Compound combustion boiler

A boiler and furnace technology, applied in the field of composite combustion boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

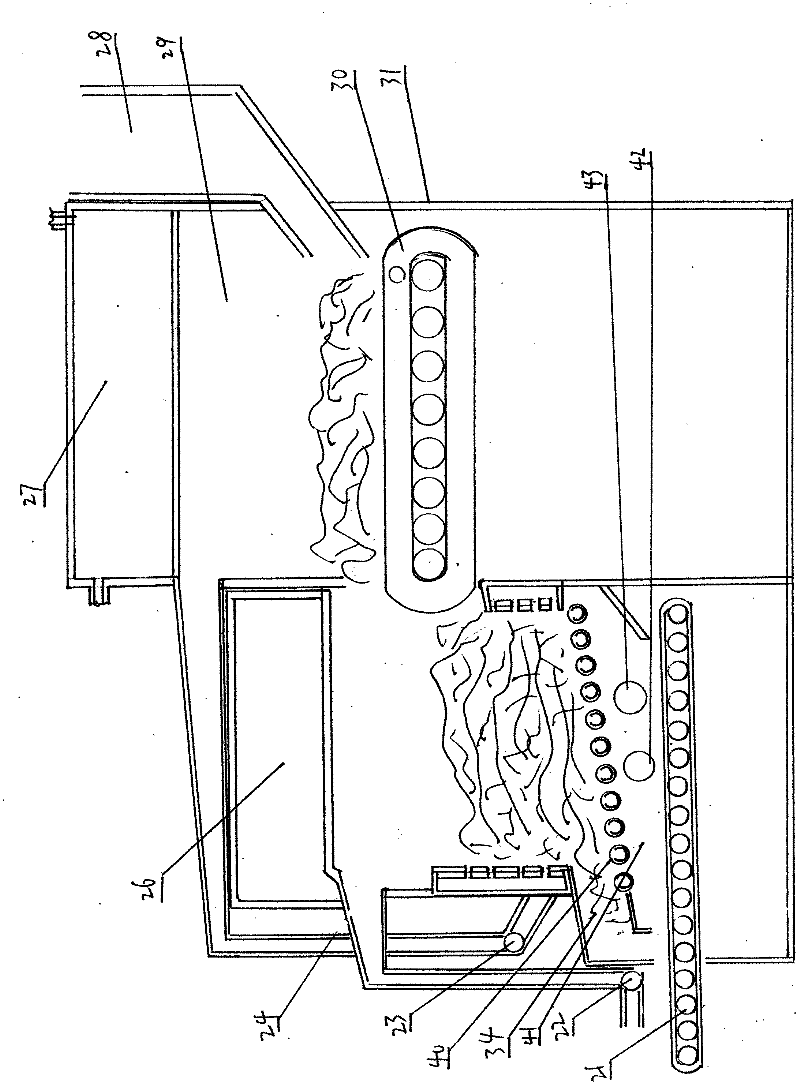

[0038] Such as figure 1 The composite combustion boiler shown in the first embodiment of the present invention includes a boiler 31 and a composite furnace 24. The fuel is sent to the fire grate 30 in the combustion chamber 29 of the boiler through a feeding device 28 for combustion, and then passed through a box-type heat collector. 27 produces hot water or steam, and the burnt slag is discharged from the boiler 31 through the fire grate 30 and enters the rotary grate 40 of the composite furnace 24 for combustion, and then produces hot water or steam through the box-type heat collector 26, and the fuel in the boiler 31 The smoke and dust discharged during combustion are introduced into the smoke return chamber 41 of the compound furnace 24 through the return smoke fan 23 and the return smoke port 42, mixed with the air pressed in by the fan through the air inlet 43, and passed through the rotating furnace bar 40 in a higher furnace. The secondary combustion is carried out in ...

