Biomass boiler control system

A biomass boiler and control system technology, applied in the field of boiler equipment, can solve the problem of no boiler monitoring, and achieve the effects of ensuring safe production, realizing automatic control, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The biomass boiler applicable to this embodiment includes a combustion chamber, an induced draft fan, a blower, a star feeder, a star feeder, a steam drum, a water pump, a grate machine, and a slag remover. Among them, the combustion chamber is also called the furnace, which is the place where biomass particles are burned; the induced draft fan draws air to the outside of the combustion chamber to generate negative pressure in the combustion chamber; the blower delivers air to the combustion chamber; the star feeder adds biomass particles to the combustion chamber ; The steam drum stores water and water vapor; the water pump delivers water to the steam drum; the grate machine and the slag remover are used for slag removal.

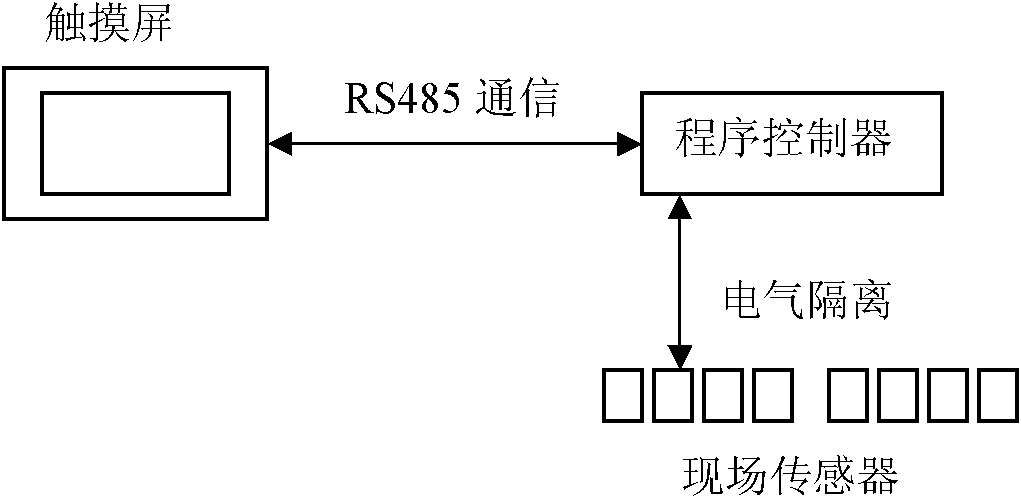

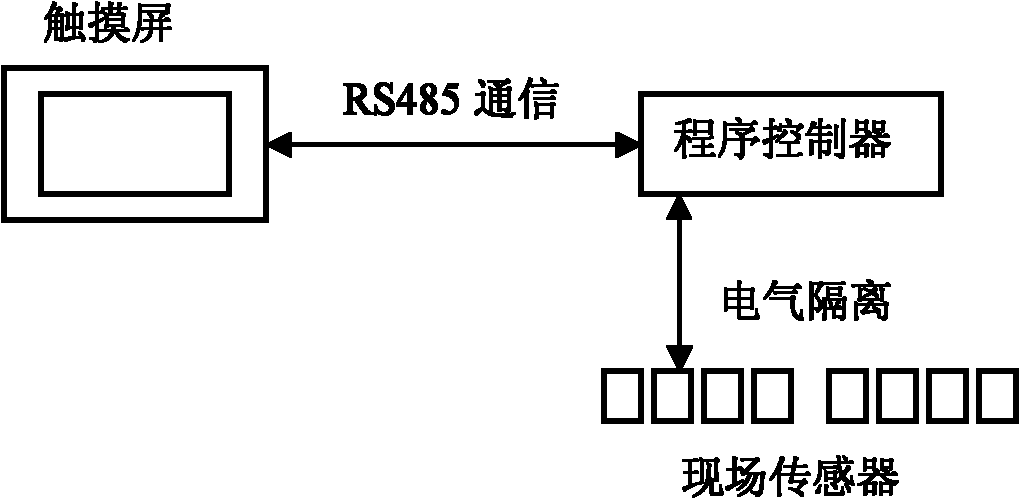

[0039] Such as figure 1 As shown, the control system of this embodiment includes various sensors, a program controller and a control cabinet. Among them, the control cabinet is used to install the program controller, the corresponding power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com