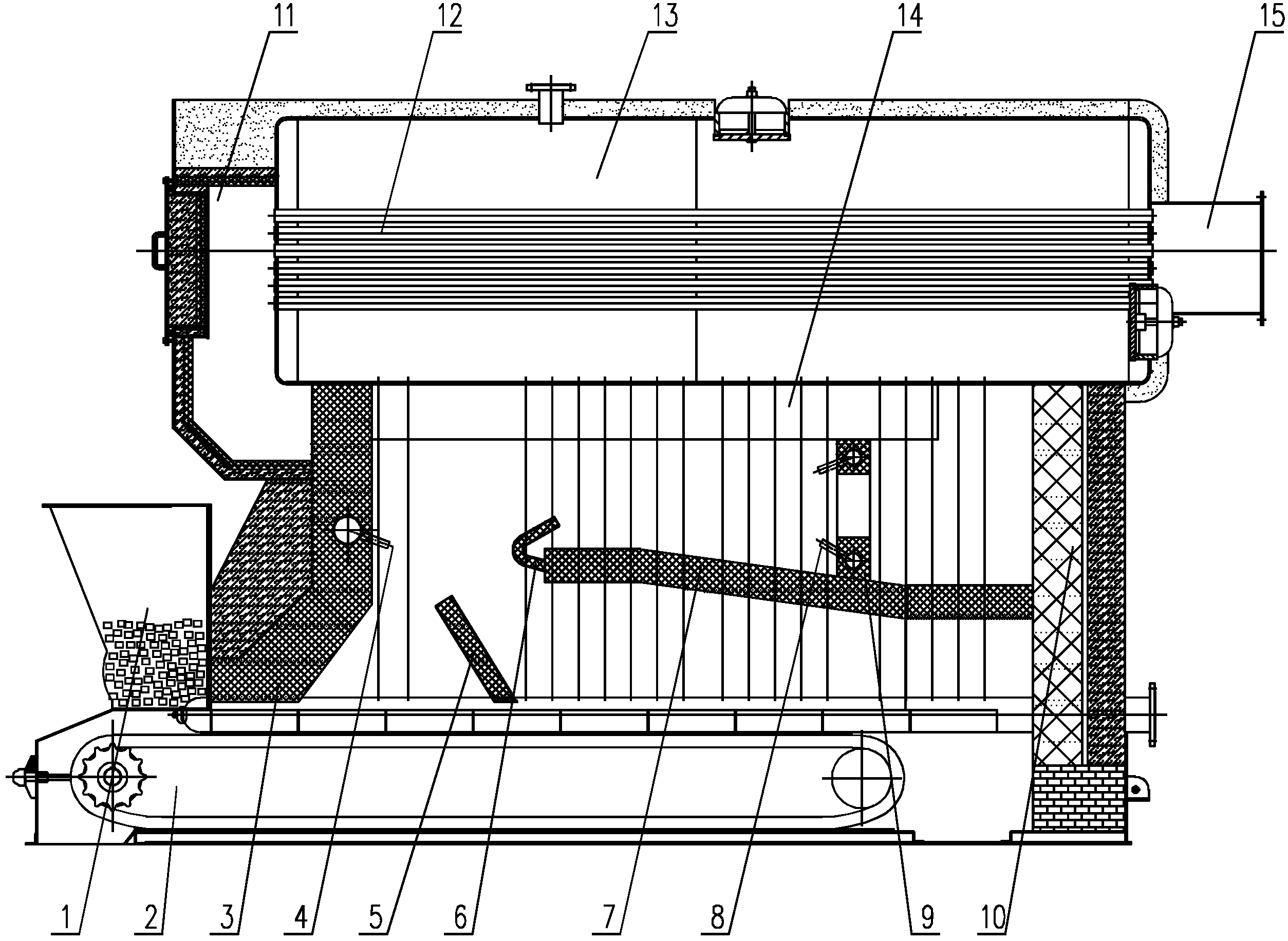

[0029] Such as figure 1 , 2 As shown, a biomass low-nitrogen direct-fired boiler includes a furnace. A boiler body 13 is arranged on the upper part of the furnace. The front and rear ends of 13 are respectively provided with a front smoke box 11 and a rear smoke box 15. The cavity of the furnace is surrounded by the front arch 3, the rear wall 10, the boiler body 13 and the chain grate 2. (The partition arch 5 is used to form the reaction microenvironment of the high-temperature pyrolysis zone, block the primary air distribution, and play the role of spreading the fuel), the rear arch 7, the airfoil flue 14 and the smoke separation wall 9, and the front end of the rear arch 7 There is a flue gas deflector 6, the smoke partition wall 9 is arranged on the upper part of the rear arch 7, the airfoil flue 14 is arranged on the upper area of the furnace c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com