Automatic feeding and ash removing incinerator

An automatic feeding and automatic ash cleaning technology, which is applied in the direction of incinerators, oscillating furnace grates, furnace grates, etc., can solve the problems of ash and dust pollution in the air, and achieve the effects of good blocking effect, high processing efficiency and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

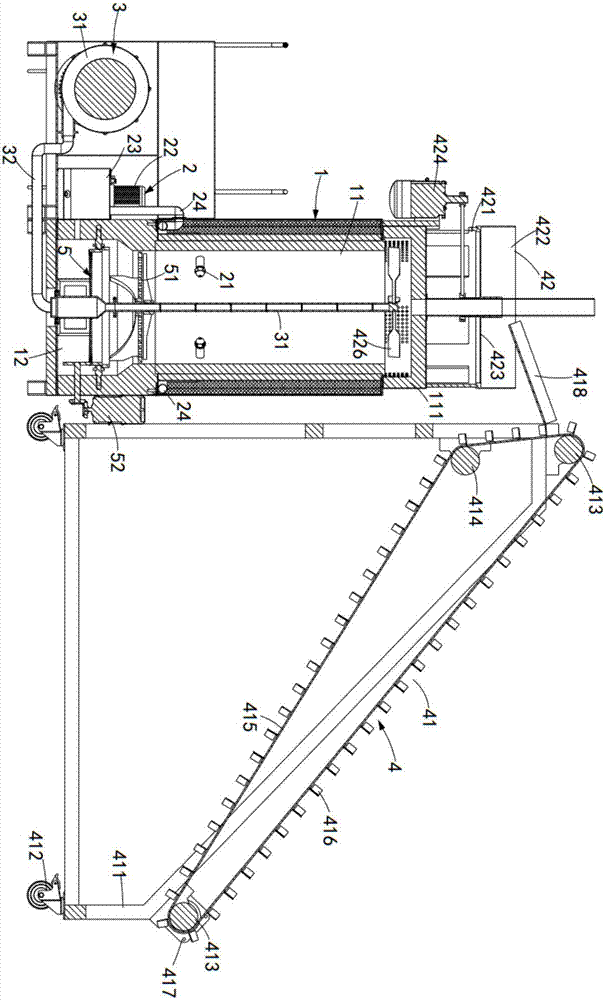

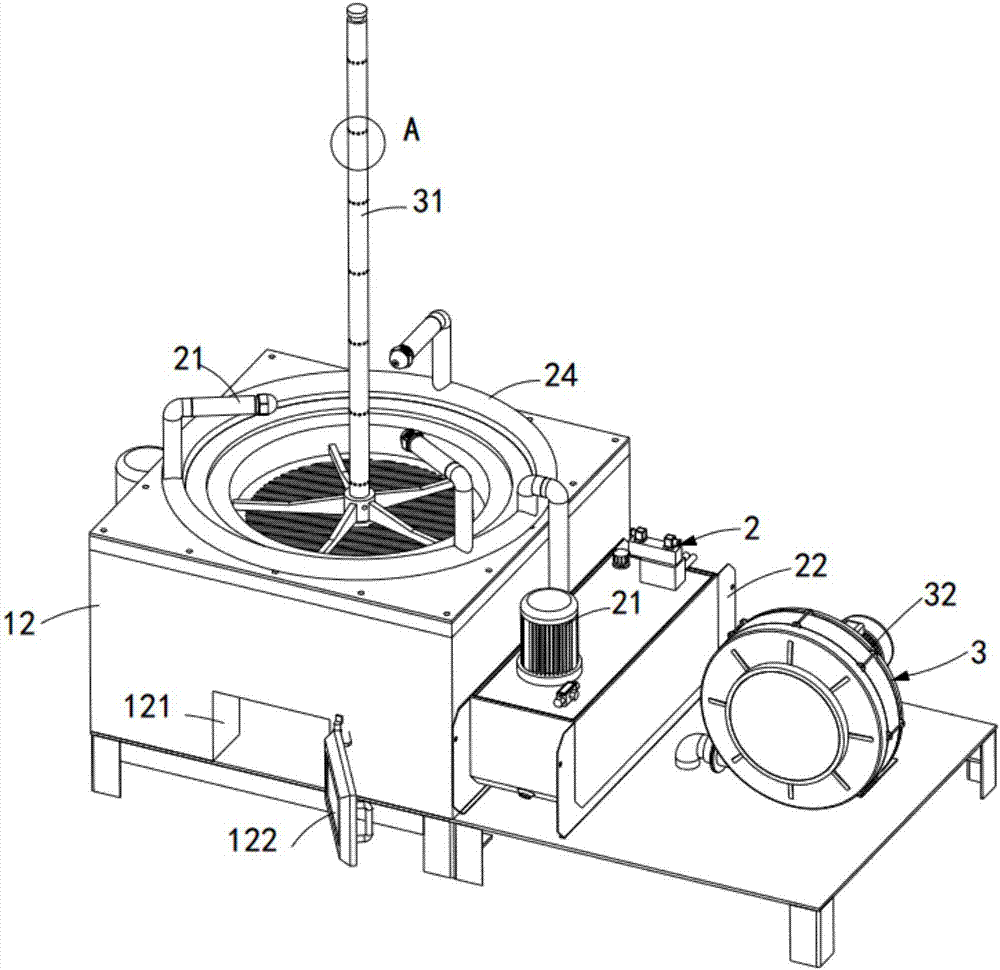

[0063] like figure 1 , image 3 and Figure 4 As shown, an automatic feeding and ash removal incinerator, including:

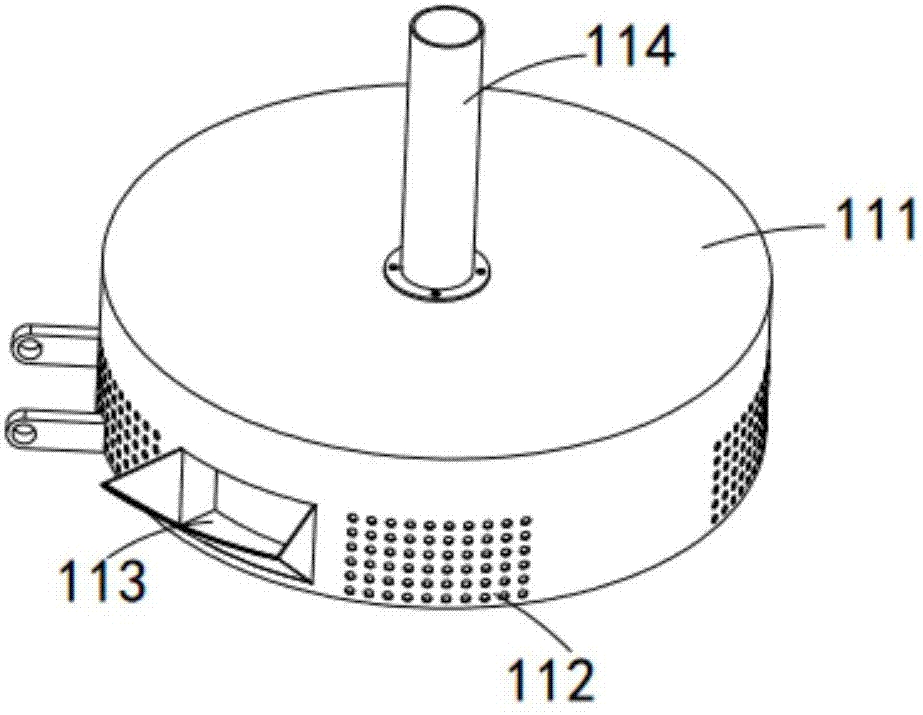

[0064] Furnace body 1, the furnace body 1 is provided with an incineration area 11 located at its upper part and an ash storage area 12 located at its lower part, the said incineration area 11 is set in a cylindrical shape, and the said ash storage area 12 is set in a square shape;

[0065] An oil injection mechanism 2, the oil injection mechanism 2 is arranged on one side of the ash storage area 12, and a number of oil injection nozzles 21 at the end thereof are arranged on the side wall of the incineration area 11 through the side wall of the incineration area 11 bottom, and the fuel injection nozzles 21 are equidistantly arranged in the circumferential direction of the incineration zone 11;

[0066] Air injection mechanism 3, said air injection mechanism 3 is arranged on the other side of said oil injection mechanism 2 relative to said furnace body 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com