Novel biomass burner rotary fire grate

A biomass and burner technology, applied in the direction of rotary grate, oscillating grate, grate, etc., can solve the problems of material leakage, slag blockage, blockage, etc., to improve work efficiency, save input costs, and design The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

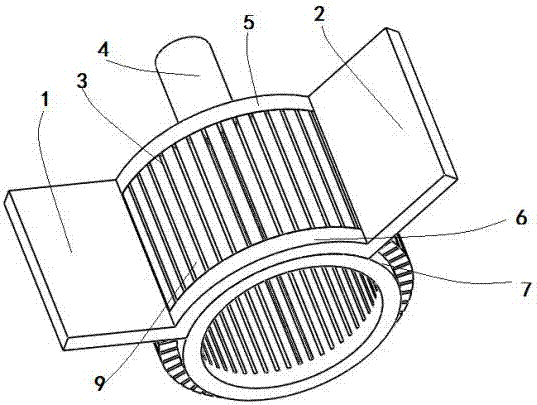

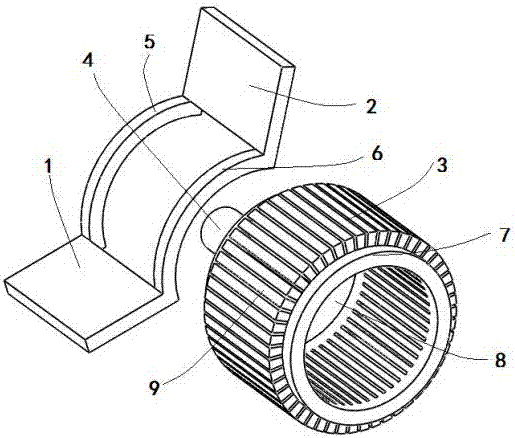

[0016] A new type of biomass burner rotary grate, including left baffle 1, right baffle 2, strip hole 3, rotating shaft 4, rear baffle 5, front baffle 6, cylinder 7, circular plate 8, Bearing cylinder 9, a cylinder 7 is arranged in front of the bearing cylinder 9, a front baffle 6 is arranged above the cylinder 7, a left baffle 1 is arranged on the left side of the front baffle 6, and a right baffle 2 is arranged on the right side of the front baffle 1 A circular plate 8 is fixed behind the carrying cylinder 9, a rotating shaft 4 is fixed on the rear side of the circular plate 8, a rear baffle 5 is fixed above the circular plate 8, and several strip holes 3 are evenly distributed on the carrying cylinder 9. The motor drives the rotating shaft 4 to rotate, so that the bearing cylinder 9 rotates repeatedly along the axis, and the forwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com