Embodiment approach 2

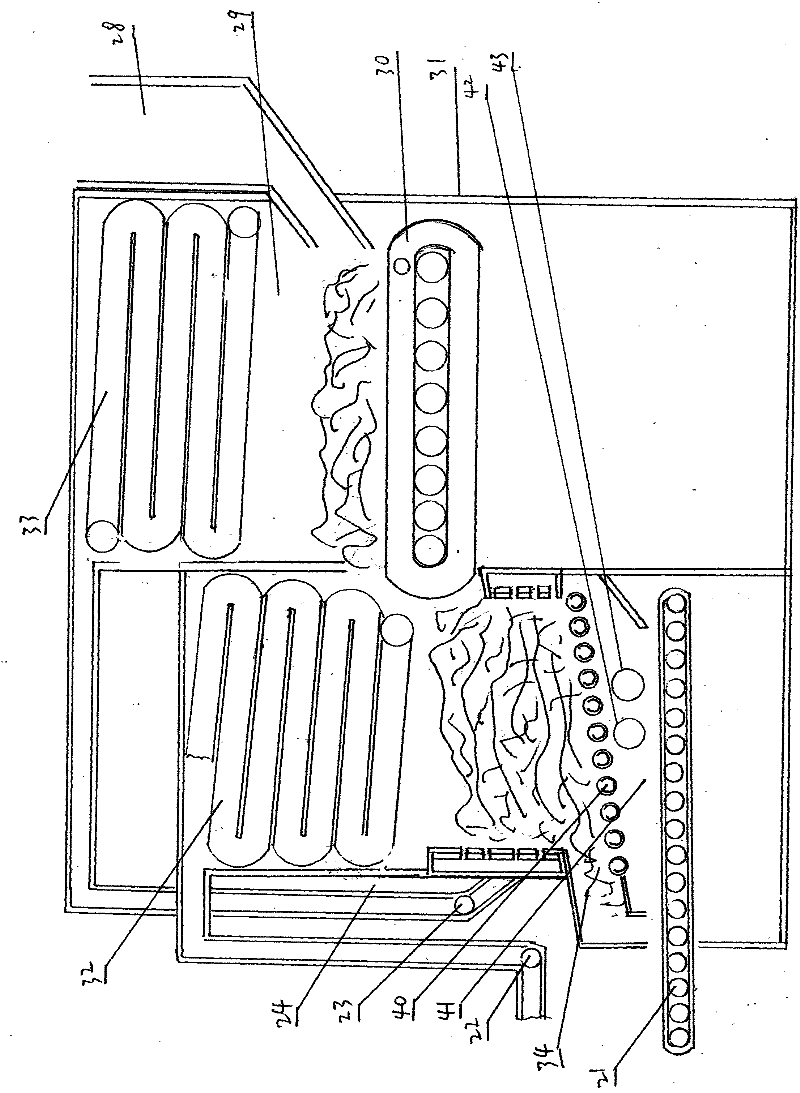

[0041] Such as figure 1 The composite combustion boiler shown in the first embodiment of the present invention includes a boiler 31 and a composite furnace 24. The fuel is sent to the fire grate 30 in the combustion chamber 29 of the boiler through a feeding device 28 for combustion, and then passed through a tubular heat collector 33 Hot water or steam is produced, and the burned slag is discharged from the boiler 31 through the fire grate 30 and enters the rotary grate 40 of the composite furnace 24 for combustion, and then the hot water or steam is produced through the tubular heat collector 32, and the fuel in the boiler 31 is burned The flue dust discharged during the time is passed through the smoke return fan 23, and the smoke return port 42 is introduced into the smoke return chamber 41 of the composite furnace 24, mixed with the air pressed in by the fan through the air inlet 43, and passed through the rotary furnace bar 40 at a higher furnace temperature. The seconda...

Embodiment approach 3

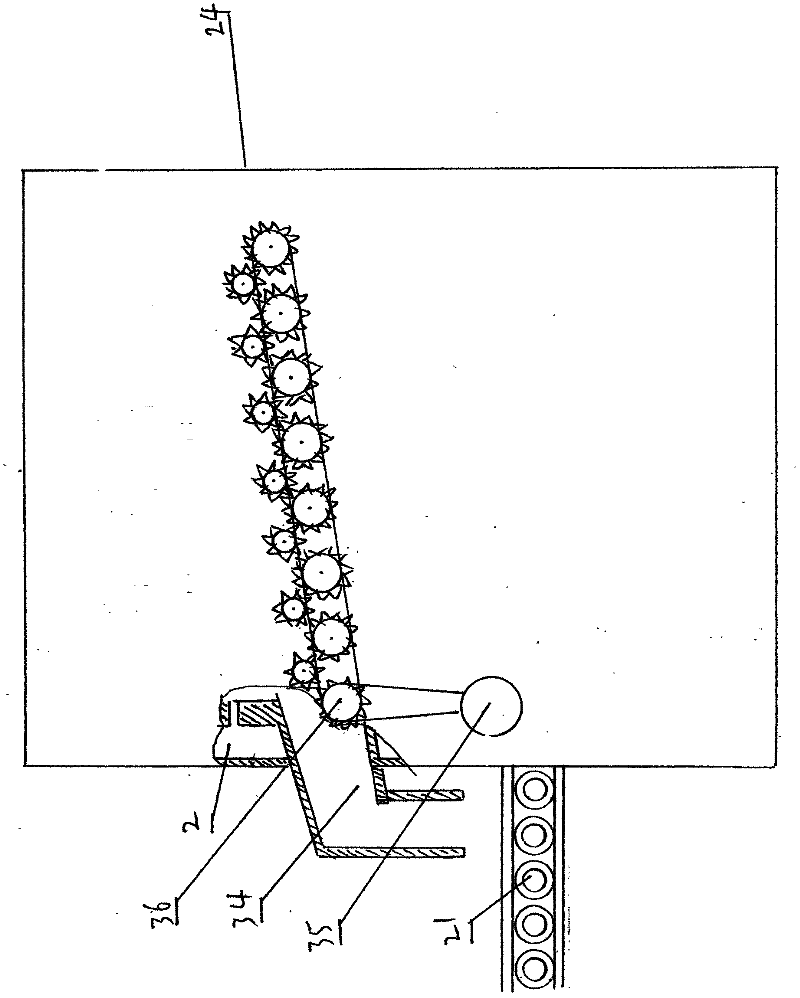

[0044] Such as image 3 The composite combustion boiler according to the third embodiment of the present invention includes a composite furnace 24, a transmission motor 35, a transmission device 36, a coarse slag discharge port 34, and a slag discharge device 21. After the slag is further burned in the composite furnace 24, it passes through the transmission motor 35 Drive the transmission device 36 to rotate, thereby driving the rotating furnace bar to rotate and discharge the slag out of the composite furnace 24, wherein the slag with smaller particles directly falls from the gap between the rotating furnace bars, and the larger pieces of slag are rotated to the coarse slag discharge port through the rotating furnace bar 34 is discharged to the slagging device 21 for discharge.

[0045] According to the above structure, due to the limited space between the rotating bars, it is impossible for large pieces of slag to fall from the space between the rotating bars. By opening th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com