Production technology of biomass boiler ash organic fertilizer

A biomass boiler and production process technology, applied in the directions of organic fertilizers, fertilizers made from biological waste, fertilization devices, etc., can solve problems such as difficulty in meeting market demand, lack of large-scale industrial production capacity, etc., and achieve outstanding economic benefits, Low cost, thriving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

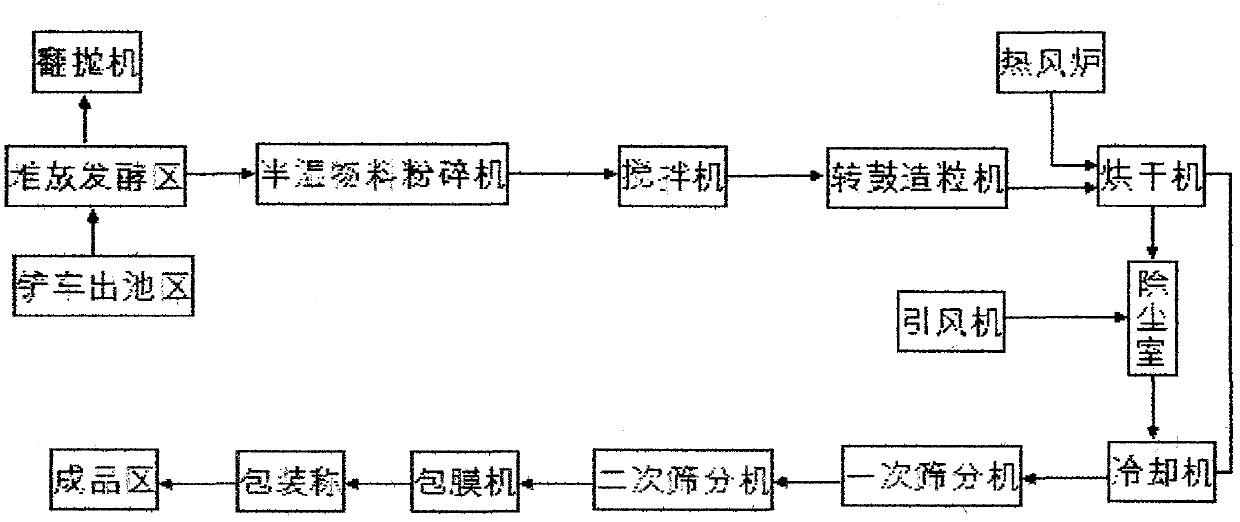

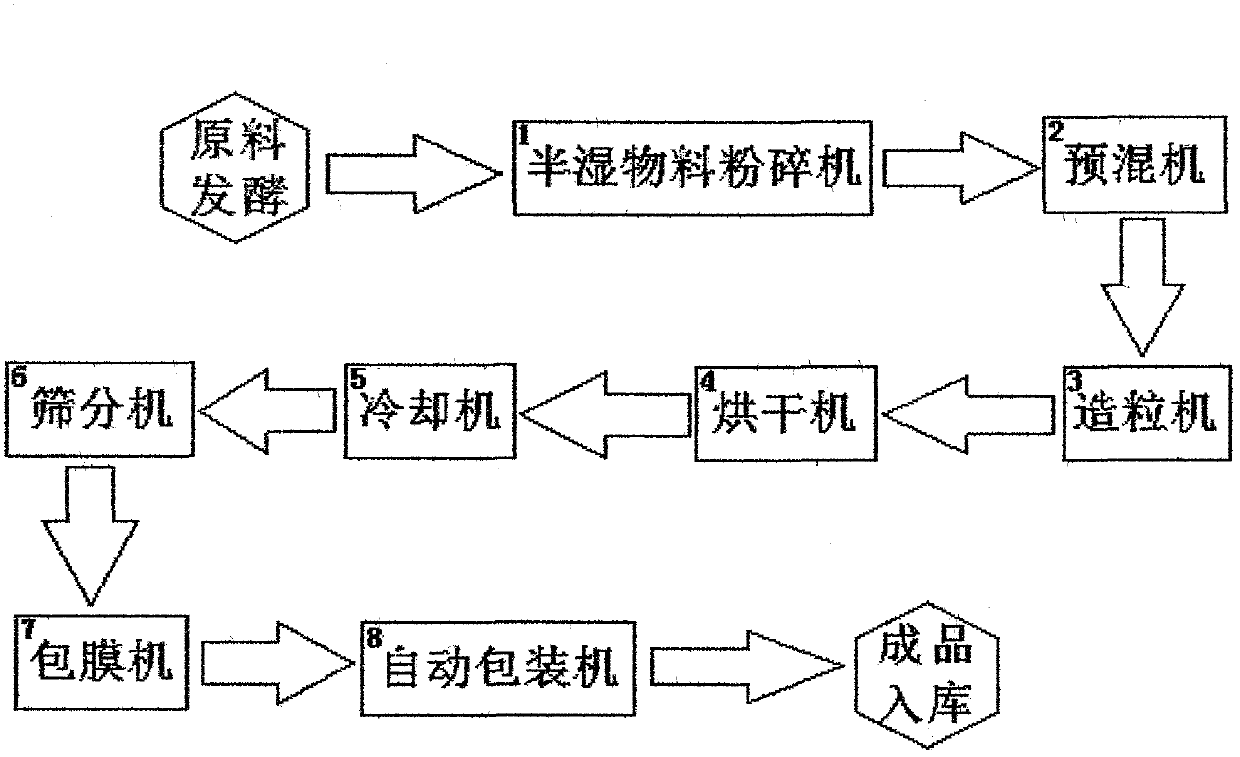

[0012] Embodiments of the present invention are specifically described below in conjunction with the accompanying drawings:

[0013] Reference attached figure 1 , in the production process of the embodiment of the present invention, the main raw material is ash slag pyrolyzed by a biomass boiler [weight ratio before pyrolysis: straw 70%, sawdust 20%, fruit shell 8%, calcium oxide 2%, high temperature The main component after cracking is potassium carbonate (K 2 CO 3 ) and calcium, magnesium, sulfur, phosphorus, iron elements, and also contain a small amount of trace elements such as boron, aluminum, manganese], and the auxiliary raw materials use fermented animal manure organic fertilizer raw materials. The production process includes seven steps: ①stacking and fermentation, ②material crushing, ③mixing ingredients, ④drum granulation, ⑤drying, ⑥screening, and ⑦packing and storage. The steps are connected sequentially.

[0014] The production process includes (1) fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com