Rotary plough for gasifiers

a gasifier and rotary technology, applied in the field of gasifiers, can solve the problems of erosion patterns on the gasifier walls and components, outward forces and erosion patterns on the gasifier walls and other parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

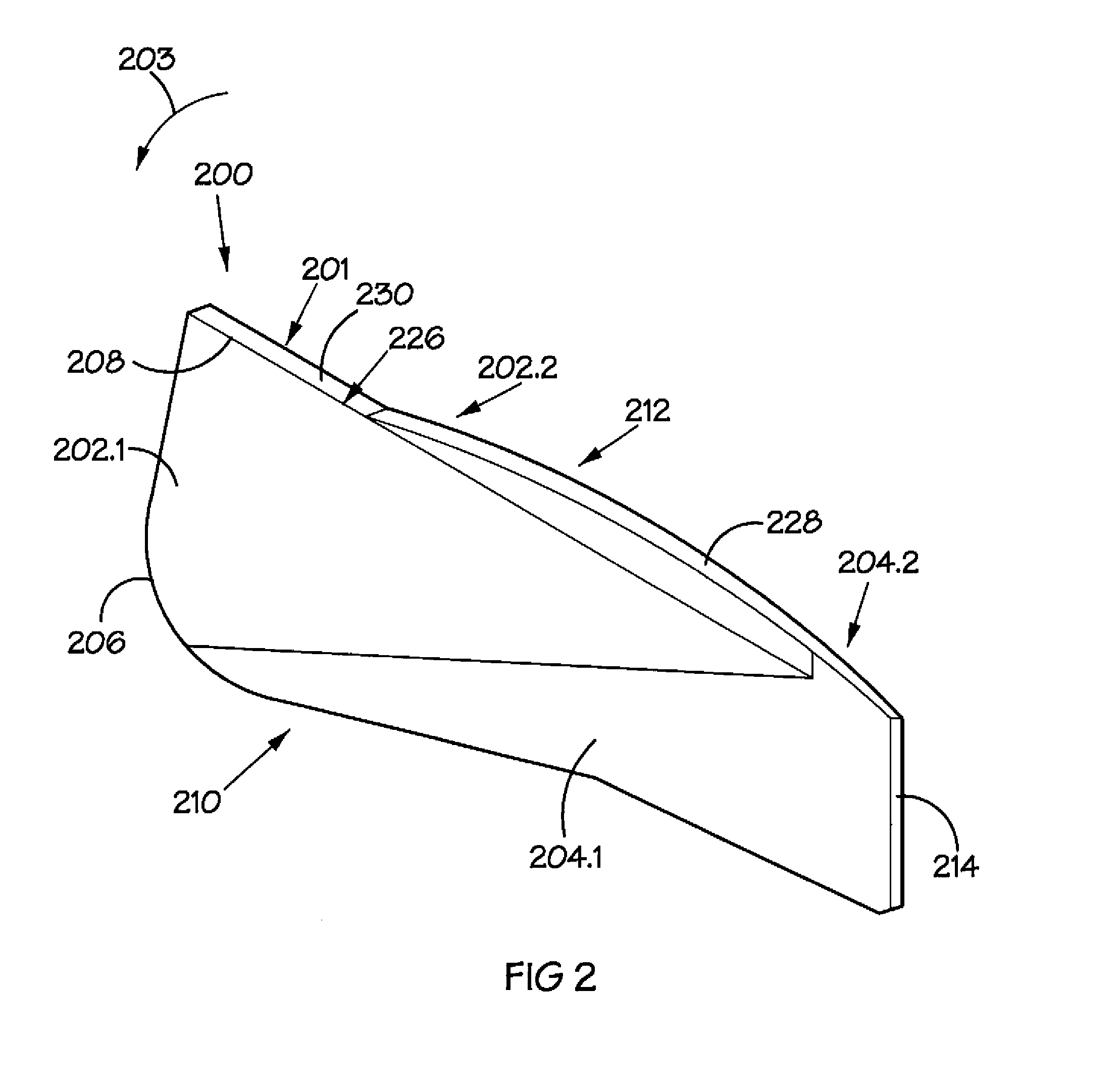

[0089]The inventor has conducted modelling studies to determine the solids flow characteristics of the short straight plough and the Sasol® Banana Plough™ of the prior art as well as the plough 200. The results are reflected in FIGS. 9, 10 and 11. In these figures, the shade indicates the velocity of the ash particles at a point, with the light grey shades representing slow moving or stationary ash particles, and the darker shades representing particles which have a faster velocity.

[0090]Referring in particularly to FIG. 9A (short straight plough) and FIG. 10A (Basal® Banana Plough™), it can be seen that in forward operation (indicated by reference numerals 301 and 401) the ash particles at the leading face of the plough move the fastest and are therefore also responsible for the greatest degree of wear on the plough and the gasifier walls. When the short straight plough is operated in reverse mode (indicated by reference numeral 302 in FIG. 9B), almost all of the ash particles rema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com